- Startseite

- Ressourcen

- Technische Kunststoffe: Eigenschaften, Arten und Verwendungen

Technische Kunststoffe: Eigenschaften, Arten und Verwendungen

Engineering plastics are high-performance polymers made to replace metal in many industrial parts. If you’re working with parts that need strength, temperature resistance, or high performance, read this blog to know how engineering plastics can make a big difference in how your product performs and lasts.

Was sind technische Kunststoffe?

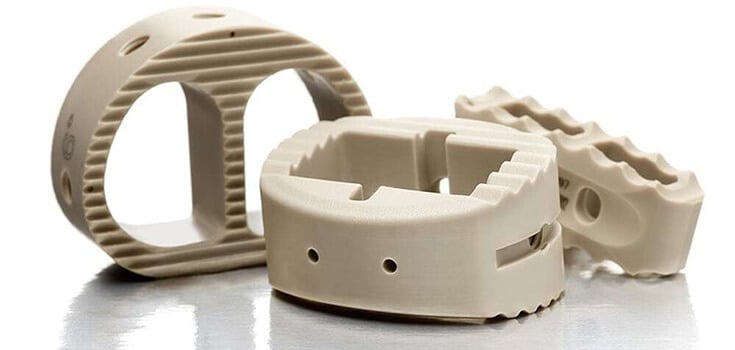

Engineering plastics are special types of plastics made to be stronger and more durable than regular ones. They can handle heat, pressure, and chemicals better, so you can use them for tough jobs like gears, bearings, and medical parts.

Engineering plastics work well in demanding environments. You can make engineering plastic parts through injection molding, extrusion, or even 3D printing.

What is the Importance of Engineering Plastics?

Engineering plastics are used in many industries, such as automotive, aerospace, electronics, medical, and consumer goods. You can use them when metal is too heavy, costly, or rust-prone, and when regular plastics aren’t strong enough.

They are tough, lightweight, and resist heat, impact, and chemicals. Engineering plastics give you a good balance of strength, cost, weight, and durability.

Technische Kunststoffe vs. Commodity-Kunststoffe

Commodity plastics are the common plastics you see in everyday items like bottles, packaging, and containers. They include materials like polypropylene, polyethylene, PVC, and polystyrene. These plastics are cheap and easy to make, but not very strong.

Engineering plastics, on the other hand, are stronger and can handle more stress, heat, and chemicals. Examples include polycarbonate and nylon. You can shape or machine them easily, and they stay stable even at 120–150°C. They are light, tough, and durable—perfect for parts used in cars, medical devices, and electronics.

They cost more than regular plastics, so you usually use them for smaller or high-performance products.

Eigenschaften von technischen Kunststoffen

Abrasion Resistance: You can count on engineering plastics to resist scratches and wear. This makes them great for moving parts like gears and rollers.

Chemische Beständigkeit: They don’t easily react with oils, solvents, or chemicals, so you can use them in machines, medical tools, and kitchen items.

Dimensional Stability: They keep their shape even when it’s hot or cold, perfect for automotive and aerospace parts.

Electrical Properties: Most engineering plastics don’t conduct electricity, so you can safely use them in electrical and wiring parts.

Flammability: Some types don’t catch fire easily, making them ideal for high-risk areas like chemical plants.

Food Compatibility: Certain plastics, like PET and ABS, are safe for food contact, while others, like polycarbonate, are not.

Impact Strength: They can handle sudden hits or shocks, which makes them useful for covers, guards, and housings.

Thermal Resistance: They can handle both high and low temperatures without breaking or melting. PEEK, for example, works well up to 250°C.

Sliding Properties: They slide smoothly with little friction, so they last longer in parts like bearings, pulleys, and implants.

UV-Beständigkeit: They don’t easily fade or weaken in sunlight, making them good for outdoor use.

Water Absorption: They don’t soak up water, so you can use them in wet or humid environments.

Most Common Types of Engineering Plastics

You might see different lists of common engineering plastics. This list shows the types you're most likely to find across many industries.

PET (Polyethylene Terephthalate)

You often see PET in bottles, food containers, and clothes. It’s strong, cheap, and easy to recycle. But it can’t handle high heat and isn’t biodegradable.

ABS (Acrylnitril-Butadien-Styrol)

ABS is used in car parts, electronics, and household items. It’s tough, light, and affordable. However, it burns easily and can wear out with repeated stress.

PC (Polycarbonat)

You can use PC for safety glasses, windows, and machine guards. It’s strong, clear, and fire-resistant. But it scratches easily and expands when heated.

Acrylic/PMMA

You know PMMA as acrylic. It’s clear, strong, and light, so it is perfect for windows, shields, and taillights. It also resists scratches, heat, and chemicals, and you can easily mold or machine it into parts.

PPO (Polyphenylene Oxide)

PPO is tough, hard, and heat-resistant. It keeps its shape well and handles temperatures up to about 195°C. You can use it for car parts, electrical components, and other high-heat applications.

