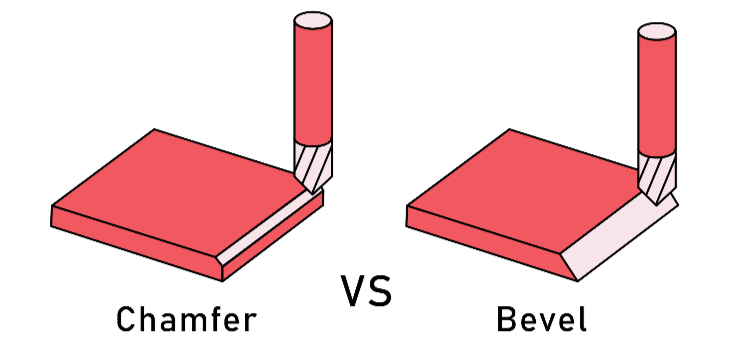

You’ve probably seen angled edges on metal or plastic parts. These are often called chamfers or bevels. Both involve cutting the edge at an angle, and both can make a part look cleaner or work better.

In this blog, we’ll walk you through chamfer vs bevel so you understand their differences. We’ll look at their shape, function, how they’re made, and when you should use one over the other.

Differences Between a Chamfer and a Bevel

Chamfering means cutting off a sharp edge or corner and turning it into a small angled surface. You often see this as a flat edge (like a “C” shape) or a rounded one (like an “R” shape). You usually add chamfers to remove sharp edges, get rid of burrs from machining, or make it easier to fit parts together.

You’ll often find chamfers at the ends of parts in machining, woodworking, furniture making, and even in circuit boards. In design, chamfers are sometimes called rounded corners or R-corners. These can be simple or more complex, depending on what the part needs.

Bevels are also angled edges, but they usually connect two surfaces with a longer slope. You use bevels to avoid sharp corners, make parts safer to handle, and improve how they look or wear over time.

A bevel can be made at almost any angle, except for standard right angles or common chamfer angles like 45°. Some bevels are defined by a specific distance and usually have a sloped surface between flat or curved areas.

Chamfer vs Bevel: Method of Measurement

To measure a bevel or chamfer, you can use tools like an optical comparator or a chamfer gauge.

An optical comparator uses a magnifying lens to zoom in on the sloped edge. This helps you see the surface clearly and measure it more accurately. Some optical comparators are manual, but the digital ones are easier to use and give faster results.

A chamfer gauge has a small flat piece (called an anvil) inside a spring-loaded plunger. You place the anvil on the sloped edge, and it shows the size of the chamfer or bevel. Chamfer gauges can be analog, digital, or even connected to a станок с ЧПУ for automated checks.

While these tools work for both chamfers and bevels, there are some tools made just for one type.

A bevel protractor is made for bevels. It has a round scale with two moving blades. You place one blade on the bevel and the other on the flat surface next to it. This lets you measure the angle very accurately.

A chamfering ruler is made just for chamfers. It’s an L-shaped metal ruler with two connected arms. You place it on both the vertical and horizontal sides of the chamfer to check the lengths. With those numbers, you can figure out the chamfer’s angle and size.

Chamfer vs Bevel: Based on the Connotation

A bevel usually means a sloped or angled edge that connects two flat, parallel surfaces. But making a bevel doesn’t always mean you have to cut the material. Sometimes, a bevel is already formed during the manufacturing process. If the edge ends up slanted between two surfaces, it’s still called a bevel, even if no cutting was done.

A chamfer, on the other hand, always involves cutting. If you create a chamfer, you’re removing material to shape the edge.

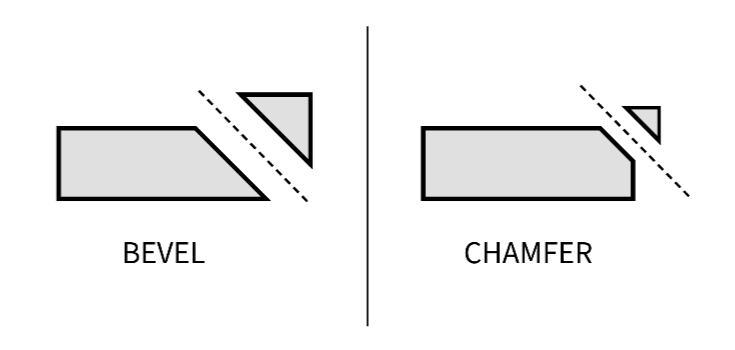

Chamfer vs Bevel: Shape

The main difference between a chamfer and a bevel is their shape and how they connect surfaces. A chamfer is usually cut at a 45-degree angle and connects two edges that meet at a corner.

