Understanding how to calculate 5 axis CNC machining prices cost becomes important for businesses that rely on precision engineering. The blog will explain to you every factor cost, from materials to labor, ensuring the reader has a clear understanding.

Engineers, product designers, or business owners-all these professionals benefit from knowing how much they have spent on 5-axis machining to optimize production and perfectly plan budgets.

Что такое 5-осевая обработка с ЧПУ?

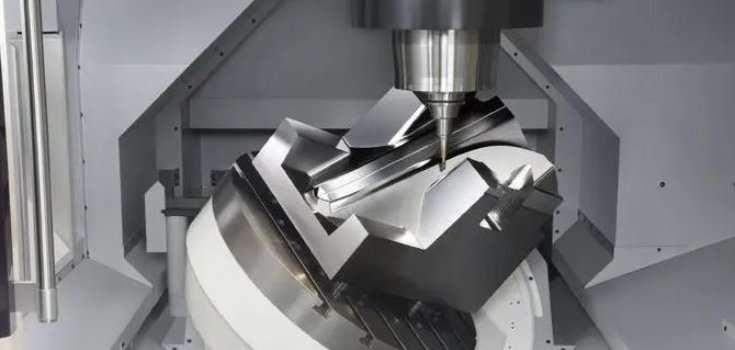

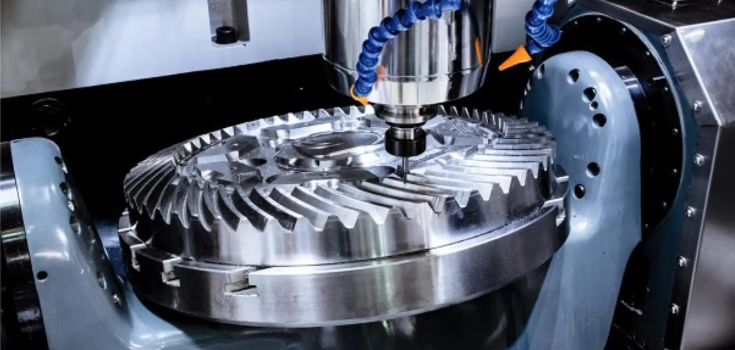

5-axis CNC machining allows you the simultaneous movement of a cutting tool across five different axes. It produces highly advanced geometries with great accuracy. Unlike traditional 3-axis machining, it decreases the number of setups, saves time, and increases accuracy. Industries such as aerospace, automotive, and medical rely heavily on 5-axis CNC to produce parts that require extremely high levels of precision.

It also avoids repositioning errors, thus creating smoother surfaces and consistent dimensions, even on difficult-to-machine materials. This technology also allows for lightweight structures, complex designs, and turbine blades. It's one of the best advantages is efficiency-making a manufacturer's output greater while maintaining precision.

How To Calculate 5 Axis CNC Machining Prices Cost

You can calculate the 5-осевая обработка costs, which are affected by various factors such as equipment type, labor, materials, complexity, and finishing. The best way of calculating would be by summing these factors to hourly machine rates, with more value-added costs such as design optimization, prototyping, and surface treatments

5 Axis CNC Machining Value and Working Costs

One needs to understand the building blocks of the cost breakdown. Those crucial aspects directly impacting how the machining rates are set include, among other things, the type of equipment and overheads. All of those must be weighed together to achieve a realistic figure.

| Фактор | Описание | Impact on Cost |

| Тип машины | High-end 5-axis machine versus entry-level | Significant |

| Labor | Salaries of skilled engineers and programmers | Moderate to High |

| Инструментальная оснастка | Cutting tools, inserts, and calibration | Умеренный |

Value of Supplies Produced by 5-axis Machines

Machined goods on 5-axis CNCs are mostly priced differently from those manufactured through conventional means. This has mainly been because of their generally higher quality finishing, more precise accuracy, and ability to meet the critical demand of industries where quality cannot be compromised.

| Продукт | Example Industries | Average Value Impact |

| Aerospace Blades | Aviation & Defense | Высокий |

| Медицинские имплантаты | Здравоохранение | Высокий |

| Автомобильные компоненты | Cars & EVs | Medium |

| Mold Tools | Производство | Medium to High |

Products made using advanced 5-axis machining typically realize a greater market value due to their precision, repeatability, and stricter quality conditions.

