Blind holes are common in many components. You’ll use them when you need threads, fasteners, or other features that shouldn’t be visible from the outside.

Let me show you what is a blind hole in engineering, how to drill it, and what to keep in mind.

Callout Symbol of a Blind Hole

When you see a circle with a line going halfway into it, that means it’s a blind hole. This tells you the hole doesn’t go all the way through the material. You’ll need to drill or tap it carefully to the right depth.

If you see “M20 x 2.5,” that tells you the size of the fastener and how far apart the threads are. A downward arrow (↧) shows how deep you need to tap the threads. The last number tells you how deep the whole hole should be.

What is a Blind Hole in Engineering and Machining?

A blind hole is a hole you drill, ream, or mill into a material, but it doesn’t go all the way through. It stops at a certain depth, so the bottom is closed. You can use it to hold screws, dowels, or other parts without them going through the other side.

You’ll often use blind holes in металл or wood projects when you want a tight fit or a cleaner look. They help hide screws or parts and make the final product look better. Blind holes are also great when you need strong, detailed parts for jobs that require high precision.

How to Drill a Blind Hole

Follow these steps to do it safely and accurately:

- Start by clamping your material so it doesn’t move. Mark the center of the hole with a sharp tool to guide the drill bit.

- Choose the right size drill bit, insert it into the drill, and tighten it.

- Mark the needed depth on the bit using tape or a marker. Place the drill on your mark and start slowly.

- Press down gently and drill steadily. Stop now and then to check the depth.

- Pull the drill out occasionally to clear out chips. You can use air or a brush to clean the hole.

- Once you reach the tape mark, stop drilling. Check the hole’s size and depth, and clean up any rough edges if needed.

Pros and Cons of Blind Holes

Here are the main advantages of blind holes:

- Hides screws for a cleaner design.

- Spreads stress and helps parts last longer.

- Great for small or lightweight products, like in electronics or aerospace.

And here are some of the downsides:

- Dirt can get stuck since the hole doesn’t go through.

- Making screw threads is tougher and needs precision.

- Soft materials may bend under heat or pressure.

How to Clean Blind Holes

When you’re drilling blind holes, you need to clean out the chips. If you don’t, they can cause problems like wearing out the drill faster or even breaking it.

While бурение, you can use a strong stream of coolant or air to push the chips out of the hole. If the hole gets too deep, the drill flutes can’t remove the chips very well.

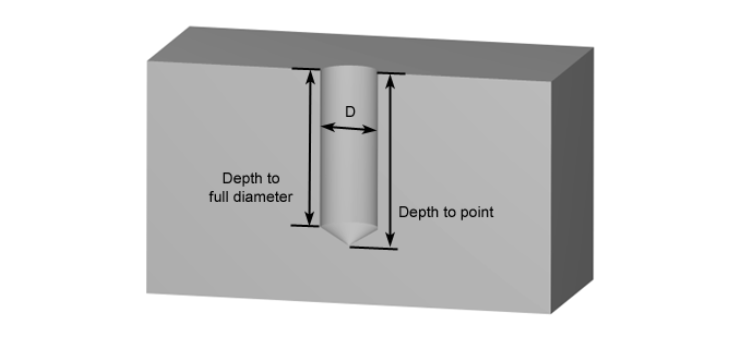

Drill Depth Clearance in Blind Holes

When you drill a blind hole, make sure it’s deep enough for the tap to cut all the threads and still have room at the bottom. This helps the screw hold tight and protects the tap.

For example, if you’re using a taper tap, you’ll need to drill deeper. That’s because it has a long point before it can cut full threads. Bottom taps and spiral flute taps don’t need as much depth since they start cutting full threads sooner.

You can use these simple formulas to help figure out how deep to drill:

If hole depth = 2 x fastener’s diameter:

Thread Depth + (Thread Pitch * 9)

For other holes:

(Thread Depth + (1 + Thread Pitch * 4)) + (Thread Pitch * 5)

Other Machining Processes for Blind Holes

Drilling is the most common way to make blind holes, but it’s not the only option. You can also use boring, milling, or reaming. Here’s a quick look at each one:

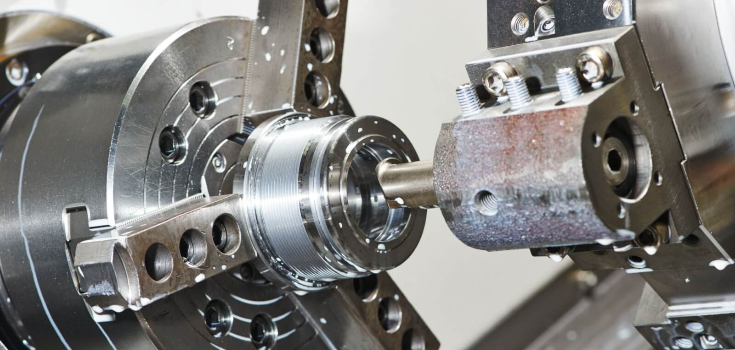

Скука

Use boring when you need a big hole that has to be very exact. You start with a hole and make it larger using a boring machine.

