Nylon is one of the most popular synthetic materials in manufacturing. You can find it in everything from car parts to clothing because it’s strong, flexible, and wear-resistant.

But if you want to work with Nylon successfully, you need to understand one key property: the melting point of Nylon. Getting the temperature right is important if you want to mold or shape it properly.

O que é o nylon?

Nylon is the first synthetic material made entirely from oil-based chemicals. Its structure consists of long chains connected by strong bonds. The two main types are Nylon 6 and Nylon 6,6, named after the number of carbon atoms in their structure.

Nylon is well-known for its strength, elasticity, and resistance to wear, heat, and chemicals. It also has low friction, which is why it is useful for mechanical parts.

What is the Melting Point of Nylon?

The melting point of Nylon is very important when making products from it. It helps you know how well Nylon will perform in different temperatures. The exact melting point can change based on how it was made.

Melting Points of Common Nylon Types

Nylon 6: This type of Nylon melts at around 215°C to 220°C (419°F to 428°F).

Nylon 6,6: This type has a higher melting point than Nylon 6, melting at around 255°C to 265°C (491°F to 509°F).

Why Nylon’s Melting Point Matters?

When you’re working with moldagem por injeção, Nylon’s melting point is very important. Here’s why:

Helps Nylon Flow Properly

If the temperature is too low, the Nylon won’t flow well into the mold. This can cause missing parts or defects. If it’s too hot, the Nylon can break down and cause wear or poor-quality parts.

Keeps Production Fast and Smooth

The melting point affects how long the Nylon takes to cool. When you keep the right temperature, the parts cool quickly and properly. This means you can make more parts faster without losing quality.

Protects the Material

If you overheat Nylon, it can burn or change color. It might also lose strength. Keeping the temperature just right helps keep the Nylon strong and clean.

Factors Affecting the Melting Point of Nylon

Here are some of the factors that may affect the melting point of Nylon:

Type of Nylon: Different types of Nylon melt at different temperatures. So, make sure you know which type you’re working with.

Molecular Structure (Crystallinity): When Nylon’s molecules are packed tightly and lined up well, it melts at a higher temperature. If they’re more spread out or random, it melts at a lower temperature. So, how Nylon is made or cooled affects this.

Molecular Weight: If the Nylon has longer or heavier molecules (called high molecular weight), it needs more heat to melt. That means you’ll need to raise the temperature.

Additives: If you add things like plasticizers, fillers, or other chemicals, they can change the melting point. Some will lower it, and others might raise it. Always check what’s been added to your material.

Moisture Content: Nylon pulls in moisture from the air. If you don’t dry it before use, that moisture can lower the melting point and mess up your process. Dry it well to avoid problems.

Processing Conditions: The way you cool and shape Nylon affects how its molecules arrange. If you cool it fast, it might be less organized, which lowers the melting point. If you cool it more slowly, the melting point may be higher.

Other Thermal Properties of Nylon

Aside from knowing the melting point of Nylon to make sure your product works well, you also need to understand these other key points about how Nylon reacts to heat:

Glass Transition Temperature (Tg)

This is the temperature where Nylon starts to soften, almost like rubber.

Nylon 6: Softens around 50°C to 60°C (122°F to 140°F).

Nylon 6,6: Softens around 60°C to 70°C (140°F to 158°F).

Condutividade térmica

Nylon doesn’t carry heat very well, which means it’s a good insulator. You’ll often see it used for things like pan handles, heat pads, and even in electrical parts.

Expansão térmica

When Nylon heats up, it expands. This expansion is moderate, but you should keep it in mind to make sure your parts don’t get damaged by heat. The expansion rate is usually around 80-100 x 10⁻⁶ /°C.

Heat Deflection Temperature (HDT)

This is the temperature at which Nylon starts to bend or change shape under pressure.

Nylon 6,6: Usually starts to deform between 100°C to 150°C (212°F to 302°F), depending on how it’s made and if it has any added materials.

Decomposition Temperature

Melting and decomposing are different. Nylon starts to melt at a certain point, but if the temperature goes even higher, around 300°C (572°F), it starts to break down. It may lose its strength, change color, and its chemical structure can be damaged.

Resistência ao fogo

Nylon is more fire-resistant than many plastics because of its high melting point. But it can still catch fire if the temperature is too high. Some types of Nylon have special additives to help them resist fire even more.

Applications Where Nylon’s Melting Point is Critical

These are some common areas where the melting point of Nylon is important:

Car Parts

If you’re using Nylon in cars, especially around the engine, the heat can get intense. You might find Nylon in coolant tanks, air intake pipes, or under the hood. Even gears and bearings made of Nylon can get very hot due to friction. So, you need to make sure the melting point is high enough to handle these temperatures and avoid damage.