A bevel can be made at any angle, though 45 degrees is still common. It connects two parallel surfaces instead of adjacent ones, which gives it a different shape.

If you start with a square piece and chamfer all the corners, the inside shape will look like an octagon. But if you bevel all the edges instead, the inside shape will look like a rhombus.

Chamfer vs Bevel: Machining Method

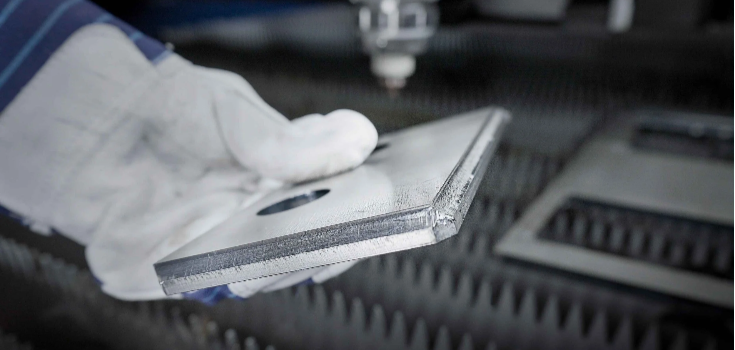

To make a beveled edge, you usually need a special beveling tool. For example, a plate beveling machine is used to cut angles on flat parts. A pipe beveler is used to cut angled edges on pipes or tubes.

To make a chamfer, you can use a regular milling machine with a chamfer end mill. If you’re working with round parts, you can also create chamfers using a lathe with a process called rotary broaching.

In some cases, you can use a chamfer tool to cut a bevel if the angle matches. But in CNC machining, this takes more time because the tool has to make several passes, which can slow down production.

Chamfer vs Bevel: Function

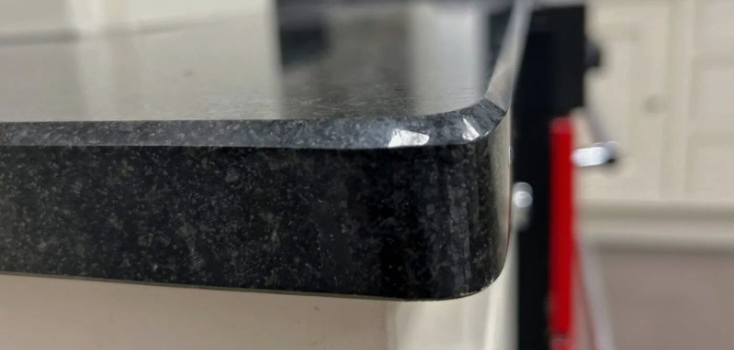

A chamfer mainly removes sharp corners, which helps keep parts safe to handle. It also makes parts look better. For example, when you add chamfers to furniture like mirrors or glass tables, it gives them a clean and stylish look. Chamfers can also help reduce stress in certain areas, making the part stronger and better at handling loads.

Beveled edges help parts fit together more smoothly. They create joints or angled edges that make assembly easier and more accurate. Bevels also improve how a part looks. Removing sharp right-angle edges gives a smoother finish and can make the product look more carefully made.

Chamfer vs Bevel: The Technical Perspective

From a technical point of view, a chamfer is actually a type of bevel. But there’s an important difference. A chamfer is usually cut at a 45° angle and connects two surfaces that meet at a corner. It’s a quick and simple way to remove sharp edges.

A bevel, on the other hand, can be made at almost any angle, except for 45° or 90°. Bevels are often used when you need a smoother transition between two parallel surfaces, or when the part needs a specific fit or look. So while all chamfers are bevels, not all bevels are chamfers.

Chamfer vs Bevel in Aesthetic and Functional Realms

Rounded chamfers, also called fillets, are one of the most common and useful types of chamfers in design. Today’s products often use smooth, curved shapes to look more modern and stylish. Because of this, rounded chamfers are used more and more in product design.

A rounded chamfer softens the edges and makes the transitions between surfaces look natural and clean. Beveled edges, on the other hand, look more like a straight cut. They’re usually added to the outer edges of a part for both function and appearance.

Chamfer vs Bevel: Angle

When you machine a chamfer, it’s usually made at standard angles like 30°, 45°, or 60°. The 45° chamfer is the most common and is often used on shafts, holes, or edges to remove sharp corners, make parts safer to handle, and help with easy assembly.

