When you need strong and light custom parts, you can opt for CNC machining aluminum. The properties of aluminum will tell you if it’s exactly what you need.

In this guide, I’ll help you understand how CNC machining aluminum works. You’ll learn why aluminum is a good material for your custom project.

Что такое обработка алюминия с ЧПУ?

CNC machining aluminum means using computer-controlled machines to cut, shape, and make parts from aluminum material. With this process, you can create very detailed and complex designs that would be hard to do by hand.

CNC machines control everything carefully, so the custom aluminum parts you make are accurate and consistent. There are also special machines that can be set up just for working with aluminum’s unique properties.

Обработка алюминия с ЧПУ

Here are the CNC machining processes you can use for your custom aluminum parts:

Фрезерование с ЧПУ

Фрезерование с ЧПУ is a way to make custom aluminum machined parts by using a rotating cutting tool. The tool spins while the aluminum piece stays still. The machine removes material little by little in a very controlled way.

It can move in different directions to create complex shapes. With CNC milling, you can get very accurate and detailed parts.

Токарная обработка с ЧПУ

In CNC turning, the aluminum piece spins at high speed while a cutting tool stays in one place. The tool moves slowly against the spinning part to cut away material and shape it. CNC turning is perfect when you need round parts like tubes, rods, or rings.

Сверление с ЧПУ

Сверление с ЧПУ is used when you need to make holes in your aluminum machined parts. A drill bit spins and moves straight down into the material to create the hole. This method is great when your parts need to fit screws, bolts, or other pieces together.

Шлифование с ЧПУ

CNC grinding is used when you need a very smooth and precise finish on your aluminum machined part. In this process, a spinning grinding wheel slowly removes tiny amounts of material from the surface.

It’s a great way to make parts very flat, very smooth, or to meet very tight size tolerances. You usually use CNC grinding as a final step after milling or turning.

Benefits of Aluminum that Make it Suitable for CNC Machining

Using aluminum for CNC machining has many advantages, and these are the following:

Устойчивость к коррозии

Aluminum naturally resists corrosion and scratching in normal air and marine environments. You can make it even more resistant by anodizing it.

Keep in mind that different grades of aluminum have different levels of corrosion resistance, but the ones most commonly used in CNC machining are very good at it.

Обрабатываемость

Aluminum is easy to cut, shape, and work with. Because it is soft and chips easily, you can machine it quickly without using a lot of power. It also costs less to machine than steel.

For you, this means faster production, lower costs, and more accurate parts. Aluminum doesn’t deform much during machining, so it’s easier to reach tight tolerances.

Low Temperature Performance

Most materials get brittle and weak at very cold temperatures, but not aluminum. It keeps its strength, softness, and flexibility even when it’s freezing. This makes it a good choice if your parts need to work in very cold environments.

Соотношение прочности и веса

Aluminum is about three times lighter than steel, but it’s still very strong. This strong yet lightweight quality is called the strength-to-weight ratio.

Because of this, you can use aluminum for parts that need to be strong without being heavy, like in cars, airplanes, and other high-performance products.

Возможность вторичной переработки

CNC machining creates a lot of leftover chips and waste. Luckily, aluminum is highly recyclable. It doesn’t take much energy, time, or money to recycle aluminum, which can help save costs and reduce waste. Plus, using recyclable materials like aluminum is better for the environment.

Электропроводность

Pure aluminum conducts electricity very well. Even though aluminum alloys conduct a little less, they are still good enough for making electrical parts. But if you need a part where conductivity is a problem, aluminum might not be the right material.

What Types of Aluminum are Used in CNC Machining?

