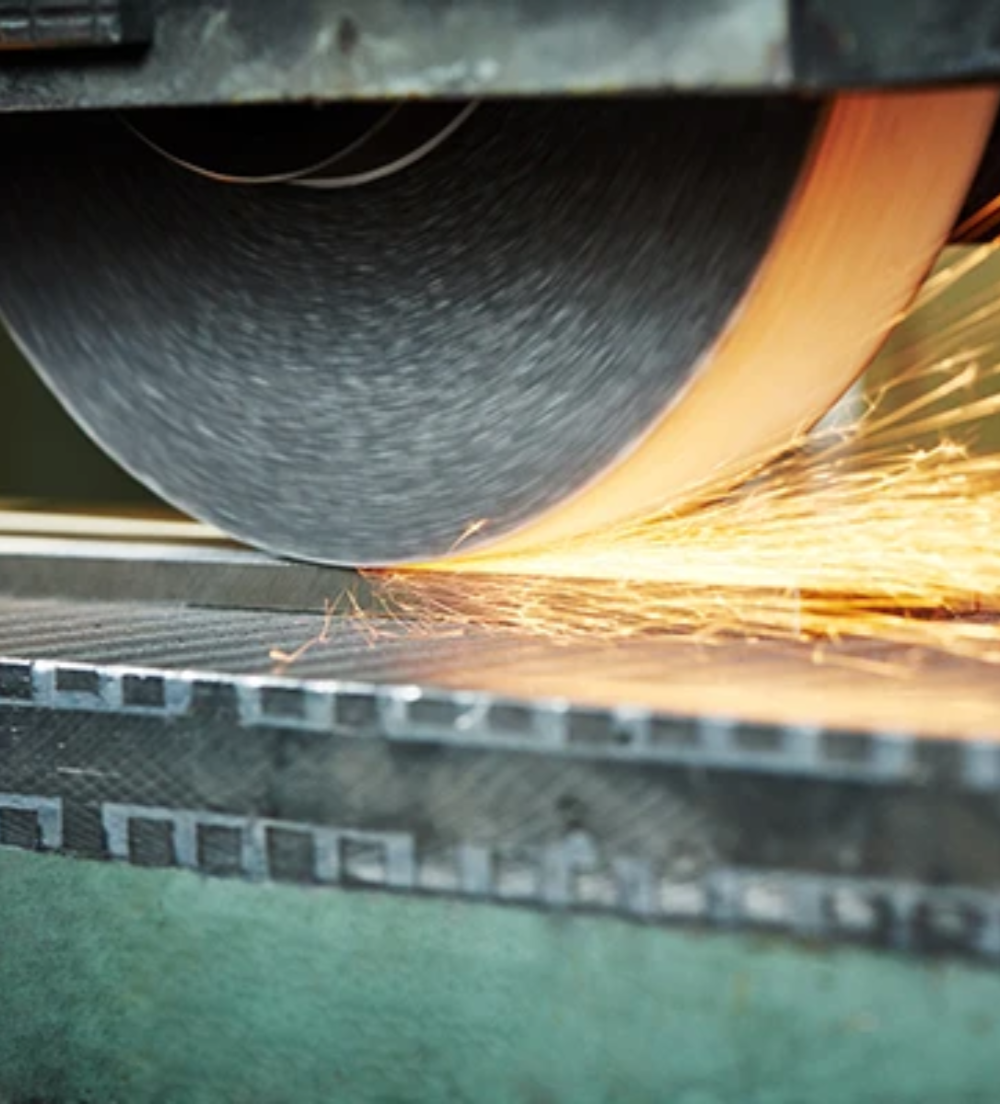

Surface Grinding Service

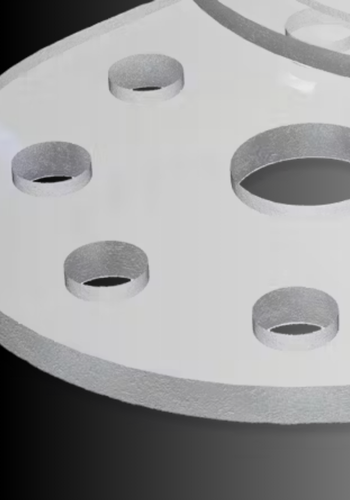

Surface grinding service smooths and flattens metal or hard materials with high precision, improving surface finish and ensuring exact thickness, flatness, and parallelism.

