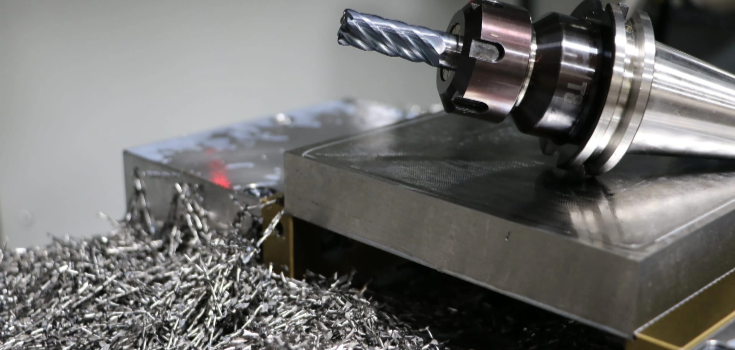

CNC machining helps you make precise parts, but sometimes things go wrong. These problems can slow down your work and increase costs.

But don’t worry– most machining defects have simple fixes. In this blog, you will learn about common CNC machining defects and how to fix them.

Что такое обработка с ЧПУ?

CNC machining is a way to control machines like lathes, mills, and grinders using a computer. The computer follows a digital design to shape a final part by cutting away material.

These machines are important because they can make complex parts with great accuracy and consistency. Many industries rely on them.

Common CNC Machining Defects and How to Fix Them

In this section, let’s discuss the common CNC machining defects, their causes, and how to fix or prevent them.

Dimensional Inaccuracies

If the part doesn’t match the required measurements, it might not fit or function properly.

Possible Causes:

- If your CNC machine isn’t properly calibrated, dimensions will be off.

- Some materials behave differently under machining, affecting accuracy.

- Changes in the environment can slightly alter material size.

How to Fix It:

- Check and recalibrate your machine often.

- Ensure your materials are stable and reliable.

- Try to keep the temperature and humidity steady.

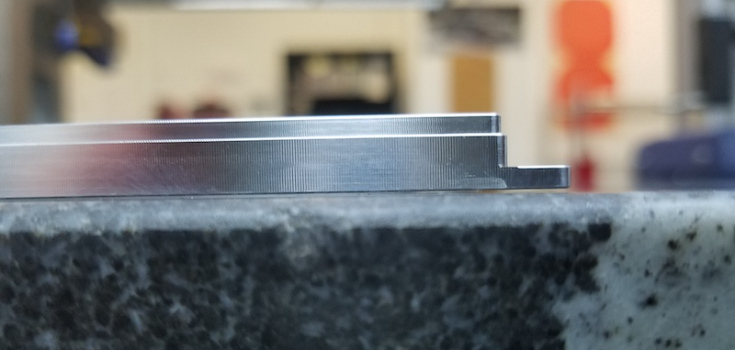

Poor Surface Finish

If your finished part has rough textures or visible lines, it can affect how it looks and works.

Possible Causes:

- If your tool vibrates too much, it can leave uneven marks. This happens when tools are dull, cutting strategies are incorrect, or cooling is insufficient.

- A feed rate that’s too fast can make the tool shake, leaving marks.

How to Fix It:

- Keep your tools sharp and use the right cutting strategy to avoid chatter.

- Lower the feed rate or adjust the spindle speed for a smoother surface.

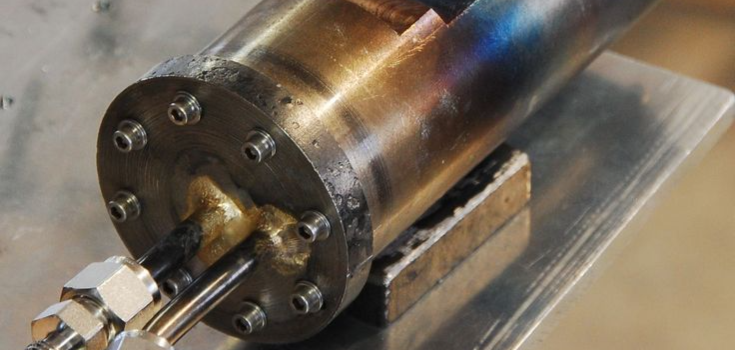

Tool Wear and Breakage

Cutting tools can snap unexpectedly, which slows down production and increases costs.

