Choosing the right material frequently comes down to analyzing strength, weight, and performance. When you research tungsten vs titanium, you will observe that both metals deliver special qualities for different applications. Titanium is known for being lightweight yet strong, while tungsten is heavier and extremely hard.

Their comprehensive differences help you choose whether you need durability, strength, resistance, or lightweight strength. In this blog, you will learn about titanium and tungsten, the types, advantages, disadvantages, and how to choose between them.

O que é o titânio?

Titanium is a transition metal that looks silver in color. It was founded in the year 1791 and was named after the Titans in Greek mythology for its strength. Its very great strength-to-weight ratio makes titanium a key option for use in the aerospace, automotive, marine, and medical industries. Unlike many other metals, titanium does not corrode easily, even when subjected to saltwater or chemicals.

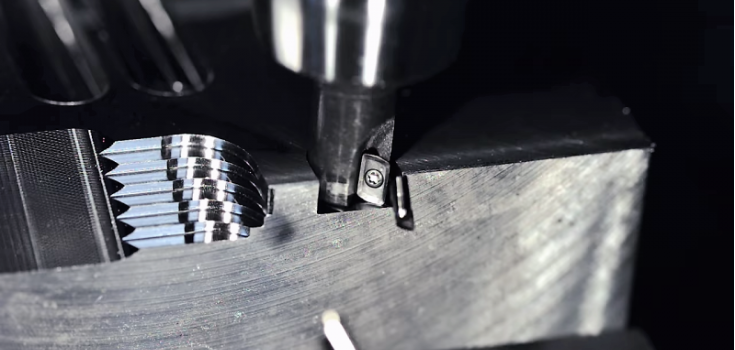

It is biocompatible, meaning your body will accept it. Hence, surgeons use it in implants. Even though it is very lightweight. Titanium can take a lot of stress before deforming. However, it could be CNC-machined or even advanced 3D printing, depending on the application end.

Different Types of Titanium

Titânio is available in a massive number of grades and alloys, all with their own distinct performance. The most common types are:

Commercially Pure Grades (1–4)

These grades differ in durability and corrosion resistance. Grade 1 is the most flexible, and Grade 4 is the most resistant to breakage. These grades find applications in chemical processing, marine devices, and medical instrumentation.

Ti 6Al-4V (Grade 5)

The most commonly used titanium alloy, due to its good durability and resistance. They are often found in the aerospace sector, sports equipment, and automobile parts.

Ti 6Al-4V ELI (Grade 23)

It is also known as surgical titanium. It is one of the best options for biocompatibility, combined with considerable application in dental and orthopedic implants.

Ti 3Al-2.5V (Grade 9)

It combines strength and weldability and is suitable for tubing in aerospace and marine environments.

Ti 5Al-2.5Sn (Grade 6)

They offer excellent weldability and stability at high temperatures and are used for aircraft frames.

Each grade has a specific use. Therefore, allowing you to be selective in your titanium choice for projects in which performance is an important factor.

Advantages and Disadvantages Of Titanium

Vantagens

- Strong, still lightweight, safe for most applications where high-strength steel is used.

- Unique performance under corrosive environments such as sea and acidic media.

- Biocompatible for safe usage with medical implants.

- By virtue of having a high strength-to-density ratio, applications include aerospace and automotive designs.

- 100% recyclable, thus cutting down on waste and impacts on the environment..

Desvantagens

- Titanium is very costly compare to other present metals, like aluminum or steel.

- The reactivity of titanium is extremely high, and it is difficult to weld or cast.

- Availability could be at length in certain regions, so that delays may occur for already planned projects.

- Challenging to machine compared to smoother metals.

- Needed refined processes like the Kroll method for removal and refinement.

What is Tungsten?

Tungsténio is also called Wolfram and is a very dense metal discovered in 1783 by Spanish chemists Fausto and Juan José de Elhuyar. Tungsten translates into "heavy stone" in Swedish. Tungsten is famous for having the highest melting point of all metals (3422°C) and for being extremely hard.