DEK offers high-precision surface grinding services with tight tolerances and smooth finishes. Unlike others, we use advanced equipment and strict quality control to ensure consistent accuracy, fast turnaround, and competitive pricing, making it a reliable choice for both simple and complex grinding projects.

Einführung

Expert Flachschleifen Service Solutions

DEK delivers reliable surface grinding solutions with state-of-the-art machinery, achieving accurate flatness, fine finishes, and consistent quality for custom metal components across various industries.

With a focus on accuracy and finish quality, DEK provides surface grinding services for a broad range of metals and hard-to-machine materials. Our facility is equipped with high-performance surface grinders, including CNC-controlled machines that ensure consistent accuracy, even on complex or tight-tolerance parts. We support both low and high-volume production runs and can work with various materials such as steel, stainless steel, aluminum, and more. Whether for tooling plates, precision components, or mold parts, DEK’s surface grinding service guarantees consistent surface finish and dimensional control.

Apart from flat surface grinding, we also offer custom grinding solutions tailored to your project needs. Our strict inspection process ensures every part meets your exact specifications, and we also provide additional services like polishing, coating, or further machining if required.

- High-precision grinding machines

- Tight tolerance capabilities

- Wide range of materials supported

- Schnelle Durchlaufzeiten

- Custom surface finish options

- Prototype and full production runs

Materialien for Surface Grinding Service

Metalle

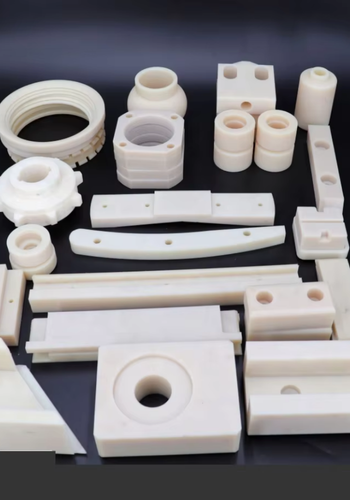

Kunststoffe

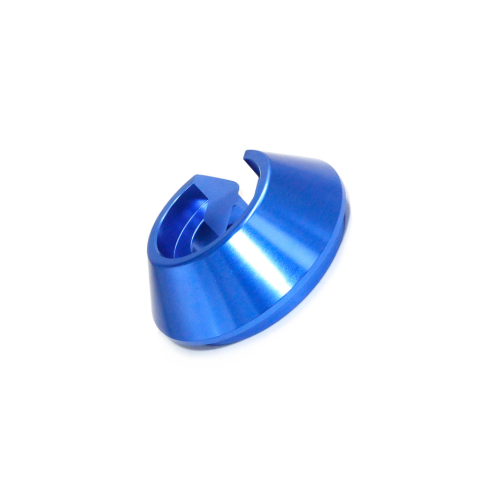

Aluminium

Aluminum alloys are valued for their lightweight, corrosion resistance, and excellent machinability, making them essential in aerospace, automotive, and structural industries. High-grade alloys such as 6061 and 7075 require precise surface finishes to maintain strength and functionality.

DEK’s surface grinding service delivers superior flatness and smooth finishes, ensuring parts meet strict dimensional tolerances. Our advanced grinding technology and expertise optimize aluminum components for high performance in demanding applications while preserving material integrity and quality.

Legierung

AL6061, AL6063, AL5083, AL5052, usw.

Messing

Brass is a copper-zinc alloy valued for its machinability, corrosion resistance, and aesthetic appeal. Commonly used in fittings, precision instruments, decorative hardware, and electrical parts, it offers low friction and durability. Its ease of shaping makes it ideal for detailed, high-precision components.

Our surface grinding service delivers smooth, flat finishes with tight tolerances, preserving both the structural integrity and appearance of brass parts. Our process enhances performance and aesthetics for demanding mechanical and decorative applications across various industries.

Legierung

Messing 260, C360, Cz121, usw.

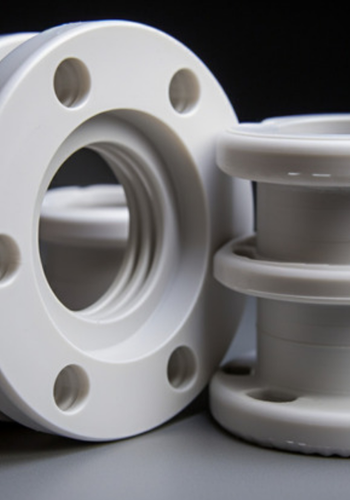

Gusseisen

Cast iron is a durable material known for excellent compressive strength and vibration damping, commonly used in machinery bases and automotive parts. Specialized grades like gray and ductile cast iron require precision surface grinding to achieve smooth, flat surfaces for proper component fit and function.