A bevel, on the other hand, and as mentioned earlier, can be made at almost any angle, depending on the design. Unlike chamfers, bevels are not limited to just a few standard angles. You might use a bevel when the part needs a smoother transition or when two surfaces need to join at a custom angle. This makes bevels more flexible, especially when you need a specific fit, better strength, or a certain look.

Choosing Between Bevels and Chamfers

Here are the main things you need to consider when choosing between chamfers and bevels:

Structure

Chamfers don’t always provide strong joints, since they have less surface area to hold onto the base material. Bevels give more contact and help make a stronger bond. They can also add thickness, which improves the strength of the part.

Visual Impact

Chamfers are often used to make parts safer and better-looking. For example, on glass or mirrors, chamfers remove sharp corners and add a clean edge. They also make bolts and other parts easier to handle and less likely to crack. Bevels, on the other hand, can look sharp and clean, but they may be weaker because their edges are thinner and more likely to crack.

Время и стоимость

Both bevels and chamfers take extra time and money to machine. They can slow down production, so you should only add them if they’re really needed. Think about the design, function, and strength before choosing one.

Raw Material Compatibility

If you’re working with complex parts or wood, bevels are often better. They help parts fit together smoothly and allow for strong connections. But if you want something easier to fit without damaging the material, go with a chamfer, especially one with a blunt tip.

Professional Guidance

If you’re not sure which one to use, talk to a professional. A structural engineer can help you choose the right edge based on your part’s shape, material, and use.

Why Design Chamfers and Bevels for the Parts?

Now, let’s go over some common reasons to add chamfers and bevels to your machined parts.

Provide Safety

Sharp corners on parts can be dangerous. They can cause cuts or get caught on clothing. A chamfer removes the sharp edge and makes the part safer to handle. You often see this in tables, counters, and machined parts.

A bevel also softens the edge, especially on corners, but it can leave another sharp point. That’s why bevels are better for parts that don’t need to be touched often.

Assembly and Disassembly

Chamfers and bevels help parts fit together more easily. Chamfered edges guide bolts, screws, or other pieces into place. That’s why many nuts and bolts have chamfered heads, as they’re easier to grip and less likely to crack.

Bevels are helpful for joining large surfaces, like wood panels. They give better surface contact and make the connection stronger and easier to take apart.

Decorative Purpose

Both chamfers and bevels improve how a part looks. Removing sharp edges makes the design look cleaner and more professional.

Chamfers are common in woodworking to give smooth, finished edges. Bevels are also used in jewelry or decorative parts to add style and dimension.

Fit and Alignment

Angled edges make it easier for parts to line up and fit properly. A chamfer gives a smooth path to guide parts together, like when inserting a bolt into a hole.

Bevels help large or complex parts connect by giving more surface area and creating a tight, accurate fit.

Reduced Friction

Chamfers and bevels make parts slide more smoothly and reduce wear.

In cars, bevel gears use angled teeth to move better and reduce friction. Chamfered brake pads help lower noise and vibration when braking.

Manufacturability

Adding chamfers or bevels can increase machining time, but good planning helps. If you design them into the part early, they can be made faster using special tools or dies.

You can also save time by using looser tolerances when высокая точность isn’t needed. In some cases, chamfering a corner is even faster than machining a perfect right angle.

Заключение

Chamfers and bevels improve safety, fit, and how a part looks, but they’re used in different ways. Use chamfers when you want quick edge removal, easier assembly, or a clean finish. Choose bevels when you need smoother transitions, stronger joints, or a custom look.

Связаться с компанией DEK if you need help adding the right chamfers or bevels to your parts. We offer high-precision machining with expert design support. We can shape your parts exactly the way you need them, fast, accurately, and cost-effectively. Message us today to get started!

Вопросы и ответы

Are chamfers always 45 degrees?

No, chamfers are not always 45°. While 45° is the most common because it’s easy to make and works well for many parts, you can see chamfers at many other angles, like 30°, 60°, or anywhere between about 15° and 75°, depending on your needs and design.

What are the differences between chamfer vs bevel vs fillet?

A chamfer is a flat, angled cut (often 45°) used to remove sharp corners. A bevel is also an angled edge, but it can be at any angle and usually connects larger or parallel surfaces. A fillet is different because it has a rounded, curved edge instead of a straight cut.

You use chamfers for easier fitting and safety, bevels for strong joints or style, and fillets to reduce stress and make smoother transitions.

Why are bevels important in welding?

Bevels are important in welding because they help the weld go deeper and create a stronger joint. When you bevel the edge of a thick part, it gives space for the weld to fully fill the gap and bond better. This helps prevent weak spots, cracks, and makes the weld last longer. If you’re welding thick metal or pipes, adding a bevel is the best way to get a strong, clean weld.