Custom Die Casting Service

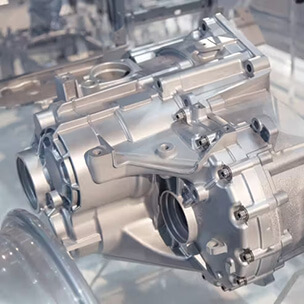

Die casting process offers well-detailed, durable, and high quality die cast metal parts. With the use of specialized molds and techniques. This method produces components with dimensional tolerances.

At DEK, we offer high-quality die casting services while taking note of your unique project requirements. Our services are relatively cheaper than industry standard, thus allowing you to get a durable component at a relatively fair rate. Whether you require a rapid prototype or mass production, we can provide you with flexible solutions.

introdução

Precisão Fundição injectada for Custom Components

DEK offers highly precise, durable die casting services for clients within many industries. Our manufacturing process isn’t just fast but is also efficient and reliable.

With the use of advanced technological machines and tools, teams of experts, and a variety of materials, we deliver the best die casting services across several industries. When fast and effective delivery matters to you, you can count on us. We have streamlined logistics solutions for that. Whether you want just a few components or mass production, we're here to serve– no minimum order quantity.

- Tolerance level of +/-0.01mm

- Fast turnaround time of 4-7 days

- No minimum order quantity

- Ability to handle complex geometries

- ISO 9001:2015 certified

- Variety of material available

Materiais for Die Casting

Metais

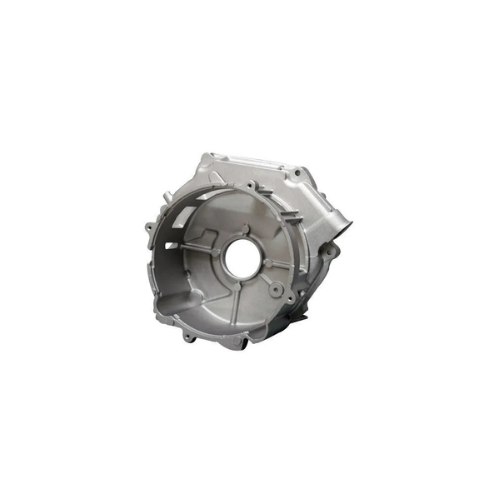

Alumínio

Aluminum is a lightweight, corrosion-resistant metal known for its excellent strength-to-weight ratio and good thermal conductivity. Suitable for die casting due to its quick solidification, making it ideal for producing intricate parts with thin walls.

At DEK, we use aluminum to create durable parts for the automotive, aerospace, and electronics industries. You’ll find us producing aerospace engine enclosures, heat sinks, and transmission covers.

Liga metálica

Aluminum 2024, 5052, 5083, 6060, 6061

Latão

Brass is an alloy of copper and zinc that offers a rich combination of strength, corrosion resistance, and an attractive golden appearance. It’s commonly used in applications where both performance and aesthetics are required.

Our high-quality die casting service allows us to deliver precision components in the plumbing, marine, and decorative hardware industries. We utilise brass in producing valve bodies, marine propeller hubs, and luxury faucet handles.

Liga metálica

Brass 260, C360, Cz121

Bronze

Bronze is a strong, corrosion-resistant alloy composed mainly of copper and tin. It offers excellent wear resistance and performs well in applications where there's exposure to friction.

At DEK, we use bronze to produce high-quality components for marine, industrial, and power systems. You benefit from our precise tooling, excellent dimensional control, and refined surface finishes. Our die casting methods ensure your parts maintain structural integrity, minimal porosity, and consistency across every production run.

Liga metálica

Bronze 544, 841, 932, 954

Cobre

Copper is a highly conductive, durable metal known for its superior thermal and electrical properties. It also resists corrosion and maintains strength under extreme conditions.

At DEK, we leverage copper in die casting to support industries like electronics, automotive, and energy. You can rely on us for consistently accurate parts with excellent thermal transfer and conductivity. Our process ensures tight tolerances, smooth finishes, and the durability needed for critical, high-load applications.