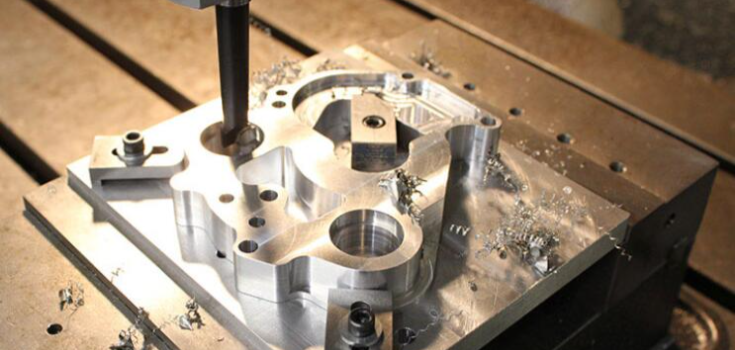

Фрезерование

Milling works well for holes that are too big for drilling or for holes that are not round, like slots or rectangles.

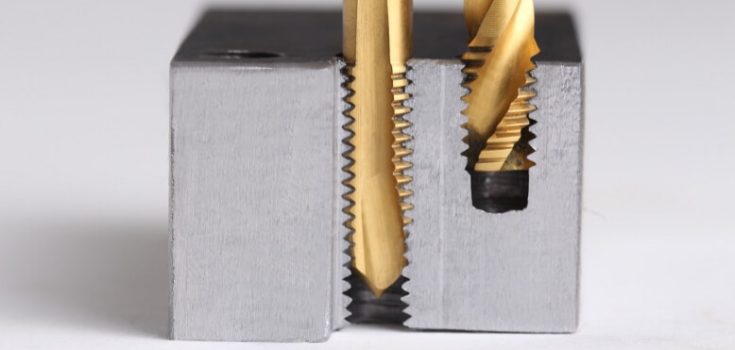

Развертка

Reaming makes a hole just a little bit bigger. You use it when you want a smoother finish or better accuracy on a hole you’ve already made.

Tips and Design Considerations for Drilling the Perfect Blind Hole

Here are some easy tips to help you drill holes correctly:

- You should choose a drill bit that matches the material you’re working with. For most metals, using a high-speed steel bit works well for making threads.

- Also, make sure the tap size matches the thread size you want. If the hole is shallow or deep, choose from a plug tap, taper tap, or bottoming tap.

- Always measure how deep the hole should be before you start. Mark the depth on your drill bit, so you don’t go too far. Drilling too deep can weaken the part or cause it to break.

- You can also use a depth collar or depth stop on your drill to help control this. Double-check the depth and make sure it matches your design or plan.

- Before you drill, use layout tools like a square and center punch to mark exactly where the hole should go. Make sure the hole is pointed in the right direction and at the right angle. This helps the finished part fit and work the way it’s supposed to.

- The size of the hole will tell you what drill bit to use. You can look at a drill bit chart to find the right size. Before drilling your final piece, try the drill bit on some scrap material to make sure it’s the right fit.

- Different materials need different drilling settings. You should know how the materials you’re using affect the way you drill the blind hole.

- Use cutting fluid or oil to keep the drill cool and reduce friction while you work. After drilling, use a brush or compressed air to clear out any chips or dust. Before you tap threads into the hole, make sure it’s clean and clear.

Engineering Applications of Blind Holes

Blind holes are helpful in many ways. Here’s where you might use them:

- If you work in aircraft manufacturing, you can use blind holes to make parts lighter without losing strength.

- When you’re building circuit boards, you can use blind holes to mount things like connectors and spacers. They help hold things in place without messing up the other side of the board.

- In metal or wood projects, you can use blind holes to make your designs look good. Fill them with different materials like colored resin or metal to add style.

- If you’re working with molds for things like injection molding or casting, blind holes help you set up cooling channels, ejector pins, and alignment parts.

- If you’re making car parts, you can use blind holes in engine blocks or transmissions to attach parts securely and save on material.

Blind Hole vs Through Hole

A through hole goes all the way through the material, with open ends on both sides. You can see through it from one side to the other. A blind hole, on the other hand, only has one open end, and the hole stops before it reaches the other side.

Through holes are easier to make because you don’t have to worry about stopping at a certain depth. You just drill all the way through. You can use either type of hole for fastening with bolts or screws, or leave them unthreaded for pins.

When you need to thread a hole, you use different tools. For blind holes, a bottoming tap is used to create threads at the bottom. For through holes, a taper tap is used to create threads.

Other Types of Holes in Engineering and Machining

Besides blind and through holes, here are some other types of holes you might encounter in machining:

Simple Hole: This is the most common type. It’s straight, cylindrical, and has the same diameter all the way through. These holes are great for assembly, clearance, and positioning.

Reamed Hole: This hole is smoothed and sized precisely using a tool called a reamer. This gives it a smooth finish and exact diameter.

Countersunk Hole: This type of hole is cone-shaped and created to make a screw or bolt head sit flush with the surface. It helps prevent screws or bolts from sticking out.

Counterbore: A counterbore is a flat-bottomed hole that’s larger and deeper than the original hole. It’s drilled to create a flat surface around the hole to fit the head of a screw or bolt.

Tapped Hole: This has threads cut into it with a tool called a tap. This lets screws or bolts securely fit into the hole.

Коническое отверстие: A tapered hole gradually changes in diameter from one end to the other. It’s used in situations like press-fit joints, where it helps hold two parts together tightly.

Заключение

Blind holes make parts stronger, reduce material waste, improve the look of surfaces, and hold fasteners.

For all your machining needs, check out DEK’s CNC machining services, including precise blind hole machining. We offer a wide range of materials and finishes to meet your needs! Upload a part for a free quote today.