- Início

- New Energy

Precision Parts Manufacturing for New Energy Industry

DEK specializes in precision parts manufacturing for the new energy industry, providing rapid prototyping and on-demand production for renewable energy and new energy applications.

From new energy vehicle components to energy storage equipment, we deliver high-quality, durable, and consistently reliable parts to global new energy industry clients. We can rapidly process complex parts with tight tolerances controlled within +/- 0.005 mm, utilizing a variety of production-grade materials and surface treatment options.

- In-house Quality Control

- Suporte de Engenharia 24/7

- Instant Quotes and DFM Feedback

- ISO 9001:2015 and ISO 14001:2015 certified.

- Rotação rápida, prazo de entrega curto, não MOQ

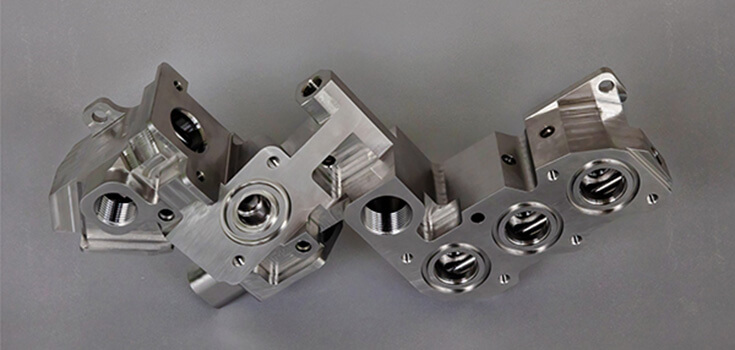

Precision CNC Machined Components for New Energy Industry

DEK is renowned for its superior quality and comprehensive services, offering reliable, precise, and flexible custom solutions tailored to the specific needs of the new energy industry.

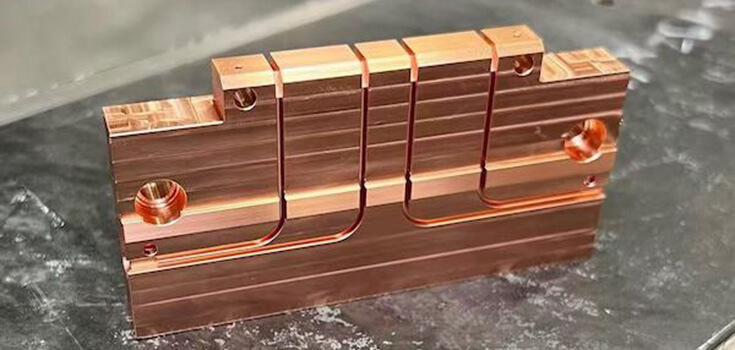

As an ISO 9001 certified manufacturer, DEK specializes in high-precision parts for energy storage equipment, achieving tight tolerances of up to ±0.005mm. We strictly adhere to new energy industry standards, excelling in machining aluminum alloys, stainless steel, alloy steel, copper, and engineering plastics, ensuring that every part produced by DEK offers durability, corrosion resistance, and wear resistance.

Additionally, we provide surface treatments such as anodizing, electroplating, nitriding, and PVD coating. Our typical applications include gearboxes, jigs and fixtures, generator parts, drill rig components, nozzles, impellers, and wind and water turbines. All quality inspections are conducted in-house, and we provide CMM inspection reports, FAI reports, and material certificates.

New Energy Part

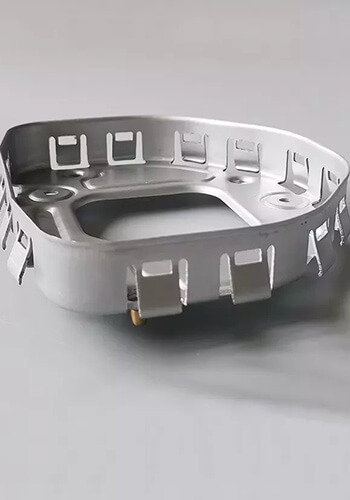

New Energy Vehicle Part

New Energy Metal Part

Bicos

Reducer Housing

Shaft Housing

New Energy Component Capacidades de fabrico

Maquinação CNC de precisão

DEK possesses multi-axis CNC machining, precision turning, and complex component manufacturing capabilities, including milling, grinding, turning, boring, and reaming, meeting the stringent requirements of new energy applications. It is ideal for manufacturing hangers, gearboxes, main shaft housing, bearing seats, solar tracker mounts, and junction box covers.

Whether you need a prototype or are seeking a reliable partner for small to medium batch production, DEK focuses on using production-grade materials and implementing strict in-house quality control to provide one-stop, flexible, and efficient solutions.

Fabrico de chapas metálicas

DEK specializes in machining high-quality custom sheet metal parts for the marine industry, including battery tray, ESS cabinet, liquid cooling plate, PDU enclosure,and EV charger pile enclosure, providing reliable structural support and protection for your key components.

We offer a variety of sheet metal materials, including stainless steel, aluminum, and steel. From instant quotes to rapid production, you can receive hundreds of premium sheet metal parts in just days. Additionally, we provide surface treatment options such as brushing, anodizing, and coating to meet your parts' high demands.

Impressão 3D industrial

DEK provides high-quality additive manufacturing services, enabling you to rapidly create prototypes at low cost and produce durable, wear-resistant parts with complex geometries on demand.

