Steel is often coated with zinc to protect it from rust and corrosion. Two common methods for this are galvanizing and galvannealing. Both add protection, but they have different properties and uses.

This blog will help you understand the difference between galvanneal vs galvanized steel.

What is Galvanized Steel?

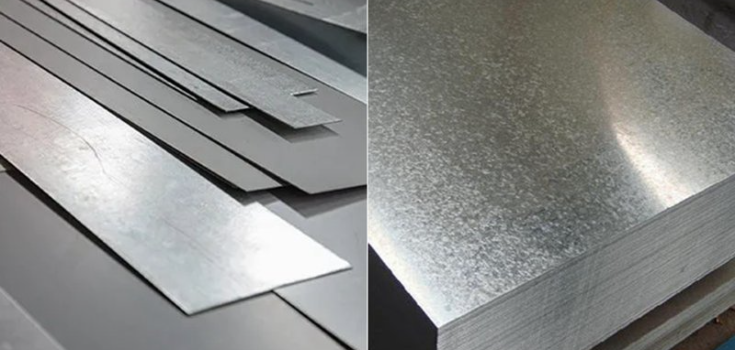

Galvanized steel is regular steel covered with zinc to help prevent rust. The steel is dipped in very hot liquid zinc (about 850°F), and any extra zinc is removed to make it the right thickness. The zinc sticks to the steel, and that is the reason why it is strong and long-lasting.

What Does Galvanized Steel Look Like?

Galvanized steel has a shiny, silver-gray color with a unique pattern of small, shiny specks called spangles. It has a smooth texture and a metallic appearance.

Applications of Galvanized Steel

Galvanized steel has so many uses. Here are some everyday things made from galvanized steel:

Pipes: Some pipes are made from galvanized steel because it is strong and doesn’t rust easily.

Fasteners: Nuts, bolts, nails, and screws often have a galvanized coating to prevent rust, especially for outdoor use.

Vehicles: Many car bodies are made from galvanized steel to help them last longer and resist rust. Some bicycles are also made from it.

Roofing Sheets: Used for roofs because they don’t rust easily.

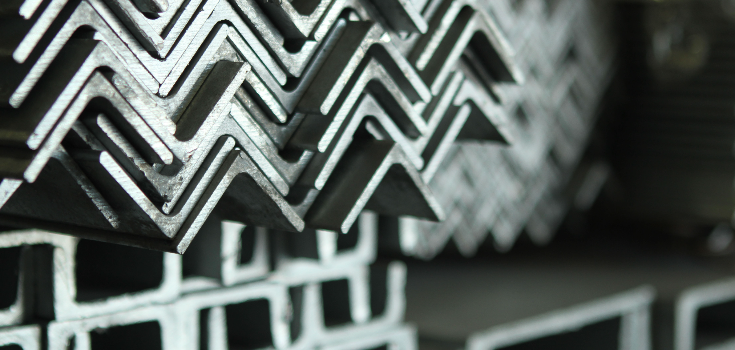

Structural Steel: Beams and other building supports are often galvanized to stay strong and resist rust over time.

Galvanization Processes

There are different ways to galvanize steel, but the most common method is hot-dip galvanizing. Below, you’ll learn about this process and a few other ways to galvanize metal.

Горячее цинкование

Hot-dip galvanizing is the most popular method. It involves dipping the metal into molten zinc to create a protective layer. Here are the steps:

1. Cleaning

First, you need to remove any grease, oil, or dirt from the metal. This ensures a smooth and even coating. You can clean it using special degreasing solutions or other methods, depending on the type of dirt.

2. Pickling

Next, you soak the metal in a mild acid solution to remove rust and prepare it for coating. This step helps the zinc stick better.

3. Fluxing

To improve bonding, you apply a zinc-ammonium chloride solution. This helps the zinc attach firmly to the metal.

4. Galvanizing

Now, you dip the metal into molten zinc (about 850°F). The zinc reacts with the metal, forming a protective layer that prevents rust.

5. Post-processing

After coating, you check the thickness and quality of the zinc layer. Sometimes, air knives (a tool that blows air) help control the thickness. If needed, you can also paint the metal for extra protection.

Other Galvanizing Methods

Besides hot-dip galvanizing, here are some other ways to coat metal with zinc:

Thermal Spray (Metallizing)

In this method, you first clean the metal using grit blasting. Then, you spray it with semi-molten zinc using an electric arc or plasma heat source. This method allows you to control the coating thickness and is good for complex shapes. However, it’s more expensive.

Electrogalvanization

This method uses electricity to apply a zinc coating. You place the metal in a zinc salt solution with a zinc plate. When you pass electricity through the solution, zinc sticks to the metal. This process is affordable, precise, and works well for small parts like screws and bolts.

Sherardizing

In this method, you place the metal part in a rotating drum with zinc dust and sand. You heat the drum to around 380°C (716°F), which melts the zinc and bonds it to the metal. This method is useful for small parts and provides strong protection.