Possible Causes:

- Too much pressure can break the tool.

- Some tools wear out faster when used on the wrong material.

- Heat buildup can make tools brittle.

- Overused tools eventually break.

How to Fix It:

- Adjust settings to reduce stress on the tool.

- Pick tools that match the material you’re machining.

- Prevent overheating with the right coolant.

- Inspect tools often and swap them out before they fail.

Burrs and Sharp Edges

Burrs are tiny, unwanted edges or rough spots on your part, usually around corners or edges.

Possible Causes:

- Softer materials and dull tools can create burrs.

- Incorrect cutting settings can make burrs worse.

- A damaged tool can cause rough edges.

How to Fix It:

- You can remove burrs manually with a file or sandpaper, or use advanced techniques like thermal or vibratory deburring.

- Replace dull tools or sharpen them regularly.

- Change tool paths, use chip breakers, or modify cutting speeds to reduce burr formation.

Material Deformation

This happens when a part changes shape unintentionally, often bending or twisting.

Possible Causes:

- Some materials have built-up stress that releases during cutting.

- If a part isn’t properly supported, it can warp.

How to Fix It:

- Choose stable techniques and fixtures to hold the part securely.

- Heat treatment or post-machining stress relief can prevent warping.

Burn Marks

If you see dark or discolored spots on your workpiece, it may be overheating during machining.

Possible Causes:

- Too much friction from incorrect settings can cause overheating.

- If there’s not enough coolant, especially for heat-sensitive materials like titanium, overheating can occur.

How to Fix It:

- Lowering the cutting speed and increasing the feed rate can reduce heat buildup.

- Use more coolant or better cooling techniques for heat-sensitive materials.

Chatter Marks

These are wavy lines on the surface of your part caused by tool vibrations.

Possible Causes:

- If the tool isn’t stable, it will vibrate.

- A shaky machine foundation or an unsupported workpiece can make vibrations worse.

How to Fix It:

- Changing the feed rate and spindle speed can help reduce vibrations.

- Make sure it’s clamped tightly and properly supported.

- Some tools are designed to reduce vibrations and improve surface quality.

Tool Marks

These are lines or ridges left on the surface of a part due to the tool interacting with the material.

Possible Causes:

- Using the wrong cutting tool or aggressive settings can cause these marks.

- An unstable machine setup can leave unwanted lines.

- The way the tool starts and stops cutting can also affect the surface.

How to Fix It:

- Reduce pressure and refine tool movement.

- Use tools with better coatings or geometries.

- Finish the part with extra smoothing steps if needed.

Built-Up Edge

BUE happens when material sticks to the cutting tool. This makes machining less precise.

Possible Causes:

- Too much friction causes chips to stick to the tool.

- Poor settings can make the tool work inefficiently.

- Without proper lubrication, materials can overheat and stick.

How to Fix It:

- Tools with special coatings reduce material buildup.

- Use the right coolant or lubricant to minimize friction.

Cracking or Fracturing

Parts can crack or break during machining, especially if they are brittle or under too much stress.

Possible Causes:

- Applying too much force can break a part.

- A poor cutting path can create stress points.

- Some materials are tough to cut, and weaker tools may not handle them well.

How to Fix It:

- Sharp tools make cleaner cuts with less force.

- Tools with coatings like carbide or diamond last longer.

- Use tools with multiple cutting edges to spread out the force.

Incomplete Cuts or Poor Detail Resolution

If a CNC machine doesn’t cut all the way through or leaves out details, the final part won’t match the design.

Possible Causes:

- A worn-out or incorrect tool can miss fine details.

- Speed and feed rate settings might be off.

- Vibrations or loose parts can make cuts less precise.