We can handle various cast iron grades with accuracy and care, delivering parts that meet tight specifications and enhance operational performance in industrial applications.

Legierung

Gray Cast Iron, Ductile Cast Iron, White Cast Iron

Kupfer

Copper is a soft, highly conductive metal used extensively in electrical, thermal, and industrial applications. Due to its ductility, it requires precise control during surface grinding to avoid deformation and ensure a smooth, flat finish.

DEK’s surface grinding service is tailored for copper, delivering tight tolerances and clean surfaces without compromising conductivity or material integrity. Our process ensures copper components meet performance standards in demanding applications where surface quality and dimensional accuracy are critical.

Legierung

Kupfer C101, C110, usw.

Rostfreier Stahl

Stainless steel offers excellent corrosion resistance, strength, and an attractive finish, making it ideal for medical, food processing, and construction industries. Common grades like 304 and 316 require surface grinding to achieve precise flatness and smoothness for durability and functional performance.

DEK utilizes high-precision equipment and skilled operators to deliver consistently accurate, polished parts that meet strict industry standards and client specifications.

Legierung

Edelstahl 301, 303, 304, 304L, 316, 316L, usw.

Titan

Titanium is prized for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, making it essential in aerospace and medical implants. Surface grinding titanium parts demands careful control to avoid heat damage and maintain material integrity.

We use precise techniques and state-of-the-art equipment to deliver perfectly flat, smooth titanium components with tight tolerances, supporting high-performance applications requiring both strength and precision.

Legierung

Titan Grad 1, Grad 2, Grad 5, usw.

Werkzeugstahl

Tool steel is a high-hardness material widely used for molds, dies, and cutting tools requiring superior wear resistance. Achieving precise dimensions and flawless surfaces through surface grinding is critical for tool performance and longevity.

DEK’s surface grinding service expertly handles tool steel grades like A2, D2, and O1, using advanced CNC grinders to deliver tight tolerances and smooth finishes, ensuring optimal function and extended tool life in demanding manufacturing processes.

Legierung

Werkzeugstahl A2, A3, D2, S7, usw.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a durable and lightweight thermoplastic known for its impact resistance, rigidity, and excellent dimensional stability. It is widely used in enclosures, housings, automotive parts, and consumer products where strength and formability are important. ABS also offers good machinability and electrical insulation properties, making it suitable for both functional and aesthetic applications.

DEK’s surface grinding service ensures smooth, flat finishes on ABS components, enhancing dimensional accuracy and surface quality. Ground ABS parts are ideal for industries requiring consistent tolerances, clean finishes, and reliable performance in everyday and technical applications.

Delrin

Delrin, also known as acetal, is a high-performance engineering plastic valued for its excellent stiffness, low friction, and dimensional stability. It provides superior wear resistance and excellent machinability, making it perfect for precision parts that require tight tolerances and smooth, consistent finishes.

DEK offers perfectly flat surfaces on Delrin components, enhancing their mechanical strength and ensuring precise assembly fit. With natural resistance to moisture, chemicals, and fatigue, ground Delrin parts are widely used in automotive, industrial, and consumer applications where durability and accuracy are essential.

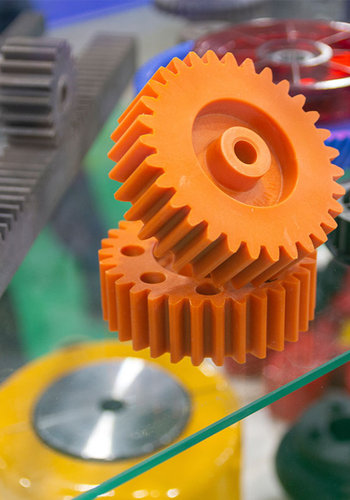

Nylon

Nylon is a strong and versatile thermoplastic known for its toughness, excellent abrasion resistance, and natural self-lubricating properties. It is commonly used in gears, bushings, and structural components that require durability and long-lasting wear resistance.

Our surface grinding service provides precise flatness and smooth finishes on nylon parts, improving their durability and overall performance. Thanks to its ability to absorb impacts and resist various chemicals, ground nylon components are ideal for automotive, electrical, and industrial machinery applications where consistent quality and reliability are crucial.