There are different types of aluminum that are commonly used in CNC machining, and some of these are the following:

| Алюминиевый сплав | Состав | UTS (MPa) | Плотность (г/см³) | Specific Strength (kN·m/kg) |

| 7075-T651 | AlZn5.5MgCu | 490 | 2.81 | 170 |

| 2024-T351 | AlCu4Mg1 | 430 | 2.79 | 150 |

| 6082-T651 | AlSi1MgMn | 310 | 2.68 | 120 |

| 6061-T6 | AlMg1SiCu | 310 | 2.7 | 115 |

| 5052-H32 | AlMg2.5 | 260 | 2.68 | 97 |

Алюминий 6061

You can use 6061 aluminum for many things, like manufacturing, building, making consumer products, and even in airplanes. It’s very versatile and easy to weld.

This aluminum is medium-strong, can be heat-treated, and resists rust very well. You’ll find it easy to machine and work with, especially when it’s softened/annealed.

Алюминий 7075

If you need very strong aluminum, you should choose 7075 aluminum. It’s one of the strongest types you can get. It also holds up well under repeated stress, which is why it is perfect for parts that go through a lot of pressure.

Алюминий 7075 is very popular in the aerospace industry, where parts need to be both strong and complex.

Алюминий 5052

You should use 5052 aluminum when you need something that bends easily without cracking. It’s very good at resisting rust, especially from saltwater, so it’s great for marine uses.

You can’t heat treat it to make it stronger, but it’s still a strong and flexible aluminum that’s easy to work with.

Алюминий 2024

If you need aluminum that’s strong and handles stress well, 2024 is also a good choice. It’s often used in airplanes and vehicles because it is tough.

But you should know that it doesn’t resist corrosion as well as other types, so it usually needs a protective coating.

Алюминий 6082

When you want a strong and tough aluminum that’s still easy to machine and weld, you can use 6082 aluminum. It’s great for building structures like bridges and towers.

It resists corrosion well and is often used when you need strength and good durability together.

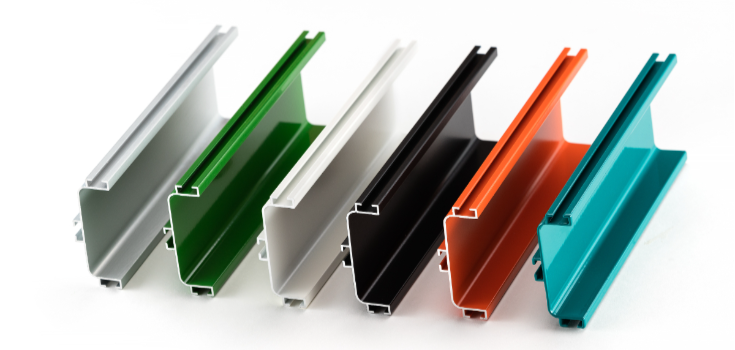

Surface Finishes for CNC Aluminum Parts

After you finish machining an aluminum part, you can do a few extra processes to make it look better, work better, and last longer. Here are the most common ones:

Покрытие

You can coat the aluminum part with another material, like zinc, nickel, or chrome. This makes the part stronger and protects it. Usually, you do this using an electrochemical process.

Another way to protect and color a part is by powder coating. You spray a dry colored powder onto the part using an electrostatic spray gun. Then you heat the part to about 200°C so the powder melts and sticks.

Обработка бисером

If you want a nice-looking finish, you can try bead blasting. In this process, you blast tiny glass beads at the part using a high-pressure air gun. This smooths the surface and gives a satin or matte look.

The main things you control are the size of the beads and the air pressure. Only use bead blasting if the exact size of your part is not super important, because it can change the dimensions a little.

Анодирование

If you want to make the surface harder and non-reactive, you can anodize the part. In anodizing, you dip the part into a diluted sulfuric acid solution and run electricity through it. This creates a tough aluminum oxide layer on the surface.

How thick and strong the layer gets depends on the solution, how long you anodize it, and the amount of electricity used. You can also anodize parts to add color.

Термообработка

If your part is made from a heat-treatable aluminum alloy, you can heat-treat it to make it stronger and improve its mechanical properties.