Liga metálica

Copper C101, C110

Chumbo

Lead is a dense, malleable metal with excellent shielding and vibration-dampening capabilities. While its use is limited to specialized applications, it remains essential in sectors that require controlled radiation or sound insulation.

At DEK, we use lead to serve clients in the medical and automotive sectors. Our die casting process produces uniform, high-density parts with reliable sealing and accurate dimensions. You benefit from our advanced finishing techniques, quality assurance, and the ability to deliver precision even in low-volume.

Liga metálica

PbSb10, PbSn30, PbAg1.5

Magnésio

Magnesium is a light structural metal, offering an outstanding strength-to-weight ratio. It provides excellent thermal performance and shock resistance, making it ideal for lightweight yet high-strength applications.

At DEK, we cast magnesium parts for industries such as aerospace, electronics, and transportation. Our die casting technology delivers fine detailing, consistent dimensional accuracy, and excellent repeatability. You’ll receive components with smooth surfaces, reduced weight, and minimal post-processing.

Liga metálica

AZ31B, AZ61B, and AZ91D

Zinco

Zinc is one of the most popular die casting metals due to its excellent fluidity, strength, and ability to cast into intricate shapes. It also offers good wear resistance and dimensional stability.

We utilize zinc in providing highly precise die casting services for automotive, electronics, and consumer industries. We create door lock housings, pressure-tight casings in security hardware, and appliance knobs. Our zinc casting solutions offer tight tolerances, superb surface smoothness, and reduced machining needs.

Liga metálica

Zamak 3

Instantâneo & Citações exactas

Não utilizamos ferramentas de cotação automatizadas em linha, porque são muito imprecisas. As plataformas de cotação em linha baseiam-se apenas em cálculos baseados em montantes de corte e coeficientes fixos, não tendo em conta as nuances reais do processamento, tais como a deformação do material após o tratamento térmico, requisitos de tolerância apertados, retificação após o tratamento térmico, etc. Consequentemente, os cálculos automáticos de preços podem levar a imprecisões, aumentando, em última análise, os seus custos.

Mas pode ficar descansado com a DEK!

Os nossos orçamentos são económicos e precisos porque temos uma equipa de engenheiros mecânicos profissionais que analisam meticulosamente cada desenho. Estes engenheiros têm mais de 10 anos de experiência e possuem conhecimentos profundos em programação, funcionamento de máquinas, pós-processamento, propriedades dos materiais e muito mais. Garantimos que receberá orçamentos exactos no prazo de 6 horas.

As nossas vantagens

Mais de 2300 engenheiros Adoro trabalhar connosco

Alta precisão

Our die casting process is engineered for precision. With advanced equipment and expert technicians, we achieve tolerances as tight as ±0.01mm. This means the parts you receive are accurate, consistent, and ready for high-performance applications.

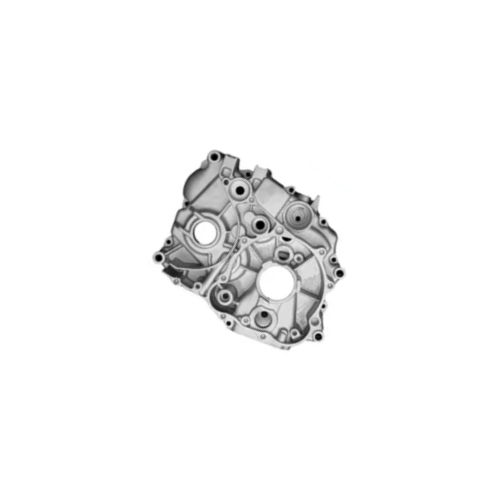

Geometrias complexas

DEK's high-pressure die casting allows us to create intricate parts with thin walls, undercuts, and fine details that other methods can’t handle. You don’t have to simplify your design as we have the tools and expertise to produce exactly what you envisioned.

Certified Quality

Our facilities meet international standards such as ISO 9001:2015, so you can trust that every die cast part is made with strict quality control. You get reliable, consistent quality every time, with traceability and documentation for complete transparency.

