NC machining was the first main step toward automating metalworking, long before computer-driven CNC machines became the standard. By using coded instructions on punched tape or cards, NC systems authorized creators create exact and repeatable parts without continuous manual input.

In this blog, you will learn about what NC machining is, how NC works, its full process, machine and system types, applications, advantages, limitations, and a clear NC vs CNC comparison to help you choose the right path.

What is NC Machining?

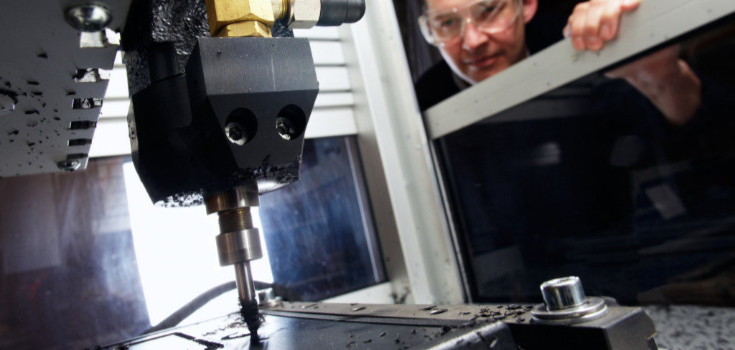

NC Machining refers to a type of automation that can be applied to a variety of machine tools, and the methods and technology used were designed for a far more accurate and precise development.

The machine is controlled by codes that were pre-programmed into the machine, G-code and M-code that define the cutting speed and feed rate of the tool.

Compared with ordinary machining, NC Code Machining reduces human error. The same batch of parts has higher dimensional accuracy.

How Does NC Machining Work?

NC machining relies on pre-programmed instructions encoded into punched tape. The punched tape is a series of codes that is used for controlling the machine tool path, and these codes are read by sensors, converting punched holes into electrical signals, which are processed in the Machine Control Unit (MCU).

MCU processes these input signals and relays them to the machine's drive system. Following receipt of instructions, the machine commands the tool along the programmed path to perform operations such as milling, drilling, or cutting.

Creating the Part: An idea for the part starts with a computer-aided design (CAD).

Translation to Code: The design is converted into NC code. Also, known as G-code, which the machine can read.

Machine Setup: The workpiece, metal or plastic, etc, is well positioned in the machine, and tools are set up.

Machining Process: The machine executes the code, usually by cutting, drilling, turning, or milling the material into the shapes needed.

Окончательная проверка: When complete, the part is measured for accuracy and quality.

What is the NC Machining Process?

The NC machining process is a method used to automate machine tools by the use of computers. This process involves a series of stages to confirm that the final product meets accurate requirements, starting from design preparation all the way to inspection. Below are the main stages required in the NC machining process:

Design preparation: Define geometry, datums, tolerances, surface finish, and material.

Программирование: Create a sequence of moves. The program specifies tool numbers, spindle, feed, coolant, approach/clearance, and safe retracts.

Data input: Load the program. Verify the checksum or do a dry run without cutting.

Setup: Locate the workpiece using supports, set work offsets and tool lengths, select holders, and confirm holding and clearance.

Execution: The MCU adjusts moves, commands alignment drives and spindle, and steps through operations.

Осмотр: Check critical features, verify tolerances, and record results. Adjust speeds if required.

What Materials Can Be Machined Using NC Machining?

| Материал | Свойства | Suitability for NC Machining |

| Алюминий | Lightweight, corrosion-resistant | Aerospace structures, housings |

| Сталь | Strong, stable | Shafts, fixtures, tooling |

| Латунь | Free-cutting, conductive | Fittings, connectors, valves |

| Титан | High strength/weight, tough cut | Implants, aerospace hardware |

| Plastics (ABS, Nylon, Acrylic) | Light, low melting temp | Consumer parts, prototypes |

| Медь | Very conductive, gummy | Bus bars, terminals |

| Композиты | Abrasive fibers, low weight | Panels, brackets, fairings |

Advantages of NC Machining

Высокая точность и согласованность

You get closely controlled limits batch after batch. The program controls motion paths and feeds, reducing differences from manual skill.

Reduced Lead Time & Set-Up Time

Set-up is good, and fewer fixtures are needed. Since positioning is controlled by the machine program, not complex fixtures, it speeds your time-to-market.

Higher Production Rates & Lower Non‑Productive Time

Automatic tool changers and fewer manual steps reduce idle time. Your machines can run longer with limited human involvement.

Labor Costs & Skill Requirements

You do not need highly skilled technicians. Operators manage the program and manage multiple machines, releasing skilled engineers for process planning.

Consistent Quality & Reduced Scrap

Every machined part follows the same program. Consistency improves quality and cuts inspection needs, and fewer errors mean less unused material.

Broader Material & Operation Versatility

You can machine various металлы, пластмассы, and mixtures using milling, turning, drilling, and more. One machine matches multiple job types.

Improved Safety

Operators stay away from moving parts. Built-in features and automated operation reduce hands‑on risk.

Data Archiving & Optimization

Programs, cutting paths, and parameters are installed digitally. These allow repeat runs, toolpath optimization, and process analysis.

