Brass finishing is the final step that gives your machined parts their look and feel, and you have many options. Some finishes are best for decoration, while others are made to handle tough use.

In this blog, you’ll learn about the 10 types of brass finishing so you can have an idea which one to choose for your project.

What is Brass Finishing?

Brass finishing is a process where you treat the surface of brass to make it better, like brass with gold finishing or brass with palladium finishing. You can use different methods to make it look nicer and last longer.

These treatments help protect the brass from rust and wear. Some finishes can also improve how the part works in certain jobs.

Common Types of Brass Finishing Techniques for Custom Parts

Here are the most commonly used types of brass finishing:

Electroplating Brass

Galvanoplastia is a way to coat the surface of a brass part using electricity and special chemical solutions. To start, you need to clean the brass part very well. Make sure you remove all the grease, dirt, rust, oil, or any old coatings.

After that, you should polish the surface and get rid of any small scratches or marks. Once the surface is smooth and clean, you dip the part into a chemical bath that contains zinc cyanide, copper cyanide, and free cyanide. Be careful during this step because these chemicals are very toxic and must be handled safely.

Vantagens

- This finish helps protect the part from rust and wear.

- It makes the part stronger and lasts longer.

- It also gives the part a smooth and shiny look, which can be great for decoration.

- Electroplated brass can handle high heat, so you can use it in hot environments.

Desvantagens

- The chemicals used are dangerous and bad for the environment.

- You need special equipment, which is expensive and takes time to use.

- If the coating is too thin, it may not stick well or last long.

Where You Can Use It

- Hardware parts

- Cars and trucks

- Interior design projects

- Buildings and architecture

- Bathrooms

- Artwork

- Mobiliário

- lighting

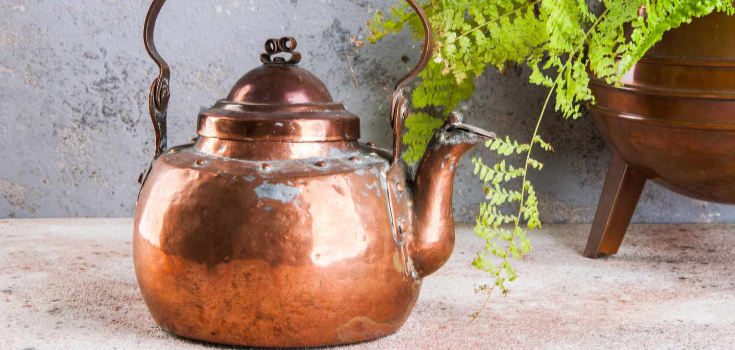

Antique Brass Finish

An antique brass finish is a way to make your brass parts look old and classic, with a warm and rich tone. To start, you need to clean the brass well and remove any dirt or leftover material. After that, dip the part into a strong cleaning solution that removes some of the zinc from the surface. This helps prepare the part for the next step.

Then, soak the part in a mix of arsenic and sulfur. This darkens the surface and gives it that aged look. Finally, apply a clear coating, called lacquer, to protect the part from rust and help it last longer.

Vantagens

- This finish gives the part a beautiful, timeless look.

- It makes the part stronger and helps it last longer.

- The surface doesn’t get scratched or marked easily, so it’s easy to keep clean.

- You can use this finish in lots of places and for many different types of products.

- It helps save money over time because your parts won’t wear out as quickly.

Desvantagens

- Most antique finishes look similar, so you don’t get many style options.

- Strong chemicals or cleaners can still damage the surface.

- Making brass look aged with chemicals costs more than letting it age naturally.

Where You Can Use It

- Building and architectural features

- Artigos decorativos

- Home decor

- Cars and trucks

- Art and collectibles

- Jóias

Satin Brass Finish

A satin brass finish gives your brass parts a smooth, non-shiny look with a soft, modern style. First, you use brushes or abrasive belts with different grain sizes to gently polish the surface.

This removes small imperfections and marks, especially those caused by laser cutting. It also smooths the surface and lowers the chances of bacteria growing. The finish helps make the part more durable and gives it a clean, even appearance without a strong reflection.

Vantagens

- The surface looks elegant and modern with less shine.

