Spritzgießservice

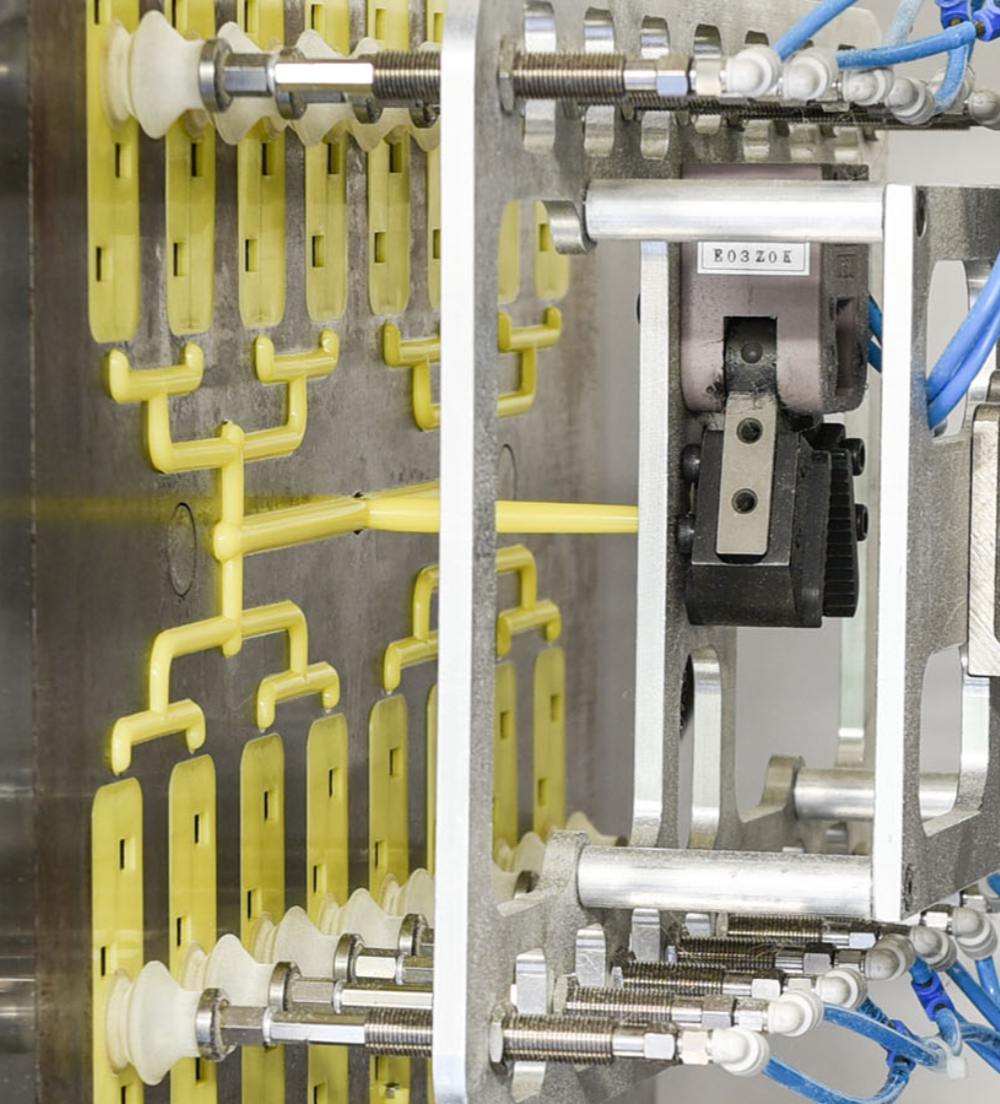

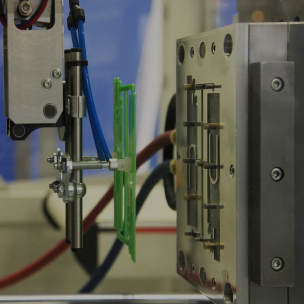

Wir sind spezialisiert auf den kundenspezifischen Werkzeugbau, die Herstellung von Formen und das Spritzgießen mittlerer bis hoher Stückzahlen. Wir bieten auch sekundäre Operationen, Oberflächenbearbeitung und Montageservice an.