Applications of Aluminum Machined Parts in Industry

Below are some of the industries that commonly use aluminum machined parts:

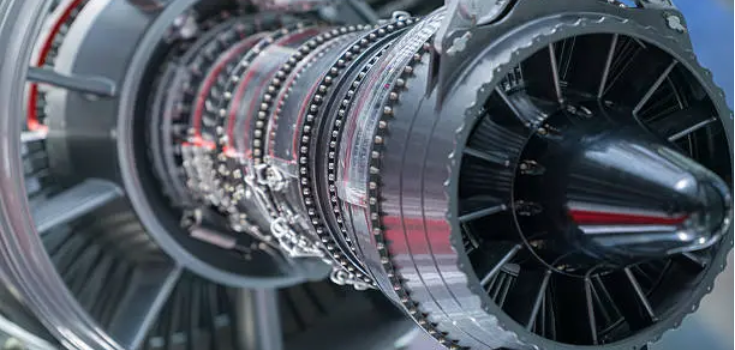

Аэрокосмическая промышленность

Aluminum CNC machined parts are strong, so they are perfect for making aerospace structural parts like engine components, airframes, and landing gear.

Since aluminum is lightweight, it reduces the weight of airplanes. CNC machined aluminum parts are also important for building parts like wing panels and fuselage sections.

Автомобили

In the automotive industry, CNC machined aluminum parts are used in engine components, suspension systems, transmission housing, and electric vehicle parts. Aluminum’s strength, durability, and light weight help reduce the overall weight of vehicles and improve their durability.

Бытовая электроника

Aluminum CNC machined parts are widely used in consumer electronics like laptops, smartphones, tablets, and audio equipment. Aluminum is ideal for making device casings because it is lightweight and provides protection for internal components.

High-end audio equipment such as amplifiers, headphones, and speaker enclosures often uses aluminum parts because it helps reduce vibrations and dissipates heat effectively.

What are Some Design Tips for Aluminum CNC Machining?

Here are some design tips to make sure your aluminum part is both functional and easy to make:

- Deep cavities can be hard to machine and may cause tool damage. Keep deep features to a minimum or split them into multiple steps for easier machining.

- Keeping the wall thickness uniform helps avoid wasting material or causing distortions. Too much variation can create weak spots or uneven stress.

- Sharp internal corners are hard to machine. Adding rounded edges helps make smoother cuts and reduces stress.

- Ensure that the cutting tool can access all parts of the design. Think about tool size and shape when designing features like holes or slots, so the tool doesn’t get blocked.

- Very thin walls can vibrate during machining and affect surface quality. Stick to a reasonable thickness for strength and stability.

- When adding threads to aluminum, make space at the bottom of the threads so the cutting tool can exit cleanly and produce high-quality threads.

- If your parts will have additional finishes like anodizing or bead blasting, make sure your design accounts for the extra material that may be removed or added during these steps.

Заключение

Now you know how CNC machining aluminum works and why it’s a good choice for many custom parts. You also understand the benefits of aluminum and how to design better parts of it.

At DEK, we can help you create strong, lightweight, and high-quality custom aluminum machined parts. Свяжитесь с нами now to get fast, reliable CNC machining services for your project.

Вопросы и ответы

How much does CNC machining aluminum cost?

The cost of CNC machining aluminum depends on factors like the type of aluminum, part complexity, and order size. Larger orders often reduce the cost per part by spreading setup and tooling expenses over more units.

Каковы альтернативы алюминию в обработке с ЧПУ?

If aluminum is not suitable for your project, you might consider other materials. Steel offers high strength but is heavier and more challenging to machine. Stainless steel provides excellent corrosion resistance.

Brass is easy to machine and has good corrosion resistance. Plastics like ABS or Delrin are lightweight and cost-effective for non-structural parts.

What factors should be considered when machining aluminum?

When machining aluminum, you should pick the right alloy for strength and corrosion resistance, use tools with sharp angles for easy cutting, and set the cutting speed and feed rate correctly to avoid tool wear.

Always use coolant to keep things cool and protect the tools, make sure chips are cleared away properly, and remember that aluminum can expand with heat, so plan for tight tolerances carefully.