Преимущества оцинкованной стали

Galvanized steel has several advantages over regular steel and other types of treated steel:

- The zinc coating helps prevent rust. It is great for outdoor use and areas with lots of water.

- It is more affordable to produce compared to other rust-resistant steels.

- Once installed, it doesn’t need extra maintenance or treatments.

- It combines the strength of steel with the rust protection of zinc, so it lasts much longer than regular steel.

Disadvantages of Galvanized Steel

Even though galvanized steel has many benefits, it also has some drawbacks:

- The zinc can leak into the environment, which may be harmful.

- The zinc coating can crack or chip, exposing the steel underneath. This weakens its rust resistance and can make it look worn out.

- It is less flexible because the galvanizing process makes the metal more rigid.

- The zinc coating adds extra weight to the steel.

What is Galvanneal Steel?

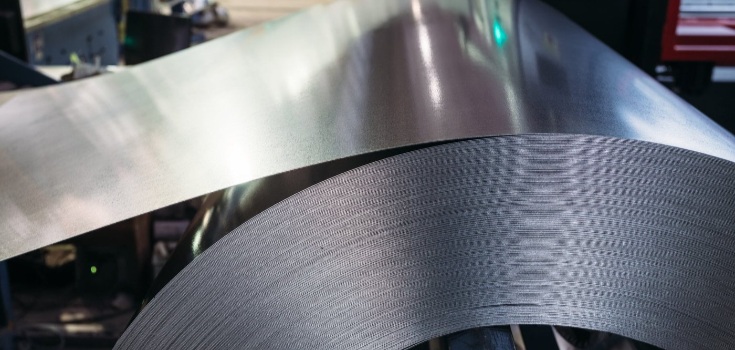

Galvannealed steel starts with a zinc coating, just like galvanized steel, but then goes through an extra heating step.

Сайт сталь is heated to 1,050°F while the zinc is still liquid, allowing some iron to mix in. This forms a tough, rust-resistant zinc-iron layer on the surface, which is about 90% zinc and 10% iron. The coating is harder and more brittle than the regular zinc coating on galvanized steel.

What Does Galvannealed Steel Look Like?

Galvannealed steel has a dull gray finish that many people find attractive. Its surface is slightly rougher than untreated or freshly galvanized steel, but not too rough. The texture depends on how it’s made, though it’s usually not very noticeable.

If you look closely, you might see a faint grain pattern. The coating on galvannealed steel helps paint stick well, so many products made from it are painted or coated for extra protection.

Applications of Galvannealed Steel

If you need something that bends, paints, or welds more easily, galvannealed steel is better than galvanized steel. You can find galvannealed steel in many common products, such as:

Building Materials: It’s used in architecture because it has a nice, smooth surface.

Car Parts: Many car doors and panels are made from it since it’s strong, resists rust, and holds paint well

Бытовая техника: It’s used in the frames and structural parts of appliances like refrigerators and ovens.

Электрооборудование: You’ll see it in things like electrical conduits, enclosures, and junction boxes.

Galvanneal Process

Galvannealing is like galvanizing, but it adds an extra step called annealing. First, you clean, pickle, flux, and galvanize the metal using hot-dip galvanization. Then, you heat the metal to about 1050°F in an annealing oven.

During annealing, the iron in the steel melts and moves to the surface, where it mixes with the zinc coating to form a strong alloy. This makes galvannealed steel tougher, easier to weld, and less likely to get damaged compared to regular galvanized steel. You can also use temper rolling to make the surface smoother.

Galvannealed steel is labeled with an “A” rating. Two common types are A40 and A60.

- A40 has a thin coating (0.40 oz per square foot), which helps with shaping the metal while still offering protection.

- A60 has a thicker coating (0.60 oz per square foot), providing better surface protection.

Advantages of Galvannealed Steel

Here are some of the good things about galvannealed steel:

- You can easily bend it into different shapes because it’s very flexible.

- It resists rust well because of its zinc-iron coating.

- The iron in the coating makes it harder and stronger, so it doesn’t chip or scratch easily.

- It’s easier to weld than galvanized steel because of the iron in the coating.

- Its rough surface helps paint stick better, so you get a nice, even finish.

Disadvantages of Galvannealed Steel

Below are the downsides of galvannealed steel:

- It doesn’t resist rust as well as galvanized steel, so it’s best to paint it for extra protection.

- It costs more to make because it goes through an extra heating step after being galvanized.

- The hard coating can make it more brittle, so it’s not great for applications that need flexibility.

- The zinc in the coating can release harmful chemicals into the environment.