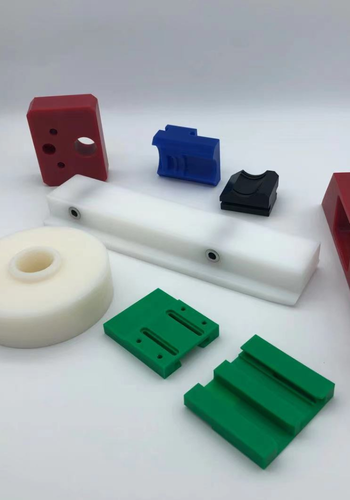

DEK offers precise, cost-effective molded components to clients across several industries. Using specialized molds, our manufacturing technique can produce consistent plastic components. We focus on producing accurate, high-quality molded parts that meet your specific needs. Whether you require a prototype or hundreds to thousands of components, our reliable and swift molding service is up to the task. Our manufacturing process follows a tight precision level of +/-0.005mm, ensuring you get consistent parts all around.

Einführung

Spritzgießen | Consistent, High Precision, Cost-Effective

DEK offers high-quality, consistent, and precise molded components that are cost-effective. Whether you’re ordering in small or large quantities, we offer you relatively fair pricing.

With our specialized molds, team of experts, technological machines and tools, and variety of materials, we give reliable, effective, and efficient injection molding service. We are also ISO 9001, ISO 13485, and AS9100D certified, so you can be sure our manufacturing processes follow strict regulatory compliance.

You can order any amount, as we don’t have an MOQ. Whether you need just simple components or ones with complex geometries, we're here to serve.

- A wide variety of plastics to select from

- Tight tolerance within +/-0.005mm

- End-to-end quality assurance

- Custom finishes and surface treatments

- Professional packaging and worldwide delivery

Materials for Injection Molding

Kunststoffe

ABS

ABS is a tough, impact-resistant plastic known for its strength, rigidity, and ability to withstand everyday wear. It is easy to mold, has good surface finish qualities, and offers decent resistance to heat and chemicals.

At DEK, we use ABS to create durable and high-quality parts for the automotive, consumer electronics, and home appliance industries. These include components like dashboard panels, automotive sensor housing, device enclosures, etc. DEK’s injection molding service guarantees accuracy and reliability across every project, large or small.

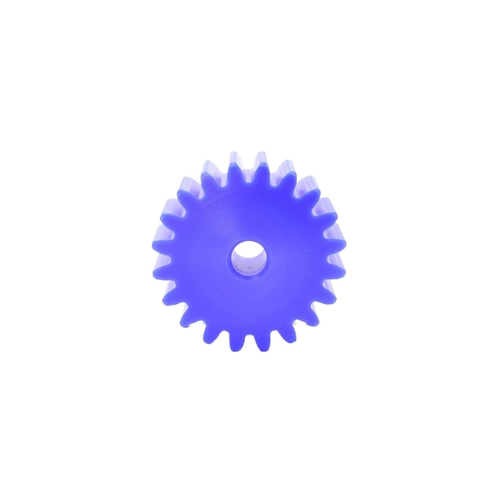

Nylon

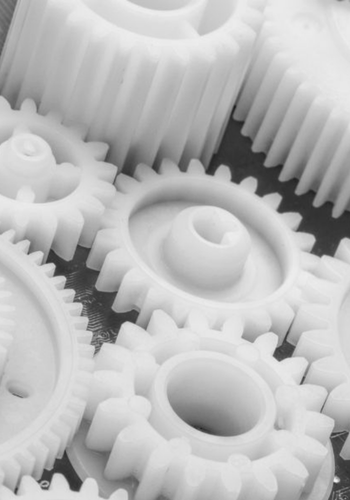

Nylon is a strong, wear-resistant plastic with good thermal and chemical resistance. It performs well in mechanical applications requiring toughness, self-lubrication, and low friction under stress.

