Before you treat nylon and polyamide as equals, let me prove to you that they are not so identical. Нейлон is a specific category under aliphatic polyamide, while полиамид has a much more extensive connotation. It also refers to aromatic and semi-aromatic polymers. Both terms find use in industries with their consideration of strength, wear resistance, and flexibility.

In this blog, you will learn about types, uses, methods of identification, common properties, and advice on how to select between Polyamide vs Nylon for CNC machining or any other manufacturing process.

What are Polyamides?

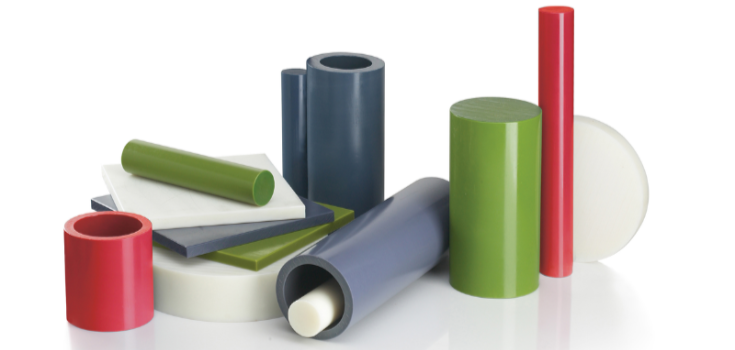

Polyamides are polymers formed by repeating amide bonds (–CO–NH–) along their backbone. These amide bonds give them strength, chemical resistance, and the ability to be processed into fibers, films, or solid parts. Polyamides can be either natural (silk or wool) or synthetic (for automotive and aerospace).

The properties of polyamides are greatly inspired by molecular structure, ranging from flexible aliphatic chains to rigid aromatic rings.

Types of Polyamides

Polyamides are typically divided into several types. It is based on their chemical structure and performance.

| Type of Polyamide | Raw Material | Key Features & Uses |

| Natural Polyamides | Wool, Silk, Collagen, Keratin | Natural Polyamides are commonly used in the textile, rope, and natural fabric industries due to their softness, flexibility. |

| Aliphatic Polyamides | Nylon 6, Nylon 6/6 | Aliphatic Polyamides have a good understanding of toughness, machinability, and processability. It is acceptable for various engineering components and general applications. |

| Aromatic Polyamides | Kevlar, Nomex | Aromatic Polyamides have great tensile strength, excellent heat resistance. It is also used in ballistic armor, fire-resistant clothing, and aerospace applications. |

| Semi-Aromatic Polyamides | Zytel, Rilsan | Semi-Aromatic Polyamides have great high-temperature resistance, chemical stability, and good structural reliability in rough environments. |

Applications of Polyamides

Polyamides are used in industries ranging from textiles to engineering plastics. Below are the examples of how different industries depend on polyamides for specific high-performance applications:

| Промышленность | Общие приложения |

| Автомобили | Fuel lines, under-the-hood components, and airbags |

| Аэрокосмическая промышленность | Lightweight components, insulation, and structural parts |

| Protective Equipment | Bulletproof vests, fire-resistant suits, and industrial gloves |

| Электроника | Cable insulation, connectors, and circuit protection |

| Industrial Manufacturing | Conveyor belts, seals, and wear-resistant parts |

Their adaptability makes them a go-to choice when both strength and chemical resistance are required.

How to Identify Polyamides

Identifying polyamides requires more than a visual check because many plastics look alike. Common methods include:

Technical Datasheets: One of the most trustworthy and reliable resources provided by manufacturers.

Melting Point Testing: Polyamides have different grades that have specific melting points (e.g., Nylon 6 at ~220°C, aramids are much higher).

Density Measurement: A small change in density can help narrow identification.

Что такое нейлон?

Nylon is a family of aliphatic polyamides first commercialized by DuPont in 1938. It was initially used for stockings and quickly expanded into engineering and industrial applications. Nylon is also known for high resistance, good toughness, and a favorable strength-to-weight ratio. It is easy to machine, easy to process, and suitable for specific performance needs.

