If you build or work on cars, you know how important metal parts are. Most of those parts come from flat sheets of metal that are cut, bent, and joined together.

In this guide, I’ll explain what automotive sheet metal fabrication is, how it’s done, and why it matters.

Basics of Sheet Metal Fabrication

You start by picking the right metal based on what you need, such as strength, light weight, or rust resistance.

Then, you cut, bend, and shape the metal. You can use tools like lasers or waterjets for cutting. Bending helps you form it without changing the amount of metal.

Next, you join the parts using welding, rivets, or glue, depending on how strong and neat it needs to be.

Last, you finish it with paint, powder, or planting to make it look better and last longer.

Sheet Metal Fabrication in the Automotive Industry

Cars started with wooden chassis, similar to horse-drawn carriages, but wood couldn’t bend well. The brief history of metal fabrication and its use in automobiles changed when Ford used steel for the 1908 Model T, and Dodge built the first all-steel car body in 1914. This made cars safer and stronger. By the 1970s, aluminum was used for lighter, more fuel-efficient parts.

Today, you still see fabrico de metais everywhere in automotive manufacturing. Sheet metal is used for doors, fenders, and hoods because it’s strong and safe. You also rely on metal parts for engine brackets and mounts, which must be made exactly right to keep the car working well.

Thanks to new technologies like hydroforming, car makers can now shape metal into complex designs, helping build cars that are sleek, fast, and efficient.

Types of Sheet Metals Used in Automotive Fabrication

Here are some common metals you’ll use in automotive fabrication:

Alumínio

Aluminum is lightweight and resistant to corrosion. It’s one of the most common metals for car parts because it has a high strength-to-weight ratio. This means your car parts will be lighter, which helps reduce fuel use and lowers the carbon footprint. Even with less weight, the parts will still be strong. You’ll find aluminum in parts like hoods, doors, and fenders.

Aço inoxidável

Aço inoxidável is strong, durable, and looks good. It’s often used for parts like exhaust pipes, body panels, and seat frames.

Cold Rolled Steel

Cold-rolled steel is strong and accurate in size and finish. You’ll use it for parts like door panels, frame rails, brackets, and interior components, such as seat frames and dashboard structures.

Chapa galvanizada

Galvanized steel is coated with zinc to resist corrosion. It’s perfect for car parts like body panels and chassis.

Titânio

Titanium is a strong, corrosion-resistant metal that works well for parts dealing with heavy loads or harsh conditions. It’s also heat-resistant, that is why it is ideal for parts exposed to high temperatures. However, it’s expensive, so you’ll mostly use it for high-end custom parts.

Cobre

Copper is great for electrical parts because it has excellent electrical conductivity. It’s also good for parts that need to handle heat, like radiators and heat exchangers.

Magnésio

Magnesium is a lightweight metal with a great strength-to-weight ratio, just like aluminum. It also has good thermal conductivity. You’ll use magnesium in parts like steering wheels, instrument panels, and transmission cases.

Sheet Metal Fabrication Techniques for Automotive Parts

Sheet metal fabrication includes different methods to create parts with unique shapes. Some of these methods are used during the design of car sheet metal parts.

Sheet Metal Cutting Techniques

These methods help cut sheet metal into smaller parts of various sizes:

Corte a laser

Laser cutting is often used for car parts because it’s very precise. A focused laser beam melts and vaporizes the sheet metal to create a clean cut.

When CNC technology is used, laser cutting becomes even more accurate. This makes it ideal for car parts with complex designs. It’s also compatible with many materials and is commonly used for parts like body panels and engine components.

Corte a plasma

Corte a plasma uses high-velocity ionized gas (plasma) to melt and blow away the metal, cutting the sheet. It’s great for cutting thick metal sheets, so it’s often used for making car frames.

Shearing

Shearing uses a shearer, which applies a downward force to cut the sheet metal.

Unlike laser and plasma cutting, shearing is less precise, so it’s best for car parts that don’t need tight measurements. Examples include brackets and supports.

Sheet Metal Forming Techniques

Forming techniques like bending and stamping help you shape materials into parts.

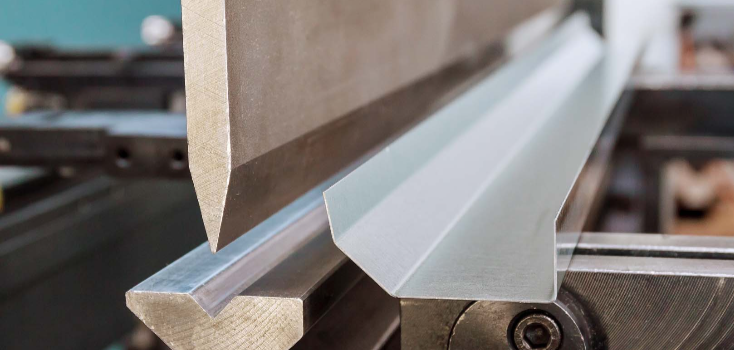

Dobragem

Bending is a common technique where a press brake machine is used to bend sheet metal into angles and curves. The machine applies force at specific points to form the desired shape. Bending is great for making auto parts like brackets, frames, and doors with complex designs.

Estampagem

Stamping or pressing shapes sheet metal by pressing it into a die. There are different types of stamping, like blanking, punching, and embossing. Stamping is best for making high-volume parts like body panels and brackets.