PEEK

PEEK (Polyether Ether Ketone) is a high-performance engineering thermoplastic known for its exceptional mechanical strength, chemical resistance, and thermal stability. It is widely used in aerospace, medical, and automotive industries for components that demand precision, durability, and reliability under extreme conditions.

DEK’s surface grinding service ensures ultra-flat, smooth finishes on PEEK parts, enhancing dimensional accuracy and functional performance. PEEK’s ability to withstand high temperatures, harsh chemicals, and repeated sterilization makes it ideal for high-precision applications where long-term performance and resistance to wear, heat, and stress are critical to success.

PC

Polycarbonate is a tough, transparent thermoplastic known for its high impact resistance, optical clarity, and excellent heat resistance. It is commonly used in applications such as protective shields, lenses, automotive parts, and electronic housings where durability and transparency are critical. Polycarbonate also offers good dimensional stability and ease of machining.

DEK’s surface grinding service provides precise flatness and smooth finishes on polycarbonate components, enhancing both their functional performance and aesthetic quality. Ground polycarbonate parts are ideal for industries requiring reliable, high-quality components with consistent dimensions and superior surface finishes.

PTFE

PTFE, widely known as Teflon, is a high-performance fluoropolymer prized for its exceptional chemical resistance, very low friction, and excellent tolerance to extreme temperatures. It is commonly used in seals, gaskets, and lining components that must perform in chemically aggressive and high-heat environments.

We provide smooth, flat, and dimensionally accurate PTFE parts, improving sealing efficiency and reducing wear. Its non-stick properties and resistance to contamination make ground PTFE ideal for aerospace, chemical processing, and food applications where cleanliness, precision, and long-term reliability are essential for performance.

PVC

PVC (Polyvinyl Chloride) is a strong, rigid thermoplastic known for its excellent chemical resistance, low moisture absorption, and durability. It is widely used in applications such as piping, valves, electrical insulation, and structural components where corrosion resistance and long-term performance are essential. PVC is also lightweight, easy to machine, and cost-effective.

We deliver precise flatness and smooth finishes on PVC parts, improving fit, sealing surfaces, and overall appearance. Ground PVC components are ideal for chemical processing, electrical, and construction industries that demand consistent quality and dimensional accuracy.

Verschiedene Oberflächenbehandlungen

Eloxieren

Eloxieren ist ein elektrochemisches Verfahren, das die Korrosionsbeständigkeit, die Haltbarkeit und das Aussehen von Metallen, insbesondere von Aluminium, verbessert.

Black Oxide

Get functional and aesthetic benefits in one with Black Oxide surface finishing. It's a matte […]

DLC-Beschichtung

The low friction coefficient of DLC coatings reduces resistance between surfaces, providing durability to components […]

Sofort & Genaue Zitate

Wir verwenden keine automatisierten Online-Kostenvoranschläge, weil sie sehr ungenau sind. Online-Kostenvoranschlagsplattformen stützen sich ausschließlich auf Berechnungen auf der Grundlage von Schnittmengen und festen Koeffizienten und berücksichtigen nicht die tatsächlichen Verarbeitungsnuancen, wie Materialverformung nach der Wärmebehandlung, enge Toleranzanforderungen, Schleifen nach der Wärmebehandlung usw. Folglich können automatische Preisberechnungen zu Ungenauigkeiten führen, die letztlich Ihre Kosten erhöhen.

Aber bei der DEK können Sie beruhigt sein!

Unsere Angebote sind sowohl kosteneffizient als auch präzise, da wir über ein Team professioneller Maschinenbauingenieure verfügen, die jede Zeichnung sorgfältig prüfen. Diese Ingenieure haben mehr als 10 Jahre Erfahrung und verfügen über fundierte Kenntnisse in den Bereichen Programmierung, Maschinenbetrieb, Nachbearbeitung, Materialeigenschaften und mehr. Wir versichern Ihnen, dass Sie innerhalb von 6 Stunden genaue Angebote erhalten.

Unsere Vorteile

2300+ Ingenieure Liebe Arbeit mit uns

Komplexe Geometrien

DEK’s grinding machines can precisely handle flat and angled surfaces, allowing us to grind multiple faces and complex geometries. This ability is critical for producing tooling, dies, and precision components that require perfect surface contact and strict parallelism.

Material Vielseitigkeit

Our surface grinding service supports a wide variety of materials, including hardened steels, stainless steel, aluminum, and carbide, as well as other metals, hard or soft. We customize grinding parameters and select appropriate wheels for each material type.

