- Início

- Construção

High Quality Custom Construction Parts Manufacturing

DEK specializes in the precision manufacturing of machined parts for the Construction industry. We offer high-quality, durable components to customers worldwide with industry-leading speed and at cost-effective prices. We can rapidly machine complex parts with tight tolerances of +/- 0.005mm, utilizing a wide range of production-grade materials and surface finish options. Get an instant quote!

- Competitive Price & Reliable

- 24/7 Engineering Support & DFM

- ISO 9001:2015 Certified.

- Rotação rápida, prazo de entrega curto, não MOQ

Precision Parts Manufacturing in the Construction Industry

DEK is your trusted partner for precision-machined custom parts for the construction industry, known for exceptional quality and service. Our parts are built to perform reliably in high-vibration and extreme weather environments.

As an ISO 9001 certified manufacturer, DEK offers advanced machining capabilities with tolerances up to ±0.005mm. We strictly adhere to construction industry standards, specializing in machining corrosion-resistant, high-strength materials such as stainless steel, alloy steel (e.g., 4140, 4340), ensuring every part delivers superior performance and exceptional durability.

Additionally, we offer surface treatments including passivation, electroplating, PVD coating, and QPQ coating. Our typical applications include architectural hardware, steel structure connectors, aluminum profiles, custom bolts, and nuts. We provide CMM inspection reports, FAI reports, and material certificates. Contact us now to quickly obtain your quote.

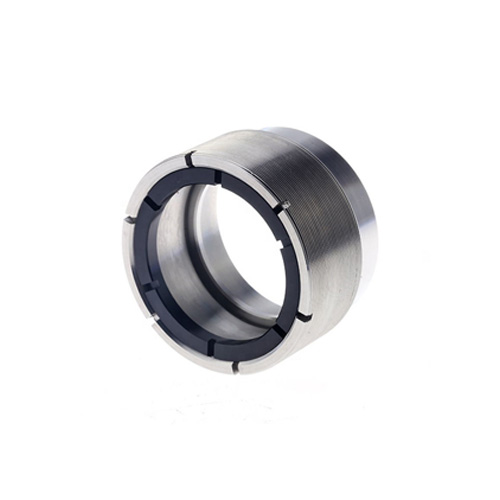

Machined Part

Machined Part

Suporte

Suporte

Turned Part

Machined Part

Construction Component Capacidades de fabrico

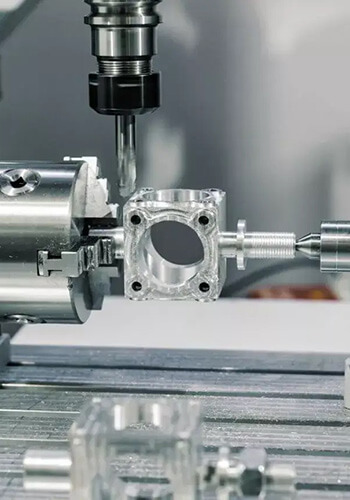

Maquinação CNC de precisão

DEK offers fast, accurate, and reliable CNC precision machining services with tight tolerances up to ±0.005mm, ideal for manufacturing steel structural connectors, custom anchor bolts, precision shims & spacers, and brackets.

We specialize in 5-axis machining for complex, high-precision construction components. We provide rapid prototyping services and free DFM analysis to reduce costs. Whether you need a functional prototype or a reliable partner for small-batch production, DEK delivers flexible and efficient solutions.

Fabrico de chapas metálicas

DEK specializes in machining high-quality custom sheet metal parts for the construction industry. From metal frames to equipment enclosures, we provide reliable structural support and protection for your core components.

We offer a variety of sheet metal materials, including aluminum, stainless steel, and steel. From instant quotes to rapid production, you can receive hundreds of high-quality sheet metal parts in just a few days. Additionally, we provide surface treatment options, including brushing, anodizing, and coating, to meet your parts’ demanding requirements.

Impressão 3D industrial

DEK offers advanced additive manufacturing technologies, including metal 3D printing, SLA, SLS, and FDM, enabling low-cost rapid prototyping and the production of durable, corrosion-resistant parts with complex geometries.

We provide a wide range of metals and plastics, including stainless steel, alloy steel, PEEK, and PTFE, for printing special-shaped steel structure joints, corrosion-resistant pipe flanges, and high-stress building anchor bolts. Additionally, we offer surface treatments tailored to your project’s needs.

Materiais

Materiais Opções

Aço inoxidável

This high-performance metal, renowned for its exceptional corrosion resistance, high strength, and fire-resistant properties, is the preferred material for architectural structural components, functional parts, and aesthetic or decorative applications.

Aço carbono

Carbon steel offers excellent machinability, weldability, and mechanical properties, making it widely used in the construction industry. It is ideal for manufacturing building frames, custom bolts, and rivets. Additionally, we provide DLC and PVD coating options.

Aço de liga leve

Alloy steel is a high-strength, high-temperature resistant, and wear-resistant metal. It is the preferred material for drill pipes, flanges, tubing heads, high-pressure fasteners, and connectors, and it has excellent low-temperature impact toughness and good machinability.

Alumínio

Aluminum is lightweight, corrosion-resistant, easy to process, and aesthetically pleasing, making it ideal for large-span structures and high-rise buildings by reducing foundation loads. It is perfect for manufacturing curtain wall profiles, structural components, connectors, and aluminum composite panels.

Instantâneo & Citações exactas

Não utilizamos ferramentas de cotação automatizadas em linha, porque são muito imprecisas. As plataformas de cotação em linha baseiam-se apenas em cálculos baseados em montantes de corte e coeficientes fixos, não tendo em conta as nuances reais do processamento, tais como a deformação do material após o tratamento térmico, requisitos de tolerância apertados, retificação após o tratamento térmico, etc. Consequentemente, os cálculos automáticos de preços podem levar a imprecisões, aumentando, em última análise, os seus custos.

Mas pode ficar descansado com a DEK!

Os nossos orçamentos são económicos e precisos porque temos uma equipa de engenheiros mecânicos profissionais que analisam meticulosamente cada desenho. Estes engenheiros têm mais de 10 anos de experiência e possuem conhecimentos profundos em programação, funcionamento de máquinas, pós-processamento, propriedades dos materiais e muito mais. Garantimos que receberá orçamentos exactos no prazo de 6 horas.

Porquê escolher Os nossos serviços

A produção de peças de alta qualidade num só local permite-lhe poupar tempo e dinheiro.

Capacidades de engenharia

Prazo de entrega rápido

Controlo de qualidade

Acabamentos de superfície

Montagem de precisão

Packaging and Logistics

O nosso Processo de encomenda

Enviar RFQ

Enviar RFQ com desenhos 2D/3D e requisitos detalhados por correio eletrónico ou formulário online.

Crítica e cotação

A nossa equipa de engenheiros analisará cuidadosamente cada desenho e fornecerá um orçamento preciso no prazo de 6 horas.

Confirmar a encomenda

Confirme o orçamento, os pormenores e o calendário de entrega e, em seguida, assine o contrato.

Produção

Organizar o processo de produção, iniciar a programação e a maquinagem.

Controlo de qualidade

Controlo de qualidade rigoroso durante a produção e a inspeção final.

Embalagem e expedição

Embale as peças, coloque etiquetas de identificação das peças e inicie a expedição.