At DEK, we mold nylon into high-performance parts used in gears, bearings, and structural components across several industries. We focus on quality and detail; you’ll receive nylon components built to handle demanding conditions with accuracy and endurance that meet your industry’s expectations.

Klassen

Nylon 6, Nylon 6 (30% Glass Filled), Nylon 6/6 (30% Glass Filled), Nylon 6 Flame Retardant.

PC

PC is a strong and transparent plastic with high impact resistance and excellent dimensional stability. It holds up well under pressure and heat, making it suitable for applications requiring clarity and toughness at the same time.

At DEK, we use PC to produce robust and clear parts for lighting, safety gear, and electronics. Our skilled technicians deliver precision-molded components with smooth finishes and accurate detailing. Whether it’s protective casings or lenses, you can count on DEK’s high standards in quality, strength, and clarity to meet your exact industrial requirements with confidence.

PE

PE is a lightweight plastic known for its flexibility, chemical resistance, and moisture tolerance. It can handle low temperatures and repetitive stress, making it popular for packaging and fluid-handling systems.

At DEK, we mold PE into durable, flexible components used in industries like food processing, plumbing, and packaging. Our advanced equipment and skilled team ensure that every part is produced to exact specifications. We focus on delivering smooth surfaces and long-lasting performance, helping you get reliable, cost-effective plastic parts with DEK’s trusted quality and accurate results.

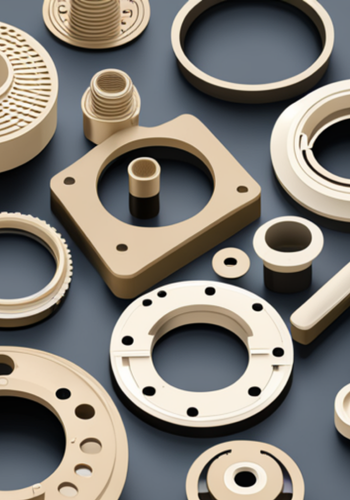

PEEK

PEEK is a high-performance plastic known for its exceptional heat resistance, mechanical strength, and chemical stability. It’s ideal for harsh environments and demanding engineering applications, especially where metal replacement is needed.

DEK uses PEEK to produce ultra-precise, durable parts for aerospace, medical, and electronics sectors. Our machines handle the material’s complexity while delivering excellent surface finish and accuracy. We make sure every part meets tight tolerances and performs reliably under stress. When your applications demand advanced materials and perfect execution, DEK’s expertise with PEEK gives you unmatched quality and precision.

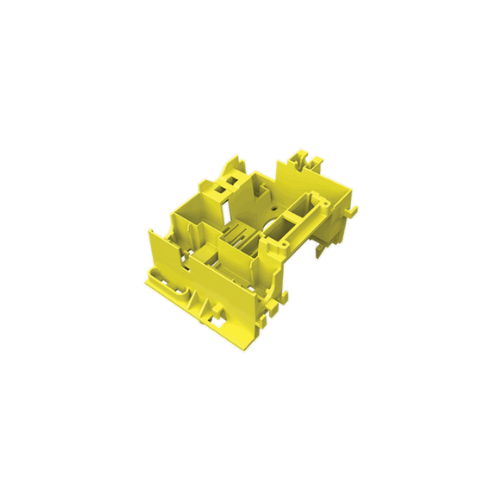

PP

PP is a lightweight, chemical-resistant plastic known for its fatigue resistance and flexibility. It is ideal for applications requiring hinged parts, containers, and medical components due to its durability and low moisture absorption.

