- Startseite

- Ressourcen

- CNC Machining Copper: Techniques, Grades, Applications

CNC Machining Copper: Techniques, Grades, Applications

CNC machining copper is one of my favorite ways to make precise parts quickly and reliably. In this blog, I’ll share my experience and insights about CNC machining copper, such as the different grades, machining techniques, and real-world applications.

What is Copper Machining?

CNC machines work with great accuracy and can handle many types of materials. Before CNC technology, machining copper was difficult and time-consuming. But now, it’s much easier and more efficient.

CNC machining is an automated process where the machine follows programmed instructions to move the cutting tool and remove material from the copper workpiece. Because of this, I can shape copper parts exactly as needed with tight tolerances and excellent precision.

Why Use Copper for CNC Machining?

- Copper conducts electricity very well, so it is perfect for electrical parts and components that need excellent electrical flow.

- It also transfers heat efficiently, which is why it is great for parts that need good heat control, like heat exchanges or automotive brake components.

- Copper doesn’t rust easily. It works well in plumbing, HVAC systems, and other environments where moisture is present.

- Since copper is soft and ductile, it is easy to cut and shape using CNC machines. This helps me create precise and detailed parts with consistent quality.

- Copper is usually cheaper than metals like stainless steel or aluminum, which helps keep production costs low.

- Copper can be reused again and again without losing its quality, so it is an environmentally friendly material for CNC machining.

Common Techniques for CNC Machining Copper

CNC-Fräsen

I use rotating cutting tools to remove material from copper. It is very precise and works well for detailed or complex parts.

CNC-Drehen

Unter CNC-Drehen, the copper workpiece spins while a cutting tool shapes it. I use this technique for round or cylindrical parts, as it can handle both inside and outside surfaces.

Bohren

I use drilling to make clean, round holes in copper. I use this when parts need to be fastened or bolted together.

Anzapfen

It creates threads inside the drilled holes so screws or bolts can fit properly. I can do this manually, but for better accuracy, using a CNC machine is much more preferable.

Schleifen

This gives the part a smooth finish and precise dimensions. I usually do this after milling or turning to refine the surface.

Elektrische Funkenerosion (EDM)

When I need very fine detail or tight tolerances, I use EDM. It shapes copper using controlled electrical sparks, so it is ideal for complex designs.

Wasserstrahlschneiden

Water jet cutting uses a powerful stream of water, sometimes mixed with abrasive material, to cut copper sheets. I use this for thick copper pieces because it doesn’t cause heat distortion.

Different Grades of Copper Used in CNC Machining

Reines Kupfer

This is soft and easy to shape. Small amounts of other elements can be added to improve its strength or toughness, but it still keeps its great electrical and thermal conductivity. Commercially pure copper usually has about 0.7% impurities and is labeled between C10100 and C13000.

Elektrolytisches Kupfer

Electrolytic copper comes from refining cathode copper, which is 99.95% pure. It is made through an electrolysis process that removes most impurities. The most common type is C11000, which has extremely low impurity levels with less than 50 parts per million.

This copper grade offers nearly 100% conductivity on the International Annealed Copper Standard (IACS) scale and has excellent ductility. I like using electrolytic copper for electrical applications such as busbars, windings, and cable.

Sauerstofffreies Kupfer

This grade has the highest purity and contains almost no oxygen. Because of its excellent electrical conductivity, I often use it for parts that need very clean and reliable electrical performance, such as high-vacuum electronic components.

These are the two main types of oxygen-free copper:

C10100 (Oxygen-Free Electronic or OFE): This type has about 0.0005% oxygen and is very pure. It is more expensive but gives top-quality performance.

C10200 (Oxygen-Free or OF): this one has around 0.001% oxygen and offers 100% conductivity, the same as electrolytic copper.

Oxygen-free copper is made by melting high-quality cathode copper in an environment with no oxygen, usually under a graphite cover. This process prevents oxidation and keeps the copper extremely clean.

Freiflächenbearbeitung von Kupfer

Free-machining copper contains small amounts of metals like zinc, nickel, phosphorus, and tin. These elements make it easier to machine while still keeping good strength and corrosion resistance.