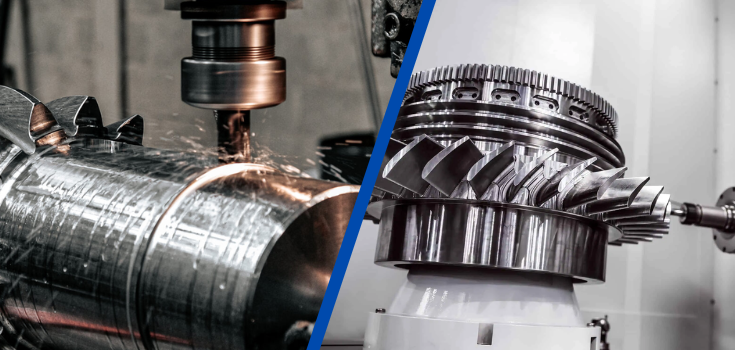

This metal is found in cutting tools, electrical contacts, light bulb wires, and even jewelry. Its hardness gives it resistance to wear, while its density makes this metal useful in industries such as defense, focusing on weight and impact resistance.

Different Types Of Tungsten

Tungsten can be found in various forms, each designed for specific industries:

Carboneto de tungsténio

The most common type is mostly used for cutting tools, drill bits, and jewelry. It is a combination of hardness and chemical resistance.

Cemented Carbide

Carboneto de tungsténio mixed with cobalt or other metals is primarily used in mining, machining, and heavy-duty tools.

Pure Tungsten

Very well known for its high melting point. Pure tungsten is used in electrical applications like filaments and heating elements, and even in X-ray targets.

Tungsten Heavy Alloys

Tungsten Heavy Alloys contain nickel, copper, or iron. That is why it is valuable for aerospace, defense, and medical shielding.

Tungsten-Based Chemicals

Found in special industries such as ceramics, catalysts, and pigments.

Selecting the right kind of tungsten certifies that its different properties synchronize with your project requirements.

Advantages and Disadvantages Of Tungsten

Vantagens

- It provides high melting point advantages for ultrahigh-temperature applications.

- Unique hardness and scratch-resistant properties, stronger than most metals.

- High-density material, used in military armor, radiation shielding, and ballast for racing cars.

- Resistant to damage, making it excellent for tools.

- Retains stability in extreme heat without losing strength.

Desvantagens

- Extremely heavy. Therefore, it blocked its use where lightweight materials are preferred.

- A breakable nature can cause a crack or shatter on impact.

- More expensive than common metals like steel or aluminum.

- Difficult to weld, cut, and machine due to its hardness.

- It cannot be resized, limiting its use as jewelry.

Titanium and Tungsten Properties Comparison Table

| Imóveis | Titânio | Tungsténio |

| Densidade | 4.51 g/cm³ | 19.25 g/cm³ |

| Ponto de fusão | 1,668°C | 3,422°C |

| Resistência à tração | ~240–1,200 MPa | ~980 MPa (min) |

| Resistência à corrosão | Excelente | Moderado |

| Biocompatibilidade | Elevado | Baixa |

| Peso | Leve | Very Heavy |

General Comparison Table of Titanium and Tungsten

| Caraterística | Titânio | Tungsténio |

| Scratch Resistance | Moderado | Muito elevado |

| Crack Resistance | Elevado | Low (Brittle) |

| Custo | Expensive but less than tungsten | Higher overall cost |

| Aplicações | Aerospace, Medical, Sports Gear | Tools, Electronics, Jewelry, Defense |

| Soldabilidade | Difficult but possible | Very Difficult |

| Jewelry Use | Lightweight, comfortable | Scratch-resistant, heavy |

Tungsten vs Titanium - Which One Is Better?

The choice between tungsten and titanium depends on the specific needs you have in mind. Tungsten is good if you want anything immensely hard, scratch-proof, and very dense. It works great for cutting tools, armor, and heavy-duty applications. It has some limitations in specific industries because of its weight and weakness.

Compared to tungsten, titanium provides a wonderful combination of strength, corrosion resistance, and light weight. It stands out in the aerospace, automotive, and medical implant sectors.

If you want something that would have the attributes of strength and comfort, then titanium fits most engineering and lifestyle applications these days. For incredible hardness or high-temperature applications, tungsten would be the one.

Conclusão

Comparing tungsten with titanium establishes two metals with contrasting properties. Titanium is strong, light, and biocompatible, while tungsten is dense, hard, and heat-resistant. Your choice will depend on which performance feature you require. From aerospace to jewelry, the two metals play important roles in many applications.

DEK specializes in machining titanium and tungsten. Contact us, and we will review your needs. Our team can help with material selection, engineering design, and custom-part manufacturing. Reach out to us today to explore the best solution for your business needs.