5-axis Engineer, Labor, and Programmer Value

Labor cost is not just about salary; it is about expertise. Programming a 5-axis machine requires skills from a highly qualified Computer-Aided Manufacturing specialist who is very precise in energy cutting strategies and can explain designs. A program can lead to scrap parts worth thousands of dollars.

In the United States, Germany, or Japan, the entry-level salary of engineers, programmers, or technicians is higher, thus increasing the overall hourly machining rates. However, in Asia, a lower cost is charged for the same work conducted. One has to be careful about the expertise and communication to address the situation. Now, this is not a matter of cost. It ensures quality, safety, and consistency.

5-axis Machining Time and Complexity

Time allocated for machine processing directly affects production costs. The more complex an object is, the longer it will take to program, set up, and cut. Typically, it takes 10-15 hours to process a pair of complex aerospace turbine blades or an orthopedic implant. A simple automotive part will typically take only about one or two hours to finish achieving the final product. More complexity means enhanced chances for tool wear and machine downtime.

So much of the planning has to be done wisely, using advanced strategies like adaptive tool paths to save time. Ultimately, machining time represents the balance between speed and precision.

Fast Prototyping and Batch Manufacturing

Actually, prototyping and production scale affect the cost in different ways. Cost per unit is higher in prototyping because for one or two parts. The setup time and machine measurement occur. For example, prototyping one medical part may cost as much as a small batch of automotive parts.

Batch manufacturing effectively shares set-up costs over many units, with a dramatic reduction of cost per part. For this reason, 5-axis machining is extremely attractive compared to others since it guarantees accuracy and scalability. For enterprises, prototype runs or mass production would depend on their current phase of product development.

Отделка поверхности

Обработка поверхности is one of the underestimated costs in cost calculations. Finishing procedures such as polishing or nickel plating not only improve aesthetics but also enhance part performance by reducing friction, preventing corrosion, or increasing durability.

For example, polished aerospace components subject to aerodynamic forces are expected to behave better under such forces, and smooth surfaces of a medical implant have lower risks for patients. Thus, with every finishing added, machining time increases and total pricing is affected, making it highly critical in giving jobs a quote.

Design Optimization

Optimized designs form perhaps the smartest way to cut costs without acquiring losses in quality. Engineers save costly hours of machining. A slight alteration may eliminate unnecessary complexity in geometries, tool access, or tolerances.

A common practice is to identify optimization opportunities early in the design phase. It eliminates costly reworks later on. In other words, companies that closely couple CAD with CAM during their design operations see savings in both time and money. Extended tool life, minimized material wastage, and maximized machine efficiency are all benefits of optimized design.

Geography

These geographical variations make some of the most important considerations in assessing machining costs. Machining charges at a shop in China or India may well be half of what those in Germany or the United States are going to charge, simply because of labor and energy costs.

But once again, these international options for outsourcing will require the consideration of things like logistics, shipping costs, time zones, and even possible language barriers. Hence, it is a matter of weighing a lower price against the possible interference by delays or quality issues. One can find some local machineries that offer a higher hourly rate than some others, but may actually cost less as a total when logistics are factored in..

Additional Considerations

Many hidden factors affect cost apart from machine rates. The shops must consider tooling changes, machine depreciation, inspection time, and certification standards. Each of these factors contributes to final pricing, even though the basic machining rate is in the competitive range.