Sem MOQ

At DEK, we adapt to your production volume and timeline, making it easier and more cost-effective for startups, custom projects, or trial runs. You get flexibility, fast turnaround, and the same high level of quality, regardless of quantity.

Versatilidade de materiais

You get access to a full range of die casting metals at DEK. You’re not stuck with limited options as we help you choose the best-fit metal based on performance, cost, and application, and ensure it’s cast to perfection.

Custo-eficácia

DEK helps you reduce costs without sacrificing quality. Our efficient tooling, rapid cycle times, and minimal post-processing needs make die casting a highly economical choice, especially for medium to high volumes.

O nosso Processo de encomenda

Enviar RFQ

Enviar RFQ com desenhos 2D/3D e requisitos detalhados por correio eletrónico ou formulário online.

Crítica e cotação

A nossa equipa de engenheiros analisará cuidadosamente cada desenho e fornecerá um orçamento preciso no prazo de 6 horas.

Confirmar a encomenda

Confirme o orçamento, os pormenores e o calendário de entrega e, em seguida, assine o contrato.

Produção

Organizar o processo de produção, iniciar a programação e a maquinagem.

Controlo de qualidade

Controlo de qualidade rigoroso durante a produção e a inspeção final.

Embalagem e expedição

Embale as peças, coloque etiquetas de identificação das peças e inicie a expedição.

Enviar RFQ 222

Crítica e cotação

Confirmar a encomenda

Produção

CQ

Entrega

FAQ

Fundição injectada FAQs sobre a compra

Obter um orçamento exato Para os seus próximos projectos

Independentemente de o seu projeto ser complicado ou simples, de ser de metal ou de plástico, receberá um orçamento preciso no prazo de 6 horas.

Obter um orçamento hojeCompreensão Fundição injectada

O que é a fundição injectada?

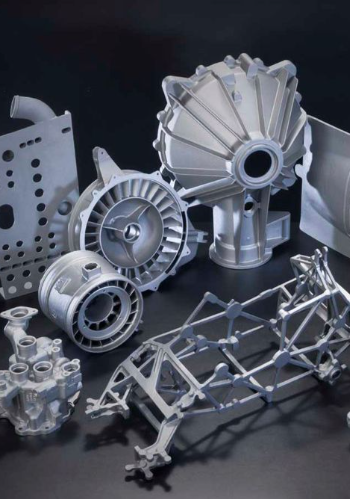

Fundição injectada is a manufacturing process where molten metal is injected into a mold cavity under high pressure to create precise, repeatable metal parts. You typically use this process when you want to produce a large number of parts that are strong, dimensionally accurate, and have smooth surface finishes.

The molds, also known as dies, are made from hardened steel and can be reused thousands of times, which makes the process very efficient for high- volume production. You can choose from several metals, including aluminum, zinc, and magnesium, depending on the specific performance and weight needs of your part. Die casting is especially useful when you’re working on components for industries like automotive, electronics, appliances, and industrial equipment that require strength, durability, and precision.

What are the advantages of Die Casting?

Die casting gives you the ability to produce high-strength, complex metal parts with great surface finishes, while keeping production efficient and cost-effective for larger quantities. It’s one of the best ways to manufacture parts that need both performance and precision.

Here are some of the main benefits you’ll enjoy:

● Excellent dimensional accuracy

● Ideal for large orders

● Smooth surface finishing

● Complex shapes and geometries

● High material utilization

● Thin-walled components

When do you need Die Casting?

You need die casting when you want to produce a high volume of metal parts that are consistent in quality, complex in design, and durable in performance. This process is especially useful when your project demands tight tolerances, a smooth finish, and the ability to repeat the same geometry thousands of times.

If you're working in industries like automotive, aerospace, consumer electronics, or industrial machinery, die casting can save you time and money. It’s also the right choice when you’re looking to reduce the number of separate components by combining features into a single, integrated part. If your part needs to be lightweight yet strong, such as with aluminum or magnésio, die casting is likely the ideal method to consider.