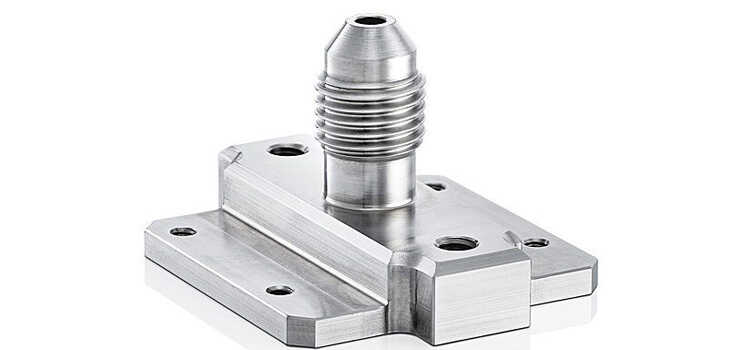

Sensor housings are important components in various industries. It's important to ensure high accuracy when machining them.

From temperature sensors that control the climate in commercial buildings to barrel proximity sensors used in robotics and manufacturing plants, CNC machined sensor housings play an essential role.

These components can be made from plastic or metal materials. Aluminum alloys are often used for superior strength and stiffness.

Knowing the types of sensor housing required and using high-quality materials is key to achieving successful results with a CNC machine.

The Importance Of High Accuracy In CNC Machining A Sensor Housing

A well-machined sensor housing protects sensitive components from external factors while maintaining accurate readings and optimal performance.

Benefits of CNC Machining a Sensor Housing

- Improved functionality for sensors

- Avoid faulty readings or energy costs due to misalignment

- Increased customer satisfaction

- Higher quality PCBs and sensor replacement

- High accuracy leads to a more cost-effective product overall

- Manufacturers who produce superior parts gain better reputations

Challenges In CNC Machining a Sensor Housing

- Distortion caused by thermal stress during machining

- Wear and tear on cutting tools

- Deformation due to improper clamping or inappropriate cutting parameters

- Inaccuracies caused by errors in part zero, programming, and toolpath optimization.

Sensor Housing Types

Weatherproof Housing

These housings protect sensors from outdoor weather conditions, including rain, snow, and sunlight. They are typically sealed to prevent moisture ingress and are often made from materials that can withstand UV exposure.

Submersible Housing

These housings protect sensors when submerged in liquids. They are often used in underwater monitoring, wastewater treatment, and marine research applications.

Explosion-Proof Housing

Sensors in potentially explosive or hazardous environments, such as oil refineries or chemical plants, require explosion-proof housing. These housings are designed to contain any explosion within the enclosure and prevent igniting surrounding gases or vapors.

Dustproof Housing

In environments with dust or particulate matter, sensors may require dustproof housings to prevent clogging and damage to sensitive components.

Vandal-Resistant Housing

Sensors deployed in public spaces or areas at risk of vandalism may be housed in strong, impact-resistant enclosures to prevent damage from deliberate tampering or physical abuse.

High-Temperature Housing

Some industrial applications involve high-temperature environments, such as foundries or steel mills. High-temperature housings protect sensors from extreme heat while ensuring accurate operation.

Low-Temperature Housing

In applications such as cold storage or Arctic research, sensors may require low-temperature housings to ensure their functionality in freezing conditions.

Airtight Housing

These housings are tightly sealed to prevent air entry or other gases. They are used in applications where maintaining a specific gas composition or pressure is critical.

Hygienic Housing

Sensors used in food and beverage industries, pharmaceuticals, or medical settings often require hygienic housings that are easy to clean and resistant to contamination.

Transparent or Windowed Housing

Some applications require transparent housing or a window through which the sensor can interact with the environment, such as optical sensors or cameras.

Hazardous Area Housing

These housings are designed for sensors in areas with flammable gases, vapors, or dust. They are certified to meet safety standards for such environments.

