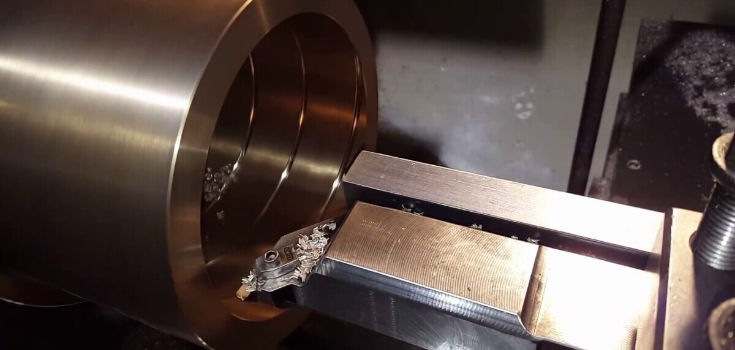

Grooving is an important machining process used to create narrow cuts or channels in a workpiece. It is commonly done on CNC machines using specialized grooving tools.

In this blog, we’ll go over the three main types of grooving tools and how to use them in CNC machining.

What is Grooving?

Grooving (also called recessing) is a cutting process done on a CNC lathe machine. It creates narrow channels or recesses on a workpiece to help parts fit together or make space for seals, O-rings, and similar components.

Different cutting tools are used based on the material. These tools vary in shape, size, and hardness, which affects the groove’s shape. Grooving requires precision to ensure the right depth and width without damaging the material.

Types Of Grooving Tools

Most grooving tools are made from cemented carbide or high-speed steel (HSS). They help create grooves on different parts of a workpiece. Below are the main types of grooving tools.

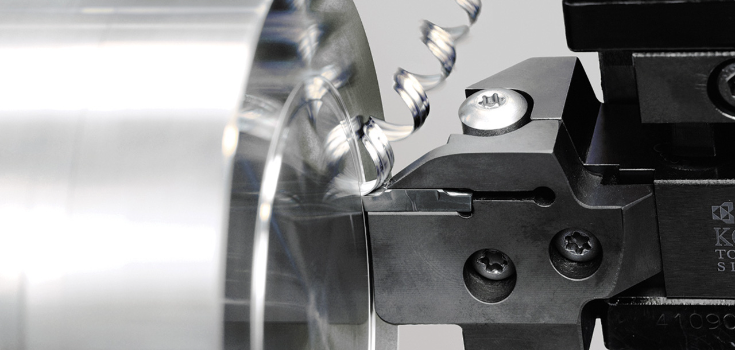

Face Grooving Tools

You use a grooving tool to cut grooves on the face of a material. This tool is useful for reaching hard-to-access areas.

For the best results, position the tip slightly above the center line, and make sure the tool’s radius matches the groove. Always remove chips to prevent breakage.