- Mistakes in the CNC code can cause missing details.

How to Fix It:

- Keep cutting tools in top condition.

- Optimize speed and feed rate for better accuracy.

- Reduce vibrations and check for loose parts.

- Double-check the program to ensure it follows the design correctly.

Dents or Impressions

Dents or impressions appear as unwanted surface depressions, often caused by tooling or clamping methods.

Possible Causes:

- Excess clamping force, especially with softer materials.

- Tool impact or improper handling.

How to Fix It:

- Use intermediate steel plates to evenly distribute clamping pressure.

- Invest in specialized chucks and fixtures designed to minimize surface damage.

- Adjust clamping methods to apply only the necessary force.

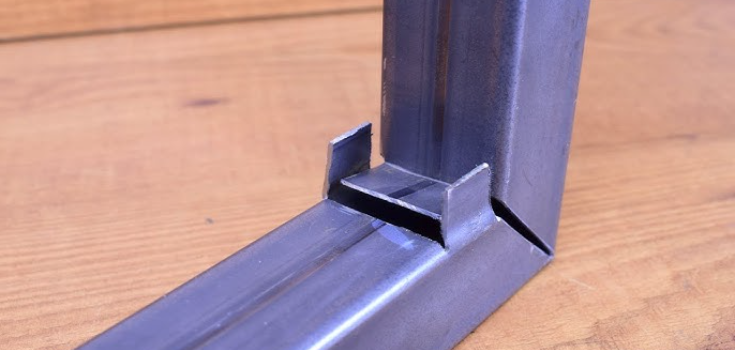

Mismatched Seams or Joints

Mismatched seams or joints occur when two parts or sections do not align correctly, resulting in uneven surfaces.

Possible Causes:

- Inaccurate programming or tool path errors.

- Machine wear or misalignment.

- Inconsistent material properties.

- Variations in clamping force or misalignment during assembly.

How to Fix It:

- Ensure accurate programming and tool paths.

- Perform regular maintenance and calibration of CNC machines.

- Use high-quality, consistent materials.

- Carefully align and secure parts during setup and assembly.

Internal Stress and Distortion

Internal stress and distortion occur when a machined part warps due to the release of internal stresses.

Possible Causes:

- Residual stresses from prior material processing.

- Uneven cutting forces.

- Inadequate support or clamping.

- Excessive heat during machining.

How to Fix It:

- Apply stress-relieving treatments before machining.

- Optimize cutting parameters to distribute forces evenly.

- Use rigid supports and clamping to prevent movement.

- Control heat with effective cooling techniques.

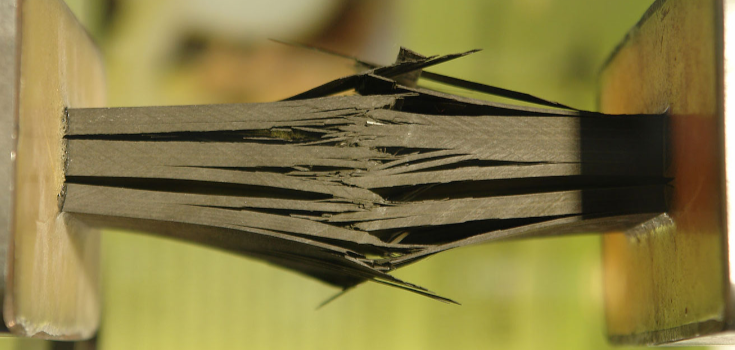

Delamination

Delamination occurs when layers in laminated materials separate or peel apart during machining.

Possible Causes:

- Excessive cutting forces or feed rates.

- Poor-quality or weakly bonded laminates.

- Incorrect tool selection or worn-out tools.

- Inadequate clamping, leading to vibration or movement.

How to Fix It:

- Reduce cutting forces and feed rates.

- Use high-quality, well-bonded laminated materials.

- Choose sharp, appropriate tools for laminated materials.

- Provide sufficient support and clamping to prevent movement.