Electrical and Electronic Devices

You’ll often see Nylon in things like electrical connectors, cable ties, covers, and insulation. If these parts get hot, especially near wires or power sources, they need to hold their shape and stay safe. A high melting point helps make sure they don’t melt or break down.

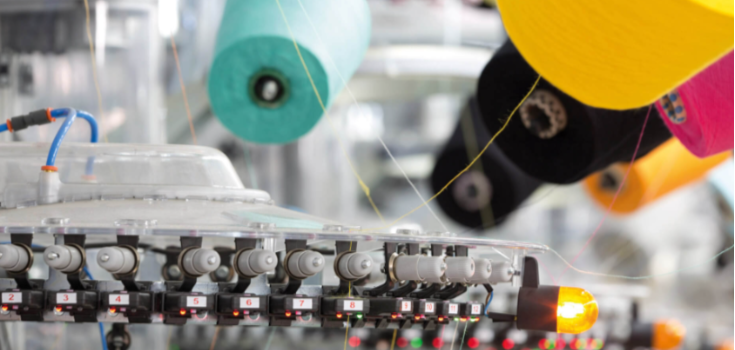

Clothing and Textiles

When you’re using Nylon in clothes like outdoor gear, sportswear, or military uniforms, the fabric needs to handle heat. Whether it’s from hot weather, washing, or drying, Nylon must stay strong and not break down. That’s why a good melting point is so important here.

Aircraft and Aerospace

In airplanes, Nylon is used for parts because it’s light, strong, and flexible. Planes deal with extreme temperatures, so the Nylon you use must have a high enough melting point to stay safe and perform well during flight.

Everyday Household Products

You probably use Nylon every day in things like pot handles, plastic plates, cups, and kitchen tools. These items get hot, so they need to resist melting. A good melting point makes sure they stay safe to use and don’t change shape when exposed to heat.

Compare Nylon Melting Point with Other Polymers

Now, let’s compare Nylon to other plastics to help you make a choice on what to use.

Polietileno (PE)

Polietileno melts at a much lower temperature than Nylon. If you use Low-Density Polyethylene (LDPE), it melts at about 105°C to 115°C (221°F to 239°F). High-Density Polyethylene (HDPE) melts at about 120°C to 130°C (248°F to 266°F). Because of this, you shouldn’t use PE for anything that gets very hot.

Polipropileno (PP)

Polipropileno has a melting point of about 160°C to 170°C (320°F to 338°F). This is still lower than Nylon, so it works for medium heat but not for high temperatures.

Cloreto de polivinilo (PVC)

Polyvinyl Chloride melts at around 160°C to 210°C (320°F to 410°F). This is close to the melting point of Nylon 6, but it’s usually lower than Nylon 6,6. You can use PVC for some heat applications, but it may not be as strong in high heat.

Polystyrene (PS)

Poliestireno can melt at around 240°C (464°F), which is close to Nylon 6,6. But polystyrene breaks more easily when it gets hot, so it’s not as strong or durable as Nylon.

Policarbonato (PC)

Polycarbonate melts at about 260°C to 270°C (500°F to 518°F), which is similar to or slightly higher than Nylon 6,6. If you need a clear plastic that can handle high heat, Polycarbonate is a good choice.

Tereftalato de polietileno (PET)

Polyethylene Terephthalate, or PET, has a melting point of about 250°C to 260°C (482°F to 500°F). This is close to Nylon 6,6. PET is used in things like drink bottles and clothes because it can handle heat and stress well.

Conclusão

The melting point of Nylon is important for making sure it performs well and stays safe in different uses. Nylon 6,6, in particular, can handle high temperatures without losing its strength. This makes Nylon a great choice for tough environments.

Em DEK, we specialize in creating custom Nylon parts with precision using advanced Nylon injection molding services. Our top-notch technology and experienced team make sure each part meets your exact needs, providing excellent durability and performance. Contact us today and get a free quote.

FAQs

What is the melting point of Nylon 6 and Nylon 6,6?

Nylon 6 melts at approximately 218.3°C (424.9°F). Nylon 6,6 has a higher melting point of around 255°C (491°F).

What is the melting point of Nylon 12?

Nylon 12 melts at 178–180°C (352–356°F), so it is one of the lower-melting nylons.

Is Nylon toxic?

Nylon itself is generally not toxic. However, during its production and processing, chemicals like caprolactam and additives such as flame retardants, dyes, and metals can be used. These substances may pose health risks, including potential hormone disruption and increased cancer risk.

Additionally, Nylon contributes to microplastic pollution, which can harm marine and aquatic ecosystems.