- The finish is even and smooth across the whole part.

- It helps protect the part from rust and tarnish.

- It’s easy to clean; just wipe it down.

- Fewer surface flaws mean fewer spots where germs or dirt can collect.

Desvantagens

- The surface shows fingerprints and smudges easily, so it needs frequent cleaning.

- It can scratch more easily, and scratches are more noticeable.

- There are not many color or design choices available.

Where You Can Use It

- Building and architectural materials

- Decorative pieces

- Mobiliário

- Peças para automóveis

- Peças eléctricas

- Industrial tools and machines

Brushed Brass Finish

A brushed brass finish gives your parts a soft texture with fine lines that you can see and feel. To start, you polish the brass to make it smooth and shiny. Then, you brush it using special tools to create a matte, brushed look. Finally, you add a clear coat, called lacquer, to protect the part from rust and wear.

Vantagens

- The finish has a clean, textured look with fine line patterns.

- It makes the part stronger and protects it from rust and tarnish.

- The texture helps hide fingerprints and small marks.

- It lowers the chance of germs or dirt building up, so it’s more hygienic.

Desvantagens

- Scratches are easy to see on this type of finish.

- You have fewer options for colors and styles.

Where You Can Use It

- Electrical parts and electronics

- Industrial equipment

- Cars and automotive parts

- Decorative and architectural pieces

- Furniture and home decor

Powder Coating Brass Finish

Revestimento em pó is a way to give your brass parts a strong, colorful, and protective finish. First, you need to clean the brass thoroughly to remove any dirt, oil, or debris. Then, you prepare the surface by applying a special self-etching primer or a pretreatment solution. This helps the coating stick better.

After that, you spray dry powder onto the brass using an electrostatic gun. The brass part is charged with electricity, which helps the powder cling to it. Then, you heat the part so the powder melts and forms a smooth, solid layer. Once it cools, you check the part to make sure it looks right and has the right finish.

Vantagens

- Makes the brass much stronger and more resistant to scratches, chips, and wear.

- Helps protect the brass from rust and weather damage, making it last longer.

- You can choose from many colors and styles to customize the look.

- Gives a smooth and even finish, even on detailed or odd-shaped parts.

- It’s better for the environment because it uses low-toxicity materials and creates little waste.

- Works well for mass production since it’s efficient and clean.

Desvantagens

- The coating adds thickness to the part, so you might need to adjust the design.

- It blocks electrical flow, so it’s not good for parts that need to conduct electricity.

- Masking certain areas without affecting the part’s function can be difficult.

- If you find a flaw, you often have to strip the part and start over.

- Preparing the surface needs special tools and chemicals, which adds to the cost.

Where You Can Use It

- Building and decorative parts

- Furniture and home items

- Peças para automóveis

- Electronics and electrical components

- Industrial machines and tools

Brass PVD (Physical Vapor Deposition) Finish

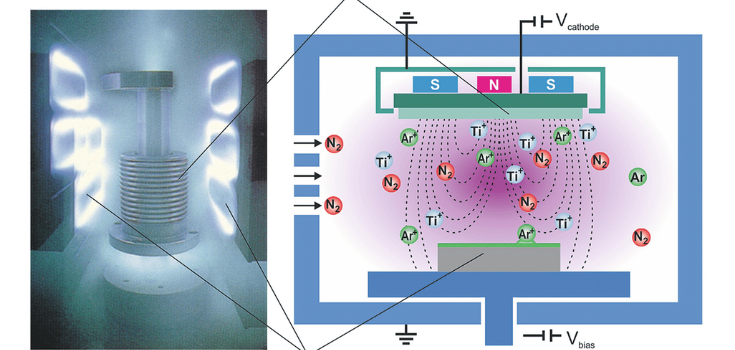

PVD coating is a way to cover your brass parts with a very thin layer of protective metal, like titanium alloy, without changing the part’s shape or look. It keeps the original brass color and gives it a clean, shiny finish. The coating process is simple but requires special machines.

Vantagens

- Adds a strong barrier that protects the brass from rust and weather damage.

- Makes the surface more scratch-resistant, so it looks new for longer.

