If you’re making parts for airplanes or spacecraft, you know they have to be exact. There’s no room for mistakes. That’s why it’s important to learn how to achieve precision in aerospace parts.

In this blog, I’ll show you what makes aerospace machining different, what challenges you might face, how to make every part as accurate as possible, and much more.

Важность точности в аэрокосмической промышленности

In aerospace, you have to make every part very exact. Even a small mistake can be dangerous or cost a lot of money.

You need to follow strict rules for size, shape, and strength. That’s why you use advanced CNC machines to make parts the right way and fast.

Advantages of Using CNC Machining For Aerospace Parts

Here are the main benefits when you use CNC machining for aerospace components:

- CNC machining helps you create strong yet lightweight aerospace parts using materials like aluminum and titanium. These materials improve fuel efficiency and performance while keeping parts durable.

- CNC machines are highly precise, reducing errors and ensuring parts meet exact specifications. This automation also cuts down on human mistakes, so your parts are safer and more reliable.

- CNC machining provides the accuracy needed for aerospace parts. It achieves tight tolerances, ensuring your parts perform well under extreme conditions like those in engines and aircraft structures.

- Whether you need one part or a thousand, CNC machining guarantees each one is made with the same high precision. This consistency is crucial for maintaining quality and meeting strict aerospace standards.

- CNC machines work quickly and continuously, speeding up production and reducing waste. This efficiency saves time and money, especially when using expensive materials.

- CNC machining lowers labor costs by automating tasks and reducing errors.

- CNC machining can create intricate shapes that are difficult with traditional methods. This capability helps meet strict design requirements for advanced aerospace systems.

- CNC machining is faster than traditional methods, allowing quicker production and prototyping. This speeds up development and helps get new designs to market faster.

Challenges in High-Precision Aerospace Components

Manufacturing aerospace parts is not easy, so you may encounter these challenges:

Performance Under Extreme Conditions

You often need to use parts in places with high heat, pressure, and speed. That’s why you work with strong materials like titanium and nickel-based superalloys. But these materials are hard to machine, as they wear down your tools fast.

To get around this, you can use techniques like high-speed machining and adaptive control. These help you stay accurate and make your tools last longer.

Material Complexity and Micron-Level Tolerance Control

In aerospace machining, you need to meet very tight micron-level tolerances. Even tiny mistakes can affect how the part works or put safety at risk.

To do this right, you use advanced machines like multi-axis CNC machines and precise measurement tools. It also helps if you keep your workspace stable by controlling temperature and humidity, so your parts stay the right size and shape.

Key Factors for Achieving Precision

Now, let’s talk about how to achieve precision in aerospace parts by considering the following factors:

Material Selection and Pre-Treatment

To achieve precision, you need to choose materials that offer consistent and reliable properties. Make sure the material is suitable for tight tolerances and won’t shift or warp during processing.

Before you start machining or fabrication, apply pre-treatment methods like stress relief or annealing to stabilize the material. This step helps reduce internal stresses and improves accuracy during production.

Different parts of an aircraft need different types of materials. Here are some common ones you might use:

| Тип материала | Examples | Uses | Характеристики |

| Алюминиевые сплавы | 6061, 7075 | Fuselage panels, frames, interior parts | Light, resists rust |

| Титановые сплавы | Ti-6AI-4V | Engine parts (turbine blades, discs), strong structures | Very strong, handles heat well |

| Stainless Steels | 15-5, 17-4 PH | Landing gear, strong fittings | Strong, rust-resistant, durable |

| High-Strength Steels | 4340, 300M | Gears, shafts, high-stress parts | Super strong and tough |

| Nickel-Based Alloys | Inconel 718, Hastelloy | Gas turbines, exhaust systems | Great in heat, resist rust |

| Композиты | CFRP, GFRP | Panels, fairings, aircraft interior | Very light, very strong |

| Медные сплавы | Brass, Bronze | Electrical parts, heat exchangers | Conducts electricity, resists corrosion |

| Plastics & Polymers | PEEK, Ultem | Interior parts, insulators | Light, handles chemicals and heat well |

Design and Engineering

You should begin with a solid digital foundation using a computer-aided design (CAD) to create highly accurate models. This allows you to catch potential issues early and refine your design before production.

It’s also important to apply design for manufacturability (DFM) principles. By doing so, you make sure your part is not only functional but also practical to manufacture with precision.

Advanced Manufacturing Technologies

Using advanced manufacturing technologies is key to achieving high precision. You’ll want to rely on advanced equipment like CNC machines, EDM systems, or laser cutters that offer tight control and repeatability.

Integrating automation and real-time monitoring into your process can further improve consistency and help reduce human error.

Below are the important advanced techniques commonly used in aerospace CNC machining:

Прецизионная обработка

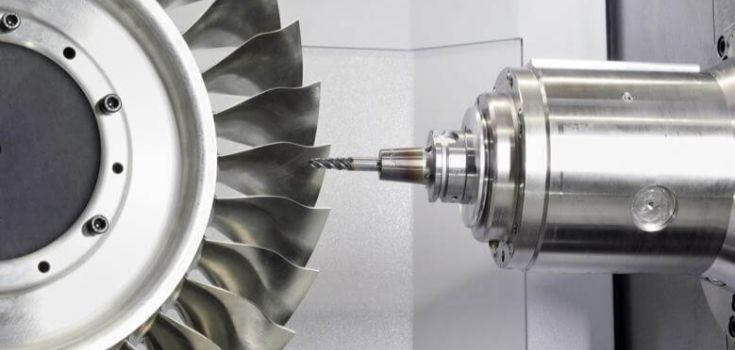

5-Axis CNC machining centers: This technique uses machines that move in five different directions at the same time. You can create very detailed shapes without stopping to reset the machine. This saves you time and gives you more accurate parts.