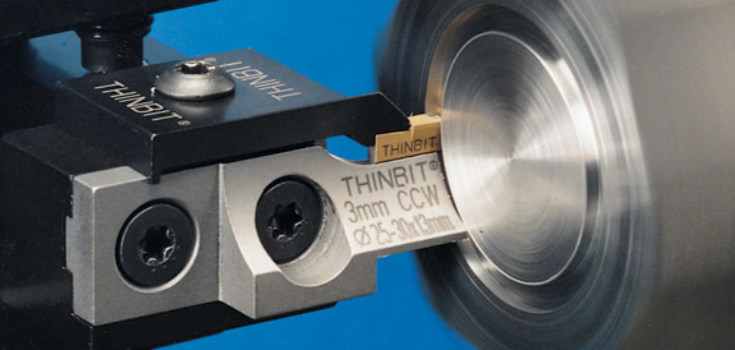

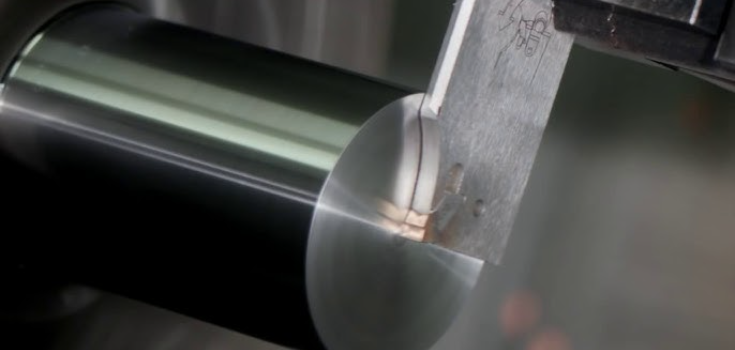

Outer Diameter Grooving Tools

Outer diameter grooving tools create grooves on the outer surface of a part. These grooves can help form external features like gears. For better results, place the tool’s tip just below the center line. Some tools have coolant holes to reduce wear and extend their life.

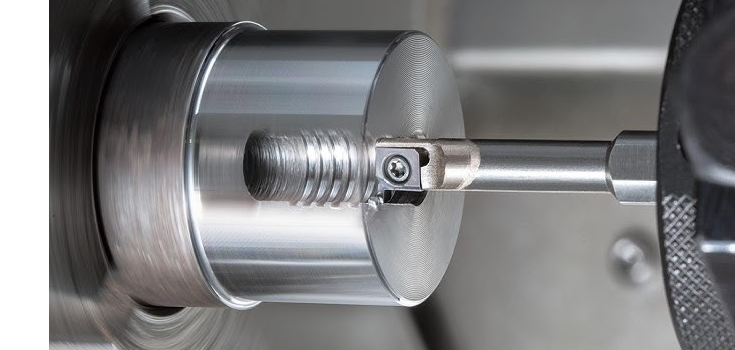

Inner Diameter Grooving Tools

You use an inner diameter grooving tool to cut grooves inside pipes, tubes, or other hollow parts. These grooves help hold seals in place, improving function. To avoid tool breakage, keep the upper part of the tool above the center line.

How To Grooving with CNC Machines?

Follow these five steps for a successful grooving operation on a Máquina CNC:

1. Plan and Design the Groove

First, decide where you want the groove and how big it should be. Use CAD (Computer-Aided Design) software to create a model of the groove on your workpiece.

2. Save the Design

Once your design is ready, save it in a file format that your CNC machine can read. The most common formats are IGES and STEP, but STEP is usually the best choice.

3. Set up the CNC Machine

Now, get your CNC machine ready. Choose the right tool for the grooving process and attach it securely. Then, place and fix the workpiece correctly to avoid movement during cutting.

4. Run the Grooving Operation

Start the CNC machine and let it do the work. Since the program controls the cutting process, you just need to monitor it to ensure everything runs smoothly. The machine will follow the set feed rate and rotation speed to create precise grooves.

5. Check the Quality

After cutting, inspect the grooves to make sure they are accurate and smooth. Check the dimensions and surface quality to ensure the final result meets your requirements.

Types of Grooving Methods

Below, we discuss the different types of grooving methods.

Face Grooving

In face grooving, the grooves run along the axial direction of the workpiece. A special face grooving tool is used for this type of cutting.

Internal Grooving

This method creates grooves inside a hollow surface, like the inside of a pipe.

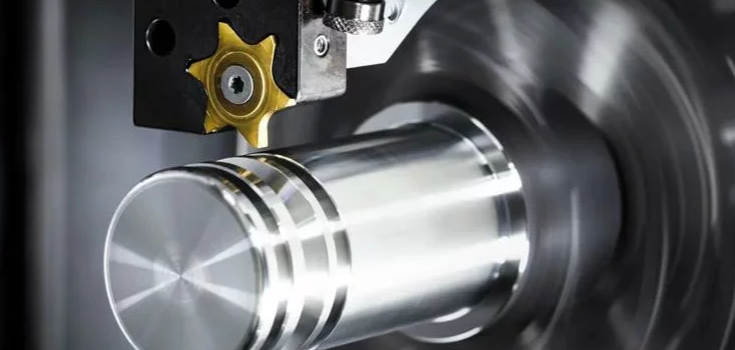

External Grooving

External grooving cuts grooves on the outside of the workpiece. There are three types of external grooving:

Single-cut Grooving: Makes a single groove on the outer surface,

Multiple Grooving: Create several deep grooves on the outer diameter.