Sheet Metal Joining Techniques

In the automotive industry, joining techniques like welding and riveting are used to combine sheet metal parts.

Soldadura

Welding uses heat to join two or more pieces of metal. Common types of welding are spot welding, MIG weldinge Soldadura TIG. Welding is ideal for joining similar materials and creating strong, durable parts like car chassis, frames, and body panels. It’s fast and efficient.

Riveting

Riveting joins two different metals by creating holes in both pieces, inserting a rivet, and deforming the rivet to hold the parts together. This cold joining process creates a strong, permanent bond. Riveting is great for joining parts made of different materials that need strength and durability.

Applications of Sheet Metal Fabrication Parts in the Automotive Industry

Sheet metal fabrication is used in three main ways:

Car Bodies and Frames

Sheet metal fabrication is perfect for making car bodies and frames. These parts need to be strong and precise, no matter the design or material. With sheet metal techniques, you can use materials like high-strength steel and aluminum alloys to create durable, lightweight car bodies and frames.

Car Customization

You can use sheet metal fabrication to make customized parts for different cars. This helps cater to different customer preferences. Techniques like welding and riveting allow manufacturers to create custom body kits, exhaust systems, grille guards, fender flares, and even chassis.

Vintage Car Restoration

Sheet metal fabrication can also be used to restore classic cars to their original condition. It can help repair or replace damaged parts, replace discontinued parts, and create new interior components to enhance the car’s performance and look.

Benefits of Sheet Metal Fabrication for the Automotive Industry

Sheet metal fabrication offers many benefits for both manufacturers and consumers, and some of these benefits are discussed below.

Lightweight Cars for Better Fuel Efficiency

Sheet metal fabrication uses lightweight metals, which is a major benefit for the car industry. Lighter car parts mean the car needs less energy to move, which reduces fuel use and lowers the carbon footprint. Metals like aluminum and high-strength steel alloys are lightweight but strong, so car parts can be thinner and lighter without losing strength.

Durability and Longer Life of Parts

Using sheet metal fabrication makes car parts last longer and perform better. It helps cars handle rough conditions, like road debris, and improves crash safety by protecting passengers during collisions. Metals like steel and aluminum are strong, resistant to wear and tear, and can resist rust, so parts stay in good condition for a long time.

Customization and Design Flexibility

Sheet metal fabrication is great for making custom car parts. It allows car manufacturers to create complex shapes that improve aerodynamics, look better, and meet specific needs. With CAD, parts can be made with high precision and accuracy, ensuring a better fit and alignment.

Cost-Effective Production

Sheet metal fabrication is a cost-effective way to produce car parts. It allows manufacturers to make large quantities of high-quality parts at low costs. Using CAD technology improves precision and consistency, reduces human error, and cuts down on waste.

Since sheet metal is easy to get and costs less, manufacturers can lower production costs and make cars more affordable. Maintenance costs are also lower because sheet metal parts are easier to repair and replace.

Challenges and Tips When Choosing Automotive Sheet Metal Fabrication

Here are some challenges you might face with automotive sheet metal fabrication and tips to help:

Maintaining Precision

It’s important to keep parts precise. Even a small mistake can make a part defective, which can cause problems during assembly. To improve precision, follow industry standards and use CNC systems for processes like welding, laser cutting, and plasma cutting.

Ensuring Quality Materials

Using good-quality materials is crucial. Sheet metal should not have defects like cracks, holes, or bends, as these can weaken the part. To make sure you get good materials, choose a reliable supplier.

Managing Manufacturing Tolerances

Some parts need very tight measurements, which can increase production costs. To meet these standards, consider outsourcing to a trusted sheet metal fabrication service with the right equipment. This helps you avoid high upfront costs while still getting the parts you need.

High Quality Sheet Metal Fabrication with DEK

Em DEK, we use advanced technology, a wide range of high-quality materials, and fast turnaround times to provide solutions that fit the specific needs of the automotive industry. So if you need a partner for your metal fabrication, choose DEK for a smooth, top-quality experience.

For more information, to talk about your project, or to see how our sheet metal fabrication services can improve your automotive manufacturing, feel free to contact us. We look forward to working with you and helping you reach your manufacturing goals. Get a free quote today!

Conclusão

Precision, quality, and efficiency are key in the automotive industry, and sheet metal fabrication can help you achieve them. This article explains the process so you can decide if it’s the right fit for your needs.

FAQs

What is the thickness of automotive sheet metal?

Automotive sheet metal is usually between 18 and 22 gauge thick. The most common thickness is 20 gauge. A lower gauge number means the metal is thicker.

How does CAD improve automotive sheet metal fabrication?

CAD technology makes sheet metal fabrication more precise, faster, and cost-effective. It helps create accurate 3D models, reduces material waste, speeds up production, and allows quick design changes. CAD also improves team collaboration and ensures high-quality parts.

What are automotive sheet metal fabrication tools?

Automotive sheet metal fabrication tools include machines like laser cutters, CNC presses, stamping machines, shears, and welding equipment. These tools help shape, cut, and join metal to create parts for vehicles.

Is custom automotive sheet metal fabrication expensive?

Custom automotive sheet metal fabrication can be expensive because it requires specialized tools, skilled labor, and precise design work. The cost depends on factors like the complexity of the part, the materials used, and production volume.