Виды нейлона

There are several types of nylon, each with clear properties.

| Type of Nylon | Raw Material | Основные характеристики |

| Нейлон 6 | Caprolactam | Nylon 6 offers good results for resistance, hardness, and flexibility. It is easy to colour and process, making it ideal for textiles and shaped items. |

| Нейлон 6/6 | Hexamethylene diamine + Adipic acid | Nylon 6/6 is also known for higher hardness, excellent abrasion resistance, and also has a high melting point (~260°C). It is suitable for mechanical and structural uses. |

| Нейлон 11 | Castor oil | Nylon 11 is a biobased material with low moisture absorption, high chemical resistance, and great flexibility for ideal rough environments. |

| Нейлон 12 | Similar to Nylon 11 | Nylon 12 features very low water absorption, excellent dimensional stability, and is ideal for accuracy and high-performance applications. |

Применение нейлона

Nylon is widely used in industrial, consumer, and engineering applications. This table shows the key industries and the specific ways nylon is applied within them

| Промышленность | Общие приложения |

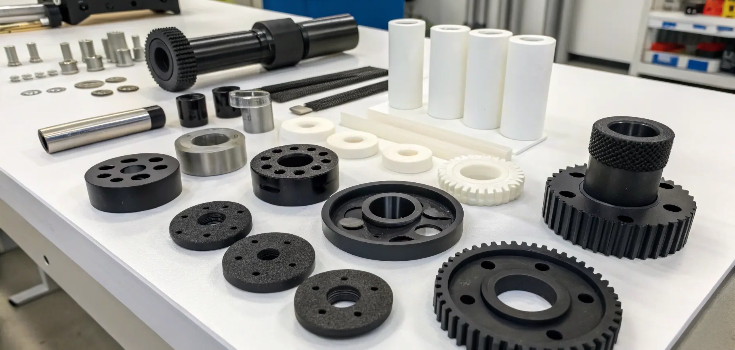

| Engineering Parts | Gears, bushings, bearings, and rollers |

| Потребительские товары | Zippers, textiles, luggage, and kitchen utensils |

| Industrial Equipment | Conveyor belts, cable ties, and fishing nets |

| Аддитивное производство | Selective Laser Sintering (SLS) and filament-based 3D printing |

How to Identify Nylon

Nylon classification is similar to polyamide classification, but with a smaller focus:

Look for Datasheets or Markings: Manufacturers often define the exact nylon grade.

Melting Point Testing: Nylons melt between 190°C and 265°C, depending on the grade.

FTIR Analysis: Confirms the aliphatic structure unique to nylon.

Water Absorption Test: Nylons absorb balanced moisture, higher than plastics but less than polyamides.

Common Properties of Polyamides and Nylon

Polyamides, including nylon, share a set of specific properties that make them valuable across all industries. Each type may differ in strength, flexibility, or thermal behavior. Their resistant and high-performance nature integrates them. Below are some of the key properties for both materials.

Высокая прочность на разрыв

Polyamides and nylon are known for their valuable ability to resist considerable mechanical load without breaking.

Good Thermal Stability

They can maintain performance under a wide range of temperatures, with some grades resisting extreme heat.

Химическая стойкость

Polyamides are highly resistant to oils, solvents, and fuels, making them ideal for automotive and industrial environments.

Lightweight and Tough

Both are lightweight and strong. These materials have found application in replacing metals in various engineering applications.

Поглощение влаги

Both materials absorb water to some extent, while also improving toughness in certain instances.

Processability

They can be easily molded, extruded, machined, or printed. Due to this, it allows many different processing technologies.

Polyamide vs Nylon: Which is Better for CNC Machining?

When you decide between polyamide and nylon for CNC machining, it is important to understand their key differences. Nylon is a specific type of aliphatic polyamide, known for its excellent workability and consistent performance.

Polyamides cover a wide range of materials, including aromatic and semi-aromatic types. It may resist heat and chemicals better. It can be harder to machine. These variants may require specific tooling or slower speeds during CNC processes.

For most CNC machining projects, nylon offers the best balance of strength and flexibility. If your application involves rough environments or high temperatures, certain polyamide types might be more suitable despite their machining challenges. Understanding your specific needs, such as mechanical load, temperature exposure, and dimensional stability, DEK will help you choose the right material for your CNC parts.

Заключение

Nylon is a member of the polyamide family, utilized due to its workability, availability, and balanced properties. If you need higher performance for heat, strength, or chemical resistance, other polyamides can fulfill those demands.

When choosing the right material for your project, consider the load and temperature conditions carefully. Always check the datasheets and, if needed, run lab tests to make sure you get the best fit for your application. DEK can help you decide which material is best, so связаться с нами сейчас и получите бесплатное предложение.

Вопросы и ответы

Does polyamide shrink?

Yes. Polyamides shrink during cooling and can change size with moisture absorption. The level of shrinkage is based on the specification and processing method.

Is Nylon more expensive than Polyamide?

Not usually. Basic Nylon is less expensive than specific polyamides like aramids or PPAs. Their pricing changes by grade and supplier.

Is Nylon a polyamide?

Yes. Nylon is a subset of the broader polyamide family, specifically aliphatic polyamides.

Can polyamide vs nylon be recycled?

Yes. Both can be mechanically or chemically reused. Mechanical recycling may reduce properties, while chemical recycling restores the base monomers.