Kundenspezifische Ausführungen

In addition to grinding, DEK offers various finishing options such as polishing and fine surface treatments. These enhancements improve corrosion resistance, wear durability, and aesthetic appeal to meet specific performance requirements.

Hohe Präzision

DEK’s surface grinding service delivers exceptional accuracy with tolerances as tight as ±0.005 mm. Using advanced CNC surface grinders and experienced technicians, we ensure consistent flatness and thickness for every part.

Kein MOQ

DEK accepts surface grinding orders of any size, from one-off prototypes to large-scale production runs. This flexibility enables customers to test new designs or increase production volumes without minimum quantity restrictions.

Schneller Umschwung

We focus on quick delivery, completing prototype surface grinding projects within just one day and standard orders in 4–7 days. Our modern grinding equipment and streamlined workflow reduce lead times without compromising quality.

Unser Bestellvorgang

RFQ senden

Senden Sie eine Anfrage mit 2D/3D-Zeichnungen und detaillierten Anforderungen per E-Mail oder Online-Formular.

Rezension & Zitat

Unser Ingenieurteam wird jede Zeichnung sorgfältig prüfen und innerhalb von 6 Stunden ein genaues Angebot erstellen.

Bestellung bestätigen

Bestätigen Sie den Kostenvoranschlag, die Einzelheiten und den Lieferplan und unterzeichnen Sie dann den Vertrag.

Produktion

Produktionsprozess organisieren, Programmierung und Bearbeitung starten.

Qualitätskontrolle

Strenge Qualitätskontrolle während der Produktion und der Endkontrolle.

Verpackung und Versand

Verpacken Sie die Teile, bringen Sie Etiketten zur Identifizierung der Teile an, und beginnen Sie mit dem Versand.

RFQ 222 senden

Rezension & Zitat

Bestellung bestätigen

Produktion

QC

Lieferung

FAQ

Flachschleifen FAQs zum Kauf

Genaues Angebot einholen Für Ihre nächsten Projekte

Ganz gleich, ob Ihr Projekt kompliziert oder einfach ist, ob es sich um Metall oder Kunststoff handelt, Sie erhalten innerhalb von 6 Stunden ein genaues Angebot.

Heute ein Angebot einholenVerstehen Flachschleifen

Was ist Flachschleifen?

Surface grinding is a precision machining process used to produce flat, smooth surfaces on a workpiece. It involves the use of a rotating abrasive wheel that removes small amounts of material from the surface through a controlled and consistent process. The workpiece is usually held firmly on a magnetic chuck or other fixture while the grinding wheel moves over it, either in a back-and-forth motion or in a circular pattern, depending on the machine setup. The depth of cut and feed rate are carefully controlled to achieve the desired flatness and surface quality.

This process is commonly performed on materials such as steel, aluminum, and other metals, as well as certain non-metallic materials. Surface grinding machines come in various types, such as horizontal-spindle and vertical-spindle configurations, which determine the orientation of the grinding wheel relative to the workpiece. The primary goal of surface grinding is to create a precise, flat surface by removing material in a uniform manner, often as a final machining step before assembly or finishing.

What are the Advantages of Surface Grinding?

DEK can achieve your desired flatness, parallelism, and squareness specifications by optimizing cutting efficiency with various wheel and material combinations.

Our expertise extends to diverse surface grinding techniques, and we possess the skill to grind any material that falls within our size parameters.

Here are the advantages of surface grinding:

- High surface precision

- Enge Maßtoleranzen

- Smooth surface finish

- Geeignet für harte Materialien

- Consistent results

- Ideal for flat surfaces

- Prepares parts for coating or assembly

- Removes surface imperfections

When do you use Surface Grinding?

Surface grinding is widely used in different industries. In aerospace, it ensures tight tolerances in components like turbine blades. The automotive sector relies on it for precise fits in cylinder heads and transmission parts.

In mold and die making, it is used for accurate and smooth surfaces on molds and dies. Medical device manufacturing uses it for exact dimensions and polished finishes in components like surgical instruments.

Toolrooms apply surface grinding for sharpening cutting tools. It contributes to producing bearings, shafts, and electronic components. The textile industry utilizes it for precision in spindles and gears. Hydraulic and pneumatic components and general machine shop applications benefit from surface grinding for maintaining tight tolerances and optimal functionality. Additionally, surface grinding is used when dealing with hardened materials that are difficult to machine using conventional cutting tools.