At DEK, we use PP to create flexible and functional parts for the medical, packaging, and automotive sectors. Our molding process ensures high precision, consistent wall thickness, and smooth finishes.

Klassen

PP Homopolymer, PP+GF(30%)

TPU

TPU is a flexible and elastic plastic with excellent abrasion resistance, impact strength, and resistance to oils and greases. It’s suitable for parts needing both strength and flexibility, like seals and protective covers.

With DEK’s injection molding service, we mold TPU into rugged, flexible components for industrial, automotive, and medical applications. These components include catheters, connector housing, automotive bushings, etc. We focus on tight tolerances, detailed features, and smooth finishes. We combine high-quality materials with expert craftsmanship so you receive durable, high-precision components designed for real-world performance and reliability.

Vielseitig Oberflächenveredelung Optionen

Eloxieren

Eloxieren ist ein elektrochemisches Verfahren, das die Korrosionsbeständigkeit, die Haltbarkeit und das Aussehen von Metallen, insbesondere von Aluminium, verbessert.

Black Oxide

Mit der Oberflächenveredelung Black Oxide erhalten Sie funktionelle und ästhetische Vorteile in einem. Es handelt sich um eine mattschwarze Oberfläche, die Metalle zusätzlich schützt und Korrosion und Abnutzung im Laufe der Zeit verringert.

DLC-Beschichtung

Der niedrige Reibungskoeffizient von DLC-Beschichtungen verringert den Widerstand zwischen Oberflächen und sorgt so für eine lange Lebensdauer von Komponenten wie Werkzeugen und mechanischen Teilen.

Sofort & Genaue Zitate

Wir verwenden keine automatisierten Online-Kostenvoranschläge, weil sie sehr ungenau sind. Online-Kostenvoranschlagsplattformen stützen sich ausschließlich auf Berechnungen auf der Grundlage von Schnittmengen und festen Koeffizienten und berücksichtigen nicht die tatsächlichen Verarbeitungsnuancen, wie Materialverformung nach der Wärmebehandlung, enge Toleranzanforderungen, Schleifen nach der Wärmebehandlung usw. Folglich können automatische Preisberechnungen zu Ungenauigkeiten führen, die letztlich Ihre Kosten erhöhen.

Aber bei der DEK können Sie beruhigt sein!

Unsere Angebote sind sowohl kosteneffizient als auch präzise, da wir über ein Team professioneller Maschinenbauingenieure verfügen, die jede Zeichnung sorgfältig prüfen. Diese Ingenieure haben mehr als 10 Jahre Erfahrung und verfügen über fundierte Kenntnisse in den Bereichen Programmierung, Maschinenbetrieb, Nachbearbeitung, Materialeigenschaften und mehr. Wir versichern Ihnen, dass Sie innerhalb von 6 Stunden genaue Angebote erhalten.

Unsere Vorteile

2300+ Ingenieure Liebe Arbeit mit uns

Hohe Präzision

We ensure every part is produced with tight tolerances and exact dimensions. At DEK, we focus on delivering consistent accuracy for even the most detailed components. Your parts will fit, function, and perform just as expected every single time.

Complex Geometry

Whether your part includes undercuts, thin walls, or internal channels, our molding process and tooling capabilities can handle it all. You can rely on us to turn even your most challenging designs into fully functional and perfectly molded components.

Zertifizierte Qualität

We follow internationally recognized standards and perform strict quality checks throughout the production process. You’ll receive parts that meet your industry’s performance and safety requirements, backed by ISO certifications and full inspection reports.

Oberflächenveredelung

Beyond molding, DEK offers a range of surface finishing treatments to enhance the appearance and performance of your parts. From smooth polish to textured finishes, we tailor the final look to match your application.

Kosteneffizienz

Our efficient production systems and material optimization reduce waste and labor, saving you money without compromising quality. At DEK, you receive top-tier injection molding services at competitive prices.