Limitations of NC Machining

High Initial Cost: NC machines require a heavy investment in purchase and setup.

Skilled Operators Needed: Must have experience with programming and handling.

Complex Maintenance: Servicing and repairs are expensive and time-consuming.

Limited Flexibility: Not suitable when regular design changes are needed.

Dependency on Programs: Any coding error directly impacts product quality and accuracy.

Not Ideal for Small Batches: More cost-effective for mass production than small production.

Different Types of NC Machines

NC Milling Machine

An NC milling machine is one of the most commonly used NC machines in manufacturing industries. An NC milling machine uses programming instructions to move the cutting tool along different rotations to remove material from the component.

This type of machine is highly optimized for producing advanced shapes, slots, and holes with high accuracy.

NC Lathes

NC lathes are created for machining cylindrical or round objects. The workpiece rotates while the cutting tool remains stationary and follows the programming. These machines are especially useful for creating shafts, pipes, and bushings.

NC Press Brake

An NC press brake is commonly used in sheet metal fabrication for bending operations. It works using numerical control commands to position the metal sheet accurately, ensuring constant bends and angles.

NC Grinder

NC grinders are customized machines designed for the precision finishing of components. These machines are most commonly used with abrasive wheels and programmed instructions to achieve extremely fine surface finishes.

NC Router

An NC router is used for cutting and shaping soft materials such as wood, plastics, composites, and even some metals. These machines are useful in furniture manufacturing and mold-making industries due to their ability to produce patterns and designs quickly and efficiently.

Different Types of NC Systems

Point-to-Point (PTP) Systems

Point-to-Point systems are among the simplest types of NC systems. In this method, the tool moves from one fixed point to another without cutting in between. The machining operation, such as drilling or punching, only occurs at specific points. PTP systems are easy to program and ideal for tasks like drilling a hole.

Contouring Systems

Contouring systems allow for continuous tool movement along multiple axes. Unlike PTP systems, these can perform machining while the tool is in motion, which is why they are suitable for complex shapes, curves, and 3D profiles.

Closed-Loop Systems

Closed-loop systems depend on feedback devices such as encoders and sensors to monitor and correct the machine’s position and movement constantly. This confirms high accuracy and precision, even in complex machining operations.

Open-Loop Systems

Open-loop systems operate without feedback devices. The machine executes instructions without checking if the commands were accurately followed. They are less accurate compared to closed-loop systems, but they are simpler, more cost-effective, and suitable for applications where extreme accuracy is not critical.

Specific Applications of NC Machining

Аэрокосмическая промышленность: airframe components, structural brackets, turbine blades

Defense: Components of military vehicles, weapon parts

Автомобили: Chassis parts, transmission gears, engine blocks

Медицина: Orthopedic implants, dental fixtures, surgical instruments

Энергия: Wind turbine and valve parts, pump impellers

Электроника: Heat sinks, connectors, housings

What Software is Used in NC Machining?

Here are some important software that are used in NC machining:

- CAD Software

- CAM Software

- Tool Management Software

- Quality Control Software

- Production Planning Software

Common Problems and Defects with NC Machining

Here are the most commonly faced problems that occur in NC machining:

- Tool wear/chatter

- Dimensional drift

- Misalignment/stack-up.

- Programming errors

- Burrs/roughness

- Overheating/melting (plastics)

NC vs CNC Machining

| Характеристика | NC Machining | Обработка с ЧПУ |

| Control Input | Punched basic codes | Digital programs via CAD/CAM & editors |

| Гибкость | Low changes need for new edits | High quick edits, tool libraries. |

| Точность | Moderate, often open-loop | Very high closed-loop, compensation |

| Setup Time | Longer manual verification | Shorter presets, offsets, stored setups |

| Monitoring | Minimal | Alarms, logs, real-time loads/temps/vibration |

| Production Speed | Good for repetitive PTP | Faster overall adaptive feeds, high-speed milling |

| Typical Use | Simple drilling, turning, and forming | Complex 3D parts, multi-op cells, tight tolerances |

Заключение

The evolution of NC machining from manual labor to reliable automation for repeating parts is an industry story. NC provides simple and fixed operations, especially when cost and consistency tend to win.

If you need more limited tolerances, faster changeovers, or complex geometry, DEK can provide precision machining with advanced capability and strict quality control. Request a quote today and confidently turn your drawings into production parts.

Вопросы и ответы

How much does NC machining cost?

Budgets are split into machine/setup and per-part. Legacy NC machines (often second-hand) can be far cheaper than CNC. However, expect a higher setup time. For parts, cost depends on material, tolerances, cycle time, tooling, and batch size. As a rule, simple hole patterns/turning on NC are economical in medium-to-large batches, while complex shapes are usually cheaper on CNC.

What tools are required for NC machining?

Cutting tools (drills, end mills, reamers, inserts), rigid holders/collets, vises/fixtures/jigs and locators, probing or edge-finders, coolant/mist systems, deburring tools, and inspection gear (micrometers, calipers, plug gauges, surface plates). For tape-based shops: a tape punch/reader and basic verification utilities.

What are the key components of an NC Machine?

There are a few key components of an NC Machine, such as the input device, the Machine Control Unit (MCU), the drive system, and the machine tool