Brass and bronze are common types of free-machining copper alloys. Brass, made of copper and zinc, is easy to machine and doesn’t rust easily. Bronze is made of copper, tin, and phosphorus, is tougher, and has great impact strength.

I often use free-machining copper for parts that need detailed cutting and shaping, such as gears, coins, hydraulic components, torches, and electrical connectors.

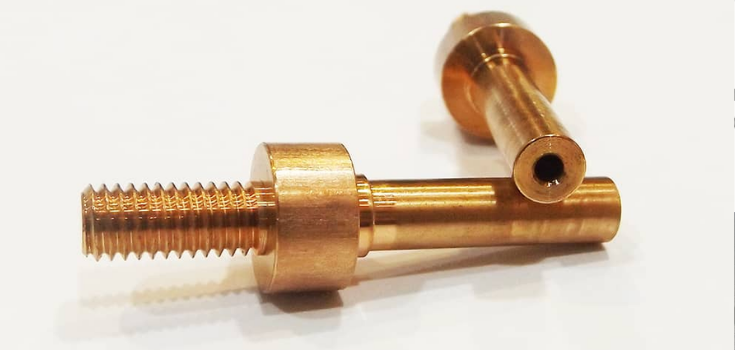

Tellurium Copper (C14500)

I like working with tellurium copper because it keeps most of copper’s electrical conductivity but machines much more easily. The tellurium helps make clean chips, so tools last longer and the cut stays smooth. It also resists corrosion, which makes it great for different environments.

I often use it for electrical parts, switchgear, and welding jobs. It is perfect when I need both accuracy and good machinability. With sharp tools and high speeds, it stays precise and consistent.

Beryllium Copper (C17200, C17500)

Beryllium-Kupfer is strong, resists wear, and keeps its shape under stress. It handles repeated use well and is safe for explosive areas because it doesn’t spark.

I use it for aerospace parts, springs, and non-sparking tools. Machining it needs care, so good ventilation, coolants, and protective gear keep me safe and tools lasting longer.

Comparison Table of Copper Materials

| Material | Stärke | Electrical Conductivity (%IACS) | Bearbeitbarkeit | Korrosionsbeständigkeit | Application Type |

| Pure Copper (C10100 - C13000) | Niedrig | Sehr hoch | Schlecht | Hoch | Electrical, Thermal |

| Electrolytic Copper (C11000) | Low - Moderate | Sehr hoch | Schlecht | Hoch | Busbars, Windings, Cables |

| Oxygen-Free Copper (C10100/ C10200) | Low - Moderate | Sehr hoch | Schlecht | Hoch | High-vacuum Components, Electronics |

| Free-Machining Copper (Brass) | Mäßig | Mittel | Ausgezeichnet | Mäßig | Fittings, Valves, Connectors |

| Free-Machining Copper (Bronze) | Hoch | Mittel | Mäßig | Hoch | Bearings, Pumps, Gears |

| Tellurium Copper (C14500) | Mäßig | Hoch | Sehr gut | Hoch | Electrical Components, Switchgear, Welding |

| Beryllium Copper (C17200/ C17500) | Sehr hoch | Mittel | Mäßig | Hoch | Aerospace, Springs, Non-sparking Tools |

Surface Finishes Available for Machined Copper Parts

After machining, I often apply surface finishes to copper parts to improve their appearance and performance. Here are some common finishes I use:

Media Blasting

I use this to smooth out any machining marks or defects on copper parts. It gives the surface a subtle, matte look and makes it more durable.

Galvanik

I electroplate copper parts when I need to add a protective layer to them, as it prevents oxidation and extends their lifespan. I like this method because it does not affect copper’s electrical and thermal conductivity.

Elektropolieren

This method removes a very thin layer of material from the copper surface, usually between 0.0025mm and 0.0635mm. This makes the surface smoother, shinier, and more resistant to corrosion, giving the part a clean, professional finish.