Chemical Properties of Galvanneal Steel vs Galvanized Steel

Galvanized and galvannealed steels have different chemical properties. Here’s a simple comparison:

| Недвижимость | Оцинкованная сталь | Galvannealed Steel |

| Свариваемость | Ярмарка | Хорошо |

| Устойчивость к коррозии | Превосходно | Хорошо |

| Coating Composition | Pure zinc | 90% zinc, 10% iron alloy |

Physical Properties of Galvannealed Steel vs Galvanized Steel

Here’s a simple comparison of their physical properties:

| Недвижимость | Оцинкованная сталь | Galvannealed Steel |

| Внешний вид | Shiny, silver-gray | Dull, gray matte |

| Пластичность | Good (can bend) | Excellent (bends even better) |

| Отделка поверхности | Smooth | Rough, matte |

| Формуемость | Fair (okay for shaping) | Good (easier to shape) |

| Термостойкость | Умеренный | Умеренный |

Similarities Between Galvanized vs Galvannealed Steel

Even though they are different, galvanneal and galvanized steel have some things in common. The most important one is that both follow the ASTM A 653/A 653M standard. But there are other similarities you should know.

Свойства

Both types of steel have a zinc coating that helps prevent rust and corrosion. They are also very strong and long-lasting, making them good for building and structural products. However, galvanneal steel resists rust and corrosion better than galvanized steel.

Процесс

Both go through a hot-dip galvanizing process to get a zinc coating of the same weight. However, the makeup of the coating is different for galvanneal steel.

What is the Difference Between Galvanized and Galvannealed Steel

Before you choose between galvanneal and galvanized steel, you should know how they differ. Here are the main points:

Покрытие

Galvanized steel is covered mainly with zinc and might include a little iron. With galvanneal steel, the annealing process creates three layers of coating (zeta, delta, and gamma). The gamma layer, which is closest to the steel, has the most iron. This makes the coating on galvanneal steel stronger, so it’s harder and more durable.

Свариваемость

The extra iron in galvanneal steel makes it easier for you to weld compared to galvanized steel. This means galvannealed steel is better for spot welding and offers better electrical resistance, hardness, and a higher melting point.

Paintability

Galvanized steel has a porous surface that makes it easier for you to paint. The porous surface means you don’t need to sand it first, and the paint sticks better.

Формуемость

Because galvanized steel has a softer coating, you can machine it more easily with processes like CNC machining. On the other hand, galvannealed steel is very strong and ductile, which gives you better formability.

Стоимость

Galvanneal steel usually costs more than galvanized steel because of the extra annealing step. You pay a bit more, but you also get better rust and corrosion resistance, weldability, and formability.

Choosing Between Galvanneal vs Galvanized Steel

When picking the right steel, consider these key factors:

Project Needs

For strong rust protection, especially outdoors, go with galvanized steel. It’s great for gutters, roofs, and fences, but hard to paint.

If you need a painted finish, galvannealed steel is better. Its surface holds paint well. It is ideal for appliances, HVAC ducts, and metal furniture.

Условия окружающей среды

Galvanized steel is best for harsh outdoor conditions like heavy rain, snow, or salt exposure.

Galvannealed steel resists rust, too, but works better indoors or in mild outdoor settings.

Стоимость

Galvanized steel is usually cheaper, but painting it takes extra effort and cost.

Galvannealed steel costs more upfront but saves time and money if painting is required.

Доступность

Both are widely available, but galvanized steel comes in more sizes. If you need a specific size of galvannealed steel, you may have to special order it.

Резюме

Now that you understand the differences between galvanneal and galvanized steel, you can choose the best one for your project. Galvanized steel is great for rust protection in outdoor environments, while galvannealed steel is better for painted applications and welding.

На сайте DEK, we specialize in high-quality steel processing, including galvanneal and galvanized materials. Our experts are ready to help, so contact us today to discuss your project and get the best steel solutions for your needs!

Вопросы и ответы

Is galvanized steel good?

Yes, galvanized steel is good for many uses. It resists rust, lasts a long time, and is affordable. However, its coating can chip or scratch, and welding it releases toxic fumes. It’s best for outdoor structures, roofing, and other applications needing corrosion resistance.

Is galvanized steel stronger than galvannealed steel?

Not necessarily. Galvanized steel has a zinc coating that resists rust but can chip or scratch. Galvannealed steel has a tougher zinc-iron coating that resists damage better. However, the overall strength depends on the steel itself and coating thickness.

Can you weld both galvanized and galvannealed steel?

Yes, but galvannealed steel is easier to weld. Galvanized steel releases toxic fumes when welded, requiring proper ventilation and safety gear. Galvannealed steel produces fewer fumes and welds better.

Is galvannealed steel better at preventing rust than galvanized steel?

No. Galvanized steel has a thicker zinc coating, so it is better at preventing rust. If rust resistance is your priority, galvanized steel is a better choice.

Can you use galvanized and galvannealed steel for form milling?

Yes, but both have challenges. Too much heat can burn off galvanized steel’s zinc coating, reducing rust protection and releasing fumes. Galvannealed steel is easier to machine but still requires heat control and safety precautions.