Among the commonly incurred cost drivers are:

- Frequency of tooling changes

- Machine depreciation

- Inspection and metrology requirements

- Adherence to industry certifications

Materials Choice and Price-Profit Analysis

Choice of material is the major factor in any overall cost profile and profitability. Some metals are easier to cut and less demanding on tools, but others require more time, a high force for cutting, and frequent changes of tools.

| Материал | Typical Price Impact | Profit Considerations |

| Алюминий | Low to Medium | Easy to machine and cost-effective |

| Титан | Высокий | Expensive tools wear out, and these wear costs |

| Нержавеющая сталь | Medium | Balance of durability and machinability |

| Exotic Alloys | Очень высокий | Niche +J6:L10dustries, higher margins |

Material selection determines cost and profit directly.

Typical Hourly Rates of 5 Axis CNC Machining

The hourly rates include not only the machine but also labor, power, maintenance, and the shop overhead. A highly automated shop may charge even more for the same piece but could be faster in output, reducing total project costs. A lower hourly rate may be more attractive, but it would result in more machining time and lower accuracy.

On average, hourly rates of 5-axis machining range between $75-$200 per hour, affected by complexity, region, and service provider. Some specialized aerospace-grade machines could charge more than $300 for every hour of operation, particularly where ranges are very high..

Typical Hourly Ranges (By Machine Class and Region)

It could be valuable to relate the machine class and location when evaluating estimates. Pricing tends to vary per region:

Entry-level machines in Asia: $50 - $80 per hour

Middle-level machines in Eastern Europe: $80 - $120 per hour

State-of-the-art aerospace-grade machines in the USA/Germany: $150 - $300 per hour

Business comparisons can further include geographical ranges under such pricing conditions, which illustrate the effect of geography on machining economics. Such ranges should be compared, in such cases, with each enterprise's quality requirements and turnaround times.

Comparing the Different Pricing Models

One Flat Shop Rate vs Tiered Machine Rates

These shops may have different ways of levying charges. Flat pricing for customers is simplified. However, it does not consider the type of machine in use. Charging for machine time, on the other hand, charges more for advanced 5-axis machines and less for simpler setups. Therefore, it balances the load more equitably, although quoting sounds complex for some new clients.

Direct Shop Quotes vs Platform Quotes

Before anything, businesses must determine whether they will deal directly with a shop or engage via a platform before requesting a machining service. Innovation requires consideration of other things, such as finishing, tolerances, and delivery time, to provide a direct quote.

CNC platform quotes are the quickest and cheapest, less flexible and communicative.

Specialized Applications of 5-Axis CNC Machining in Various Industries

The stronghold of 5-axis CNC machining lies within the fact that it has its resilience across industries. Some of the best applications are as follows:

Аэрокосмическая промышленность: Turbine blades, engine housings, wing structures

Медицина: Bone implants, surgical tools, dental prosthetics

Автомобиль: Engine blocks, EV battery housings, lightweight frames

Энергия: Wind turbine hubs, oil and gas components

Defense: Precision weapon parts, satellite components

These industries, ranging from aerospace to defense, will favor the application of 5-axis due to its capability to achieve complex shapes.

Tips to Keep Your Hourly Cost Down in 5 Axis CNC Machining

A cheap shop should not be anything but to reduce costs. It is about making intelligent choices at any production stage. These intelligent strategy decisions will stretch out the saving opportunity and will keep costs low while producing quality.

- Optimize part design before machining.

- Use local suppliers for faster turnaround.

- Batch produce to get better prices per unit.

- Regularly maintain tools to avoid downtime.

- Compare multiple quotes before outsourcing.

DEK for the Best 5-Axis CNC Machining Outsourcing Services

At DEK, we offer top-quality 5-axis CNC machining with global standards at very low prices. We have an experienced team that ensures precision, speed, and efficiency for both prototypes and large-scale production. Свяжитесь с нами today for customized solutions that save your costs and your valuable time.

Заключение

Determining the cost of CNC machining on five axes includes several parameters, like the actual machining type, material or machine part, man-hours, and the geographical location. With clever approaches, companies can effectively reduce costs, delivering precision work.