Ultra-Precision Grinding: If you need super smooth surfaces and tight fits, this method helps you do that. It’s perfect for parts that go through a lot of stress.

Electrical Discharge Machining (EDM): This helps you cut very hard metals or tiny shapes. It works by using electrical sparks to melt the material. Great when you need tiny holes or special inner shapes.

Лазерная резка: A laser cuts fast without touching the part. This means there’s less heat damage. Use it when you’re working with thin sheets or delicate materials.

Аддитивное производство

This advanced technique is also known as 3D printing. You build the part layer by layer instead of cutting it out of a block. This lets you make lighter, stronger, and more complex shapes, and you waste less material.

Combine 3D Printing and CNC

First, you 3d print the part to get the shape you want. Then, you use Обработка на станках с ЧПУ to make it smoother and more exact. This way, you get creative designs and very precise results at the same time.

Quality Control and Inspection

You can’t achieve true precision without thorough quality control. Use advanced inspection tools such as coordinate measuring machines (CMM), laser scanners, or optical comparators to verify accuracy.

Make sure to inspect parts during the process as well as after they’re finished, so you can catch and correct issues early, ensuring everything meets your exact standards.

Case Studies

Here are some real-life examples of how CNC machining is used in the aerospace industry:

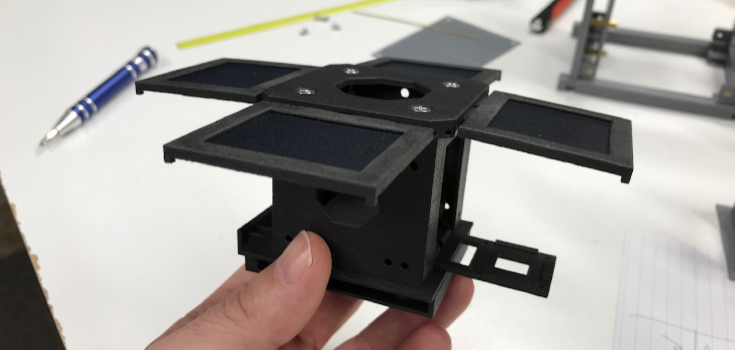

Rapid CNC Machining for Satellite Components

A satellite company teamed up with DEK to make important parts for their space projects. We used both 3-axis and 5-axis CNC machines to create parts from materials like aluminum, PEEK, and POM. This teamwork helped us quickly produce strong structures and detailed brackets for their satellites, cutting down on wait times and speeding up the whole design and build process.

Enhancing Landing Gear Manufacturing

An aerospace company had trouble machining landing gear parts made from tough materials like titanium and steel. To solve this, they asked help from DEK. We used advanced CNC technology, like 5-axis machines, real-time sensors, and automatic inspection systems, to produce parts fast, improve quality, and meet strict safety standards more easily.

Precision Aluminum Aircraft Fittings

DEK created custom aluminum fittings for aircraft that had complex shapes and very tight tolerances. We used a 5-axis CNC turning center to handle the detailed work. After machining, the parts were anodized and carefully inspected to make sure everything met high quality standards. The finished components were delivered on time and ready to use.

Manufacturing Military-Grade Aerospace Instruments

DEK used high-speed CNC machines to make illuminated control panels from strong, military-grade acrylic. We used techniques like dynamic surface adjustments, multi-step machining, and added electronic parts during the process. The result was highly precise and durable panels made for use in aerospace settings.

CNC Plastic Machining for Lightweight Aerospace Components

An aerospace team worked with DEK to switch some metal parts to PEEK plastic, hoping to make the aircraft lighter and use less fuel. By using CNC machines, we were able to shape PEEK into complex, high-precision parts. The final components were lighter, tough, and helped improve the aircraft’s overall performance.

Precision in Turbine Blade Manufacturing

An aerospace manufacturer needed to make turbine blades that could handle extreme heat and stress with high precision. They partnered with DEK, and we used multi-axis CNC machines to shape the blades from strong materials like Inconel and titanium.

After machining, the blades were heat-treated and coated for extra strength. This process ensured the blades were durable, precise, and met strict standards, all while being produced quickly and efficiently for use in jet engines.

DEK’s Precision Aerospace CNC Machining Services

DEK is known for providing quality, reliability, affordable prices, and on-time delivery in CNC machining. Our team of machinists and engineers will work closely with you on your aerospace machining projects, from prototype to production.

We understand every project is different, so we offer custom solutions, including precision machining and surface finishing. Свяжитесь с нами today, and let’s start creating your high-quality aerospace part.

Заключение

Getting precision in aerospace parts is really important for safety and performance. By using advanced CNC machining, picking the right materials, and making sure everything is checked for quality, you can make parts that meet the high standards needed in aerospace.