Ruggedized Housing

Rugged sensor housings are built to withstand harsh conditions, including shock, vibration, and extreme weather, making them suitable for outdoor and industrial applications.

Materials Commonly Used for Sensor Housings

- Alumínio

- Aço inoxidável

- Plastics (ABS, Polycarbonate, etc.)

- Die-Cast Zinc or Magnesium

- Encapsulating Compounds

- Fiberglass Reinforced Plastics (FRP)

- Cerâmica

- Metal Alloys (e.g., Titanium)

- Materiais compósitos

- Hybrid Designs

5 Tips for CNC Machining a Sensor Housing with High Accuracy

1. Choosing The Right CNC Machine And Tooling

A CNC machine with a high rigidity, stability, and precision level is essential to prevent deformation during cutting. Selecting the right tooling based on the material used and the desired surface finish.

For example, a carbide cutter can improve cutting speed compared to traditional high-speed steel cutters.

2. Using High-Quality Raw Materials

Substandard materials can result in inconsistencies, defects, and inaccuracies that can compromise the functionality and reliability of the part. As such, manufacturers must prioritize using high-quality raw materials from reputable suppliers.

One example of this is selecting aerospace-grade aluminum for precision machining. Aluminum is widely used due to its desirable properties like low weight-to-strength ratio, corrosion resistance, and machinability.

However, not all grades are created equal. For example, aerospace-grade aluminum alloys like 7075 or 2024 are known for their exceptional strength and stiffness, which make them ideal for making critical parts like sensor housings that require high-precision tolerances.

Another essential aspect of using high-quality raw materials in CNC machining is ensuring consistency by adhering to specifications during procurement and handling.

Maintaining consistent material quality involves proper storage procedures to prevent contamination or exposure while keeping detailed records of incoming material inspections and any out-of-spec deviations encountered.

3. Prioritizing Precision And Calibration

This involves ensuring that the machine tools are calibrated and maintained regularly to maintain their accuracy.

In addition, simple maintenance procedures like cleaning the machines' surfaces, changing worn-out cutting tools, and inspecting fixtures can help minimize errors in production.

Another critical aspect of precision is part zero - accurately setting up workpieces on the machine. This ensures that every cut is precise without any deviation from specified dimensions.

Proper alignment of fixtures also helps maintain consistency in production workflow while minimizing cycle times. By optimizing these processes, manufacturers can improve efficiency while reducing costs significantly.

4. Monitoring And Adjusting Machining Parameters

Here are some tips to ensure precision and consistency throughout the process:

- Set up a real-time data collection and analysis system to detect deviations from the ideal parameters.

- Record the most effective parameters for each tooling operation to shorten setup times for future jobs.

- Use tools that provide accurate readings and operate within acceptable tolerances.

- Regularly recalibrate machines, particularly after significant changes such as equipment upgrades or repairs.

- Train operators to spot potential issues with machine operations and make necessary adjustments.

5. Employing Advanced Measurement Techniques

This involves using sophisticated measuring tools and equipment capable of inspecting even the tiniest details to ensure it meets the required specifications.

Some examples of advanced measurement techniques include coordinate measuring machines (CMM), laser scanning, and optical inspection systems.

These tools allow for precise measurements of dimensions such as surface roughness, flatness, roundness, or concentricity tolerances.

Using these technologies, you can detect deviations from ideal part geometry before they become costly mistakes down the production line.

In addition to ensuring consistent quality control throughout your manufacturing process, employing advanced measurement techniques will also improve efficiency by reducing time spent on manual checks while improving overall yield for your business.

Conclusão

To achieve high accuracy in CNC machining sensor housings, there are several key steps you need to follow. First, it is important to choose the right machine and tooling.

Second, opt for raw materials known for their superior quality to ensure the durability and reliability of the sensor housings.

Next, prioritize precision and calibration throughout the production process. Additionally, monitoring and adjusting parameters is important for optimal results.

Finally, utilize cutting-edge measurement tools and methods to ensure the parts meet all client specifications.