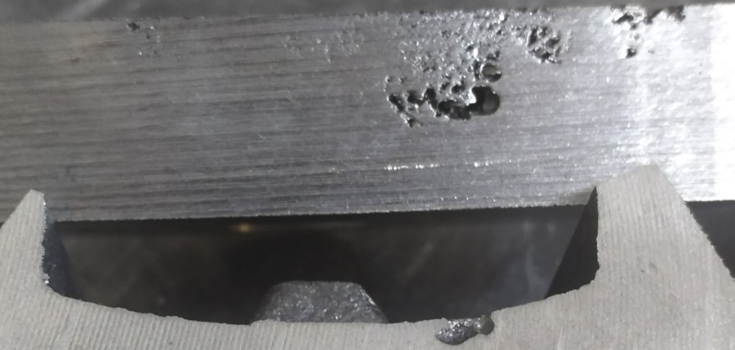

Residual Material

Residual material, or burrs, are thin, unwanted material left on the edges of a machined part.

Possible Cause:

- The final layer of material deforms instead of being cleanly removed.

How to Fix It:

- Use deburring techniques such as manual grinding, filing, or sanding.

- Apply advanced deburring methods like thermal or vibratory deburring.

Corner Radius Issues

Corner radius issues occur when corners are not machined to the correct specifications, particularly in concave features.

Possible Cause:

- High machining forces cause tool deflection.

How to Fix It:

- Use smaller finishing tools to refine concave corners.

- Adjust tool size and machining approach to prevent inaccuracies.

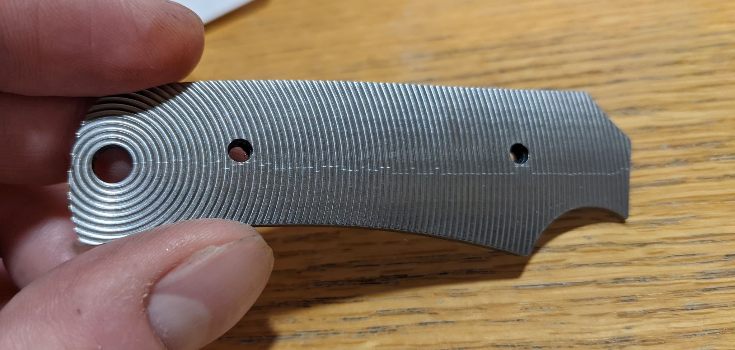

Swirl Marks

Swirl marks appear as circular surface defects, affecting both aesthetics and function.

Possible Cause:

- Incorrect feed rates or tool speeds.

How to Fix It:

- Optimize cutting speeds and feed rates for a smoother finish.

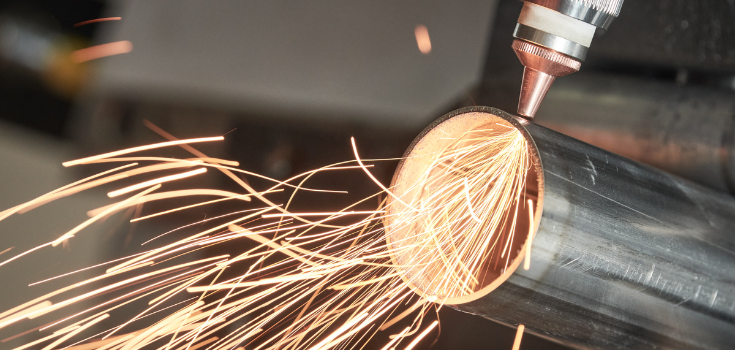

Thermal Damage

Thermal damage results from excessive heat during the machining process, causing material degradation or discoloration.

Possible Causes:

- High-speed operations without proper cooling.

- Excessive friction from worn tools.

How to Fix It:

- Ensure adequate cooling and lubrication.

- Adjust cutting speeds and feeds appropriately.

- Use sharp tools to minimize friction.

Chip Recutting

Chip recutting happens when the tool re-engages with chips that were not properly cleared, affecting surface quality.

