When it comes to looking for materials to use in different applications, there is a long list; among these, the use of invar and kovar is also quite common.

If you are starting a new project and want to know about the differences between Invar vs Kovar, the guide below can help you. So, let's read.

Что такое инвар?

Invar is an alloy created by combining nickel and iron. It has 36% of nickel and has a consistent dimension over varied temperatures. The coefficient of expansion for this material is low, and it can retain toughness and strength at cryogenic temperatures.

Что такое Ковар?

Kovar is an alloy which is a combination of nickel and cobalt. It is highly compatible with borosilicate glass, which makes it suitable for multiple sealed electrical parts. It is used in metal-ceramic packages and offers excellent machinability.

Hence, creating components with tight tolerances is very easy with Kovar. It offers resistance against chemical corrosion and thermal shock.

Differences Between Invar and Kovar

The section below highlights in detail the differences between the two materials.

Invar vs Kovar: Color

Инвар is an iron and nickel alloy consisting of a silver-gray color; the color of Kovar is also silver-gray, but it is a little more on the lustrous side due to the presence of cobalt.

Invar vs Kovar: Density

The density of invar is less than Kovar, which is around 8.1 g/cm3; the density of Kovar is 8.36 g/cm3.

Invar vs Kovar: Hardness

The hardness of invar is lower, around 160 HB, and the hardness of kovar is around 210 HB.

Invar vs Kovar: Strength

The tensile strength of invar is low, amounting to 500 MPa; Kovar, on the other hand, has a high tensile strength of 700 MPa.

Invar vs Kovar: Melting Point

Ковар has a slightly higher melting point compared to Invar, being 1430 degrees Celsius. The melting point of Invar is 1425 degrees Celsius.

Invar vs Kovar: Heat-conducting Property

Invar has moderate thermal conductivity and low thermal expansion. Kovar has a low thermal conductivity but has a thermal expansion that matches ceramics or glass.

Invar vs. Kovar Electrical Conductivity

The electrical conductivity of invar is low because it has a high nickel content. Kovar has high electrical conductivity and is meant for specialized environments.

Invar vs Kovar: Corrosion Resistance

Invar has moderate resistance to corrosion and needs protective layers when subjected to harsh environments. Kovar, on the other hand, has better corrosion resistance because it has cobalt.

Invar vs Kovar: Magnetic Property

Kovar and Invar are both magnetic in nature, but Invar offers a higher magnetism than Kovar.

Invar vs Kovar: Weldability

Invar is a highly weldable material however, when welding it, care must be taken, and the weldability of Kovar is seamless.

Invar vs Kovar: Recyclability

Invar offers high recyclability and is used in industries where sustainability is needed. Kovar, on the other hand, is also highly recyclable, but it is not reused commonly.

Invar vs Kovar: Cost

Invar has a simple composition and, therefore, is affordable; Kovar is expensive because it has cobalt in its composition.

Quick Comparison Chart of Invar and Kovar

A quick table below features the comparison between Kovar and Invar at a glance.

| Свойства | Ковар | Инвар |

| Состав | Iron, nickel and cobalt | Iron and nickel |

| Прочность | Высокая прочность на разрыв | Moderate tensile strength |

| Устойчивость к коррозии | Умеренный | Умеренный |

| Магнит | Магнит | Highly magnetic |

| Свариваемость | Превосходно | Хорошо |

How to Distinguish Invar and Kovar?

Invar and Kovar are differentiated by their composition and properties. Invar is an alloy of iron and nickel and has a low thermal expansion coefficient. It is selected for applications that need dimensional stability when temperature fluctuations occur.

Kovar, on the other hand, has железо, nickel, and cobalt and it can match the thermal expansion of керамика and glass. It is used in sealing electrical applications. It has a high hardness and strength and improved weldability.

The magnetism in Invar is high compared to Kovar.

Advantages and Disadvantages of Invar vs Kovar

The advantages and disadvantages of Kovar and Invar are as follows:

Инвар

Преимущества

- It has a high stability under the varied temperature range.

- The magnetic properties of invar are also high.

- Invar is less expensive due to its simple composition.

- It is suitable for joining processes.

Недостатки

- The tensile strength of Invar is lower than Kovar and is not suitable for load-bearing applications.

- It has moderate corrosion resistance and needs protective layers in harsh surroundings.

- The electrical conductivity of Invar is low, which makes it unsuitable for electrical applications.

Ковар

Преимущества

- The thermal expansion of Kovar is similar to that of ceramics and glass.

- It offers high hardness and toughness for applications that are mechanically demanding.

- The corrosion resistance of Kovar is better than that of Invar.

Недостатки

- Kovar is more expensive than Invar as it contains cobalt.

- It is heavier than Invar, which makes it unstable for weight-sensitive applications.

- The magnetic properties of Kovar are limited.

Applications of Invar and Kovar

Invar and Kovar have various applications, and they can be used in similar industries for different products. There are many applications for these two, which are given below.

Аэрокосмическая и авиационная промышленность

Invar: It is used for manufacturing structural parts in applications that do not have stable temperatures. These are used in gyroscopes and satellite structures.

Kovar: Kovar is used to manufacture parts for extreme environments. The aerospace parts made using Kovar are avionics, sensor packages, and radar systems.

Электроника

Invar: Invar is used in the packaging of ICs and other microelectronic parts.

Kovar: It is used in semiconductor packaging and integrated circuits; it helps to produce connectors and other electronics.

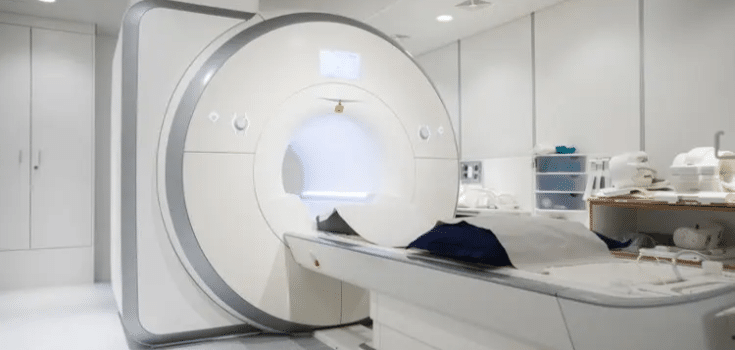

Медицина

Invar: The material invar has various properties that are unique, and hence it is suitable for medical applications that need stability and precision. It is used in MRI and CT scan machines.

Kovar: Kovar is used to manufacture housing and medical equipment.

DEK - Your Reliable Partner for Invar or Kovar Parts

Invar and Kovar parts are manufactured for a wide range of applications. We at DEK help manufacture unique and custom parts for your applications that can be designed with precision and accuracy.

So, get in touch with us if you have a new project that involves Kovar and Invar machining for parts.

Заключение

When selecting between Kovar and Invar, you need to identify the suitability of each type of material for the application based on their relevance. The guide above must have given you a detailed comparison of the two materials and their differences.