We can provide a variety of metals and plastics, including ABS, nylon, TPU, PC, and composites, for printing solar panel mounting brackets, microinverter housings, jigs and fixtures, spare parts, and wind turbine blade prototype. Additionally, we can offer surface treatments required for the project.

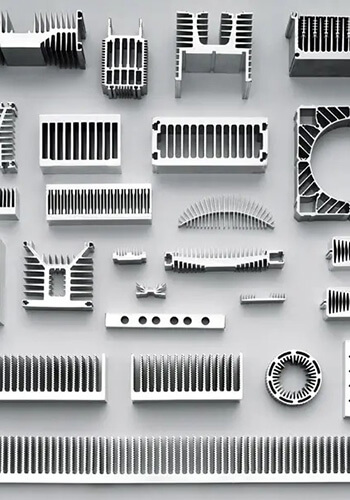

Extrusão de alumínio

Industrial aluminum profiles, with their high strength, lightweight, corrosion resistance, and exceptional design flexibility and modularity, have become indispensable structural materials in the new energy industry.

DEK provides high-quality aluminum extrusion parts for the new energy industry. Our classic cases include battery module frames, solar panel frames, and heat sink. We can flexibly handle your project, offering cost advantages in batch production.

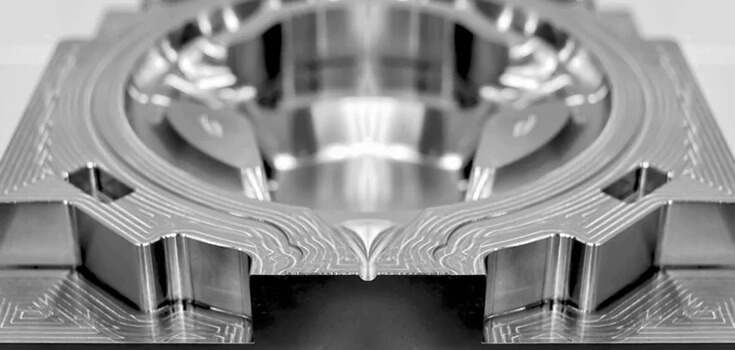

Fundição injectada

With the advantages of high efficiency, high precision, lightweight design, and cost control, die-cast components are widely used in critical fields such as new energy vehicles, energy storage systems, and solar and wind power generation.

DEK provides high-quality die-cast parts for the new energy industry, including motor housings, gearbox housings, and inverter enclosures. We can flexibly handle your project, offering cost advantages in mass production.

Materiais

Materiais Opções

Alumínio

Aluminum and its alloys are among the most widely used metals in the new energy sector, serving as a core choice for achieving lightweight designs. They are highly suitable for manufacturing battery pack housings, motor housings, reducer housings, and controller enclosures.

High-strength Steel

High-strength steel is widely used in the new energy industry due to its high strength, low cost, and good processability, making it indispensable for critical safety structural components such as chassis structural parts, drive shafts, and suspension parts.

Cobre

Copper and its alloys are primarily used in the new energy industry due to their excellent electrical and thermal conductivity, as well as their ease of processing and welding. They are highly suitable for manufacturing busbars, motor rotors, contact pins, motor terminals, and thermal baseplates.

Plásticos de engenharia

Engineering plastics play a crucial role in insulation, lightweight design, and functional integration. They are commonly used to manufacture connectors, battery module brackets, end plates, charging gun housings, PV junction box housings, and motor sensor brackets.

Instantâneo & Citações exactas

Não utilizamos ferramentas de cotação automatizadas em linha, porque são muito imprecisas. As plataformas de cotação em linha baseiam-se apenas em cálculos baseados em montantes de corte e coeficientes fixos, não tendo em conta as nuances reais do processamento, tais como a deformação do material após o tratamento térmico, requisitos de tolerância apertados, retificação após o tratamento térmico, etc. Consequentemente, os cálculos automáticos de preços podem levar a imprecisões, aumentando, em última análise, os seus custos.

Mas pode ficar descansado com a DEK!

Os nossos orçamentos são económicos e precisos porque temos uma equipa de engenheiros mecânicos profissionais que analisam meticulosamente cada desenho. Estes engenheiros têm mais de 10 anos de experiência e possuem conhecimentos profundos em programação, funcionamento de máquinas, pós-processamento, propriedades dos materiais e muito mais. Garantimos que receberá orçamentos exactos no prazo de 6 horas.

Porquê escolher Os nossos serviços

A produção de peças de alta qualidade num só local permite-lhe poupar tempo e dinheiro.

Capacidades de engenharia

Prazo de entrega rápido

Controlo de qualidade

Acabamentos de superfície

Montagem de precisão

Packaging and Logistics

O nosso Processo de encomenda

Enviar RFQ

Enviar RFQ com desenhos 2D/3D e requisitos detalhados por correio eletrónico ou formulário online.

Crítica e cotação

A nossa equipa de engenheiros analisará cuidadosamente cada desenho e fornecerá um orçamento preciso no prazo de 6 horas.

Confirmar a encomenda

Confirme o orçamento, os pormenores e o calendário de entrega e, em seguida, assine o contrato.

Produção

Organizar o processo de produção, iniciar a programação e a maquinagem.

Controlo de qualidade

Controlo de qualidade rigoroso durante a produção e a inspeção final.

Embalagem e expedição

Embale as peças, coloque etiquetas de identificação das peças e inicie a expedição.