Possible Causes:

- Inadequate chip evacuation.

- Inefficient tool paths.

How to Fix It:

- Improve chip evacuation using air blasts, coolant flow, or chip conveyors.

- Use chip breakers to reduce chip size.

- Optimize tool paths, such as climb milling, to prevent chip entrapment.

How Do CNC Machining Settings Cause Defects?

When you use a станок с ЧПУ, the way you set up your machining parameters affects the quality of the final part. If the items listed below are not set correctly, they can cause defects in your machined parts.

Скорость резки

Cutting speed is how fast the tool moves against the material. If the speed is too high or too low, it can create problems:

Too fast: Too much heat, which can damage the tool and the workpiece.

Too slow: The cutting might not be smooth, leading to rough surfaces.

Скорость подачи

This is how fast the material moves towards the cutting tool.

Too high: The tool can break, and the surface might be rough due to too much heat and friction.

Too low: Machining takes too long and might not be efficient.

Depth of Cut

This refers to how much material is removed in one pass.

Too deep: Can overload the tool, causing it to break or leave a rough surface.

Too shallow: Makes the process slow and inefficient.

How Do Material Properties Affect Machining Defects?

Different materials react in their own way when machined, which can lead to specific challenges and defects.

Металлы

Алюминий

- Since aluminum is soft, it easily forms burrs—tiny rough edges left after cutting.

- It can stick to cutting tools, ruining the surface finish and causing defects.

- Heat makes aluminum expand, which can lead to inaccurate sizes.

Нержавеющая сталь

- Heat and pressure can make it harder, so machining is more difficult.

- Its hardness can wear out tools faster, requiring frequent replacements.

- It’s tough, so it can vibrate while cutting, lowering workpiece quality.

Титан

- Cutting titanium generates a lot of heat, which can damage tools and warp the material.

- Some fluids used in machining can cause unwanted chemical reactions with titanium.

Латунь

- Brass cuts easily and has fewer defects, but sharp tools are needed for precise results.

Пластмассы

Акрил

- Can crack if not properly supported or if the tools aren’t sharp.

- Heat from machining can cause it to melt or deform.

Нейлон

- Heat can make nylon bend out of shape.

- Nylon takes in moisture, changing its size over time.

Поликарбонат

- Chips can wrap around tools– this can mess up the surface finish.

- It can warp or discolor if it gets too hot.

Композиты

Carbon Fiber Reinforced Plastics (CFRP)

- The layers may split apart while cutting.

- The carbon fibers are tough and can quickly dull tools.

Стекловолокно

- Cutting fiberglass can cause rough, frayed edges.

- It’s very abrasive and dulls tools quickly.

Дерево

Hardwoods (Oak, Maple, Etc.)

- If the tool is dull or too fast, hardwoods can burn.

- Cutting along the grain can cause chipping or splintering.

Softwoods (Pine, Cedar, Etc.)

- Compresses instead of cutting– this can make details less sharp.

- Softwoods may get a fuzzy or torn surface, especially along the grain.

How Can We Reduce CNC Machining Defects at DEK?

На сайте DEK, we provide high-quality Обработка на станках с ЧПУ for metal and plastic parts. We reduce defects using advanced inspection tools.

Our 3-, 4-, and 5-axis machines are well maintained for top performance. Skilled engineers handle complex designs with tight tolerances, ensuring precision. We carefully select and manage quality materials.

We communicate clearly, offer fast prototyping, and give instant design feedback. Advanced software helps us keep high standards. We work with trusted suppliers and value customer feedback to improve constantly.

Заключение

When you do CNC machining, it’s important to be aware of things that can lead to CNC machining defects or even cause CNC machining to fail.

The type of material you work with and the settings you choose for the machine are key. Different materials can cause different problems. If you don’t adjust the settings right, you might end up with rough edges, heat damage, or tools wearing out too fast.

By understanding these issues, you can avoid CNC machining defects, reduce the chance of CNC machining failures, and make sure your parts are precise and in good condition.