- It’s easy to clean and take care of.

- Keeps the original color and style of your brass part.

- Gives you high-quality results with a consistent look every time.

Desvantagens

- Needs special equipment, which makes the process more expensive.

Where You Can Use It

- Artigos decorativos

- Weather tools and equipment

- Building hardware and fixtures

- Peças para automóveis

- Jóias

- Optical devices

Polished Brass Finish

Polished brass gives your parts a shiny, mirror-like look. To get this finish, you first need to clean the brass carefully, removing all dirt, dust, and grease. Once it’s clean, you sand the surface. Start with rough sandpaper and slowly switch to finer sandpaper to make the surface smooth and shiny. After polishing, you apply a clear lacquer to give it a glossy finish and help protect it.

Vantagens

- Has a bright and shiny look that makes your brass parts stand out.

- Helps protect the brass from rust, so it works well both indoors and outdoors.

- The mirror-like shine makes it great for showing off detailed designs.

Desvantagens

- Needs regular cleaning because it easily shows fingerprints and dirt.

- The clear coating can wear off over time and will need to be reapplied.

Where You Can Use It

- Hardware like handles and hinges

- Interior design pieces

- Building and architectural features

- Elevators and door panels

- Car parts and trims

- Furniture and lighting

- Bathroom fixtures

- Art and decorations

Burnished Brass Finish

A burnished brass finish gives your parts a soft, aged look. First, you smooth the surface by filling in tiny gaps. Then, you harden the brass to make it stronger. After that, you remove small flaws like dents or rough spots by compressing the surface. This also helps reduce the chance of corrosion.

Vantagens

- Gives a soft, vintage look that’s great for classic or antique-style items.

- Creates a low-shine finish that doesn’t reflect as much light, which might suit your design better.

- The hardening step makes the part more durable and less likely to crack.

- Smoothing out flaws helps protect the part from rust and damage.

Desvantagens

- The soft, dull look may not stand out or work for every type of design.

- The thin surface treatment can wear off over time, and the brass will darken.

Where You Can Use It

- Handmade and custom items

- Trophies and award pieces

- Decorative and antique-style items

Waxed Brass Finish

Waxing brass helps protect its shiny surface and keeps it looking clean and polished. First, you clean and dry the brass pieces completely. Then, apply a thin layer of wax using a soft cloth or applicator. Once the wax sets, buff the piece to bring out a soft, lustrous shine.

Vantagens

- Keeps the brass looking shiny and prevents stains, fingerprints, and dust.

- Adds a protective layer that slows down rust and corrosion.

- Easy to clean and maintain with simple wiping.

Desvantagens

- Needs regular reapplication, which can be time-consuming.

- Doesn’t completely stop tarnishing, just slows it down.

- Not suitable for every design, especially those with complex shapes or textures.

Where You Can Use It

- Home decor items

- Brass hardware

- Instrumentos musicais

- Jewelry and small accessories

Patinated Brass Finish

A patinated brass finish gives your parts an aged, weathered look by creating a thin oxide layer on the surface. This can happen naturally over time, or you can force the patina using chemicals.

One method uses brass black after cleaning the brass. Another method involves placing the brass in a mix of ammonia and salt for a few hours. You can also use steel wool and baking soda to adjust the finish.

Vantagens

- The dark, antique look adds unique character and style.

- The oxidized layer helps protect against rust and corrosion.

Desvantagens

- If the chemicals are not used correctly, they can damage the brass.

- The final look can vary from piece to piece, so it is hard to repeat for mass production.

- The outcome is hard to control and may not turn out exactly as expected.

Where You Can Use It

- Home decor pieces

- Building and architectural accents

- Artistic and handmade designs

- Restoration of antique brass items

DEK’s High-Quality Brass Finishing Services

A good brass finish can make your products look and feel much better. At DEK, we have a special area just for handling finishing jobs. Our team of surface experts is here to help you choose the right finish for your needs.

Just send us an email with what you’re looking for, and our technical team will take care of the rest.

Conclusão

There are many ways to finish custom brass parts. It’s a good idea for you to learn about each type and where it’s used. This will help you choose the finish that works best for your part.