Material Vielseitigkeit

DEK supports a wide range of plastics. This gives you the freedom to choose the right material for your application. Whatever your industry or performance requirement, we help you select and mold the ideal material to bring your part to life.

Unser Bestellvorgang

RFQ senden

Senden Sie eine Anfrage mit 2D/3D-Zeichnungen und detaillierten Anforderungen per E-Mail oder Online-Formular.

Rezension & Zitat

Unser Ingenieurteam wird jede Zeichnung sorgfältig prüfen und innerhalb von 6 Stunden ein genaues Angebot erstellen.

Bestellung bestätigen

Bestätigen Sie den Kostenvoranschlag, die Einzelheiten und den Lieferplan und unterzeichnen Sie dann den Vertrag.

Produktion

Produktionsprozess organisieren, Programmierung und Bearbeitung starten.

Qualitätskontrolle

Strenge Qualitätskontrolle während der Produktion und der Endkontrolle.

Verpackung und Versand

Verpacken Sie die Teile, bringen Sie Etiketten zur Identifizierung der Teile an, und beginnen Sie mit dem Versand.

RFQ 222 senden

Rezension & Zitat

Bestellung bestätigen

Produktion

QC

Lieferung

FAQ

Spritzgießen FAQs zum Kauf

Genaues Angebot einholen Für Ihre nächsten Projekte

Ganz gleich, ob Ihr Projekt kompliziert oder einfach ist, ob es sich um Metall oder Kunststoff handelt, Sie erhalten innerhalb von 6 Stunden ein genaues Angebot.

Heute ein Angebot einholenSpritzgießen Einblicke

Was ist Spritzgießen?

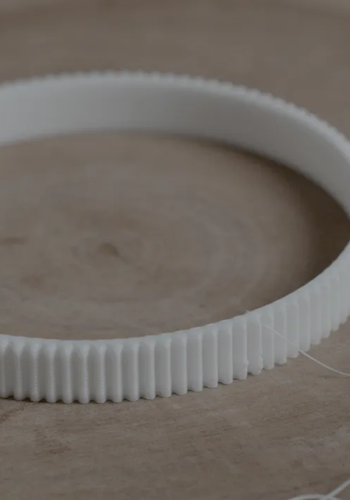

Injection molding is a manufacturing process used to create parts by injecting molten plastic into a mold. The mold is typically made from metal and designed to form the desired shape of the final product.

Once the plastic cools and solidifies, the mold opens, and the part is ejected. The process is fast, repeatable, and highly efficient for making large volumes of identical products. You start by choosing a suitable plastic, then the mold is closed, filled, cooled, and the part is released. If you need consistent, durable, and well-finished plastic parts with tight tolerances, injection molding is often the best solution to meet your production goals.

If you’ve moved past prototyping and are ready to scale your production, injection molding is likely the next step.

What are the Advantages of Injection Molding?

Injection molding offers reliable and efficient production with consistent quality, especially when you're creating parts in large volumes. It combines speed, precision, and material variety to deliver durable plastic components with clean finishes.

- Fast production cycles

- Consistent high-quality part

- Cost-effective production method

- Supports complex geometries

- High material flexibility

- Minimale Abfallerzeugung

When Do You Use Injection Molding?

In der Automobilbranche wird es zur Herstellung von Innenelementen wie Armaturenbrettern und Außenteilen wie Stoßfängern verwendet. Die Unterhaltungselektronikindustrie profitiert vom Spritzgießen bei der Herstellung von Gerätegehäusen und komplizierten elektronischen Komponenten.

Im medizinischen Bereich wird das Verfahren zur Herstellung von Komponenten für medizinische Geräte und Präzisionsteilen für Diagnosegeräte eingesetzt. Bei Verpackungsanwendungen werden Kunststoffbehälter, Verschlüsse und Verpackungseinsätze hergestellt.

Its usage extends to appliances, construction materials, sporting goods, and household items, manufacturing diverse products with complex designs, precision, and consistency in large volumes.