Copper vs Other Metals in CNC Machining

I often compare copper to other metals when deciding what to machine. Here’s a simple comparison of metals I usually consider:

| Metall | Stärke | Leitfähigkeit | Bearbeitbarkeit | Korrosionsbeständigkeit |

| Kupfer | Niedrig | Sehr hoch | Mäßig | Hoch |

| Aluminium | Niedrig | Hoch | Ausgezeichnet | Mäßig |

| CNC Steel | Hoch | Niedrig | Mäßig | Moderate - High |

| CNC Stainless | Sehr hoch | Niedrig | Difficult | Sehr hoch |

| Messing | Mäßig | Mittel | Ausgezeichnet | Mäßig |

Challenges of CNC Machining Copper

- Some copper grades cannot be used with certain processes, like coated metal arc welding or spot welding.

- Depending on the grade, copper can corrode when exposed to reactive substances, so I always consider the environment where the part will be used.

Precision and Key Factors in CNC Machining Copper

Getting high precision and maintaining tight tolerances is crucial when machining copper. From my experience, several factors have a big impact on the results:

- A well-calibrated, stable machine ensures consistent accuracy.

- Different grades affect machinability, part strength, and electrical conductivity, so choosing the right one is the first step.

- Using the right tools and balancing cutting speed and feed helps reduce wear and achieve a smooth finish.

- I optimize parts design to take advantage of copper’s properties while keeping them easy to machine efficiently.

- Knowing how the material behaves and adjusting the process on the fly makes a huge difference.

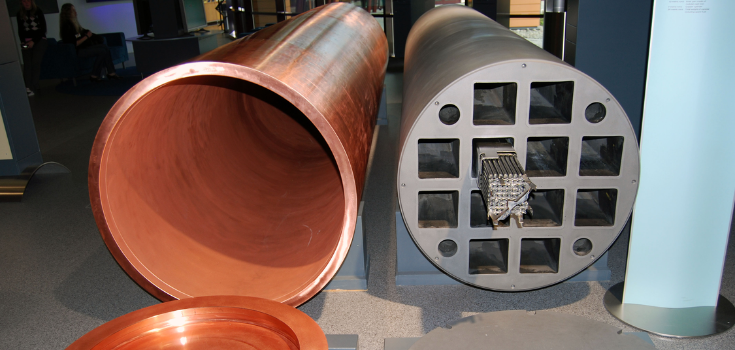

Applications of Copper Machining

Bauwesen

Copper looks great and lasts a long time, so it is perfect for construction. I’ve machined copper for roofing, gutters, rainwater downspouts, and wall cladding. Copper pipes are also popular in heating systems because they resist corrosion.

Elektronik

Copper conducts electricity well, so I use CNC machining to make electrical wiring, components, generators, transformers, and even PCBs for various devices.

Automobilindustrie

The automotive industry uses CNC-machined copper for many vehicle parts. Radiators, coolers, and electric motor components are made from copper because of its excellent conductivity. CNC machining allows me to create complex shapes needed for these parts.

Münzindustrie

Copper has been used for coins for many years. Its durability and malleability make it easy to stamp coins, and its corrosion resistance and antimicrobial properties help them last longer in circulation.

Precision CNC Machining Services at DEK

At DEK, we provide high-precision CNC machining copper services with strict quality control. Whether it is copper CNC milling or turning, our team ensures accuracy, smooth finishes, and fast delivery. Contact us today to get a free quote.

Schlussfolgerung

CNC machining copper needs the right care and approach. By using the right grade, tools, and techniques, I can make precise, high-quality parts. From electrical components to automotive and construction pieces, copper’s conductivity and durability make it versatile. Done right, CNC machining copper always delivers reliable results.

FAQs

What is the best tool to machine copper?

I look for tools that are durable, like carbide or HSS, sharp and well-designed for tight cuts, and fully compatible with our CNC machines to get the best results.

Is copper easy to machine?

Machining pure copper can be difficult because it is very soft and can stick to the cutting tool. Copper alloys, with small amounts of added elements, are easier to machine and hold their shape better during cutting.

What is the best copper for CNC machining?

C101 copper has very high purity and excellent conductivity, which is why it is great for electrical parts. C110 copper, on the other hand, is easier to machine and more cost-effective, so it is ideal for many CNC applications.