POM (Polyoxymethylen)

POM is very strong, stiff, and wear-resistant. You can easily shape it into gears, fasteners, bearings, and other precision parts.

PBT (Polybutylene Terephthalate)

PBT is like PET but stronger and more stable. It resists heat, moisture, chemicals, and UV-Licht. You can use it for car parts, power tool housings, and electrical enclosures.

HDPE (High-Density Polyethylene)

HDPE is a strong, affordable plastic made from petroleum. It resists impact, chemicals, and corrosion. You can safely use it for food contact, and it’s recyclable, which helps reduce waste.

PEEK (Polyether Ether Ketone)

PEEK is strong, stiff, and works well even at very high temperatures (up to 250°C). It also resists chemicals. You can use it for parts like bearings, seals, valves, electrical connectors, and medical devices.

PPS (Polyphenylene Sulfide)

PPS is tough and heat-resistant, handling temperatures up to 260°C. It’s stable, resists chemicals, and insulates electricity. You can use it for machine parts, bearings, and semiconductor components.

Other Types of Engineering Plastics

Nylon 6: It is strong, tough, and resists heat and electricity. You can improve it with glass fiber for extra strength. It’s used for rollers, pulleys, valve seats, and insulators.

Nylon 6-6: This is like Nylon 6 but handles higher temperatures (up to 103°C) and resists chemicals better. You can use it for bearings, bushings, sprockets, belts, and electronics.

Polyimides (PI): Polyimides can handle very high heat up to 370°C. They’re strong, stable, and resist chemicals. You’ll see them in fuel cells, adhesives, and electrical coatings.

Polyamides (PA): Polyamides include materials like nylon. They’re tough, resist impact, and keep their shape. You can use them in clothes, car parts, and machine bearings.

PEI (Polyetherimide / ULTEM®): PEI is strong, rigid, and keeps its shape in heat. It’s a great electrical insulator, so you can use it for fuses, coils, and aircraft interiors.

PEKK (Polyetherketoneketone): PEKK is strong, heat-resistant, and chemical-resistant. You can use it for gears, pumps, and medical implants.

PEK (Polyetherketone): PEK resists heat, fire, and chemicals, working up to 260°C. It’s ideal for gears, bearings, and bushings in aerospace and machinery.

PK (Polyketone): PK is very impact- and wear-resistant—stronger than nylon or PBT. You can use it in automotive, oil, and gas parts.

PSU (Polysulfone): PSU is clear, strong, and safe for food and medical use. It works up to 160°C, ideal for trays and fluid manifolds.

PTFE (Polytetrafluoroethylene / Teflon®): PTFE is slick, flexible, and resists heat and chemicals from -240°C to 260°C. You can use it for cookware, pipes, seals, and wiper blades.

How Does Plastic Engineering Work?

Plastic engineering is about creating and improving plastic materials and products. You study how plastics are made, shaped, and used, from lab research to factory production. The goal is to develop new plastics from natural or petroleum sources that meet specific needs for different applications.

Vorteile von technischen Kunststoffen

- They’re tougher than regular plastics and can handle heavy use.

- They’re much lighter than metals, helping you save weight and energy.

- They resist chemicals, oils, and solvents.

- Some can handle very high or low temperatures.

- Most don’t conduct electricity, so they’re safe for electronic parts.

- They keep their shape well under stress or heat.

- You can mold them into complex or custom shapes.

- Some are naturally smooth, reducing friction and wear.

- Many types can be recycled to reduce waste.

Nachteile von technischen Kunststoffen

- Some types can soften or deform under extreme heat.

- Long UV exposure can make them fade or crack.

- They cost more than standard plastics.

- Some are harder to find or buy.

- They may need special machines or heat to make.

- Additives can make recycling harder for some types.

- Some aren’t fully clear, like glass or acrylic.

- Strong solvents can still damage a few types.

- A few may become brittle in freezing temperatures.

Applications of Engineering Plastics

Here are some of the common engineering plastics examples:

Mechanische Kunststoffteile

You’ll find these in cams, couplings, and gears. They must handle strong impacts, high stress, and heat for long periods without losing shape or strength.

Chemical and Heat-Resistant Parts

These include valve covers, fuel rails, and water pump housings. They need to resist chemicals, corrosion, and high temperatures to last longer.

Electrical Plastic Parts

Used in connectors and relays, these parts must resist electricity, stay strong, and remain stable under different conditions.

Low-Friction Components

These are made to move smoothly with less wear. You’ll see them in bearings, guides, slides, and other wear-resistant surfaces.

Schlussfolgerung

Engineering plastics give you the right combination of strength, durability, and flexibility. They work well when metal is too heavy or when regular plastic isn’t strong enough. You can use them to make lighter and tougher parts for cars, planes, or medical tools.

If you need custom plastic parts made with high accuracy and a smooth finish, DEK is here to help. We can machine or prototype your parts fast and with great quality. Kontakt today to get a free quote!