Ramping: Uses both radial and axial movements, one after the other, to shape the groove.

Contour Grooving

If you need to create grooves with specific shapes or patterns, you use contour grooving. This method works well for non-circular or non-linear paths. However, setting up the program for this type of machining can be more difficult.

Considerations When Choosing a Grooving Tool

When picking a grooving tool, you need to consider a few important things. Here’s a simple breakdown:

- Different grooving tools are made for different jobs. A tool for cutting grooves inside a material (internal grooving) won’t work for grooves on the outside (external grooving).

- Not all grooving tools work with every material. Some are better for metal, while others are made for plastic or wood.

- The depth and width of the groove matter. Each tool is designed to cut grooves of a certain size.

- Your machine has limits on how fast it can cut and how much material it can remove at a time.

- The tool needs to be held securely in place to work safely and correctly. Check that your machine’s tool holder can properly hold the grooving tool you choose.

Common Problems and Solutions in Grooving Machining

Grooving machining is useful, but it comes with some challenges. Here’s how you can handle them:

Acabamento superficial deficiente

If your groove has a rough surface, it’s often because the cutting speed or feed rate isn’t right. To fix this, use the recommended cutting speed. Start with a slow feed rate and gradually increase it until you get a smooth finish.

Dimensional Accuracy Issues

Getting the exact size and shape of a groove can be difficult. Some measuring tools aren’t precise enough. Steel rulers work for rough measurements, but if you need high accuracy, use Vernier calipers.

Cutting Tool Breakage

Your tool might break if it doesn’t get enough cooling. Always use a cooling fluid when machining. It helps keep the tool and workpiece cool, preventing damage.

Tool Chatter or Vibration

Vibration can make your work unsafe and reduce quality. To avoid this, use strong tool holders and ferramentas de corte. Also, try to keep the tool overhang as short as possible.

How to Improve Grooving Machining?

The quality of your grooves depends on both your machine and your process. Here are some ways to make grooving machine parts more efficient:

Checking and Measuring Your Work

Use the right measuring tools based on how precise your groove needs to be. If you don’t need high accuracy, use steel rulers or calipers. For more precise grooves, use Vernier calipers, plug gauges, or micrometers.

Choosing the Right Grooving Tool

The tool you use directly affects the final look of the groove. High-speed steel CNC cutting tools last longer and resist wear. For narrow grooves, use a lathe tool with a width that matches the groove size to get better results.

Adjusting Feed Rate and Cutting Speed

How fast you feed the tool and how quickly it cuts affect the machining time and surface finish. Start with a slow feed rate and gradually increase it to improve chip removal. Always use the recommended cutting speed to make your tool last longer.

Using Cutting Fluid

Cutting fluids like oil, paste, or aerosols help keep the workpiece cool and lubricated. This reduces friction, improves cutting, and makes it easier to remove chips.

Improved Grooving with DEK

Em DEK, we provide high-quality grooving tools and precision CNC machining services to help you achieve perfect cuts every time.

We always choose the right tool for the job, correctly adjust the cutting speed and feed rate, and use proper cooling to prevent tool damage. With careful planning and setup, we can improve grooving operations and achieve better machining results.

Contact us today to get a free quote!

Conclusão

Grooving is an essential machining process that requires the right tools and techniques for the best results. By understanding the different types of grooving tools and methods, you can create precise and high-quality grooves in your workpieces.

FAQs

What is the difference between a groove and a slot?

A slot is a long, straight hole with rounded edges. It is usually cut in a way that is straight across a cylinder. A groove is similar but shaped like a ring around the outside or inside of a cylinder.

Do grooving tools need a coating?

Grooving tools are usually made of metal, so manufacturers often coat them to prevent rust and make them last longer. However, coating is not required.

What material is best for grooving tools?

Since grooving tools cut through hard materials, they need to be strong. Diamond is the best choice because it is very hard and handles heat well, but it is expensive. Many manufacturers use cheaper options like carbide or steel.