You’ll run into aluminum bending if you work with metal parts, especially in buildings, cars, or machines. Aluminum is a great material, but it doesn’t always bend the way you want. If you don’t do it right, it can crack or lose its shape.

In this blog, you’ll learn how aluminum bending works, what can go wrong, and how to avoid problems. You’ll also see which aluminum types bend best and which bending methods give you better results.

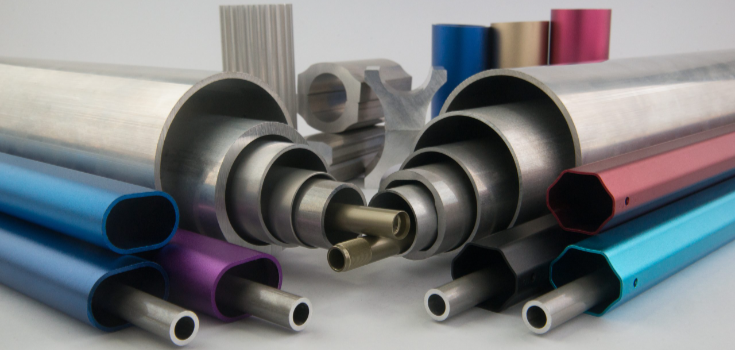

Overview of Aluminum and Its Alloys

Aluminum is a light, silver-colored metal that’s strong, resists rust, and is easy to shape. To make it even better for different jobs, other elements like copper or magnesium are added to create aluminum alloys.

These alloys are grouped into series, each with different strengths. For example, the 1000 series bends easily, the 3000 series adds strength and works well for things like cookware, while the 5000 and 6000 series are strong and great for building. Some, like the 7000 series, are very strong but harder to bend.

Factors Affecting the Aluminum Bending Process

There are some factors that may affect the bending process of aluminum, such as the following:

Aluminum Material Formability

Formability is how easily aluminum can bend without cracking or breaking. Aluminum alloys are usually good at bending, but some are easier to bend than others.

Level of Elongation

Elongation is how much aluminum can stretch before it breaks. Aluminum alloys with higher elongation levels are easier to bend compared to those with lower elongation.

Bend Radius and Aluminum Thickness

The thickness of the aluminum affects how much it can bend. Thicker aluminum and smaller bend radii need more force to bend. On the other hand, thinner aluminum and larger bend radii are easier to bend.

Best Aluminum Alloys for the Bending Process

Here are some aluminum alloys that you can bend easily:

3003 Series Aluminum Alloy

The 3003 aluminum alloy is one of the most commonly used alloys, mainly made with manganese. You can twist this alloy without heating it, so it is easy to bend into the right shape. It has the right qualities for easy forming.

You can use 3003 aluminum bending for:

- Roofing

- Chemical machinery

- Резервуары для хранения

- Sidings

5052 Series Aluminum Alloy

The 5052 aluminum alloy has more magnesium, so it is stronger than 3003. This strength helps it hold its shape even after bending. It also resists saltwater, which makes it ideal for use in salty environments.

You can use 5052 aluminum bending for:

- Hardware signage

- Marine tools

- Медицинское оборудование

- Гидравлические трубки

6061 Series Aluminum Alloy

6061 is the strongest aluminum alloy compared to 5052 and 3003, made with silicon and magnesium. Because it’s so rigid, bending this alloy is harder.

You can use 6061 aluminum bending for:

- Aerospace industries

- Автомобильная промышленность

- Структурные компоненты

Aluminum Bending Techniques

When you need to bend aluminum, there are different methods you can use depending on the shape of the material, and here are some common bending methods you can use:

Press Brake Bending Aluminum

To bend aluminum using a press brake, you first place the metal sheet between two tools called the punch and the die. Then, you set the angle and depth of the bend you want. After that, you turn on the press brake machine. The punch comes down and presses the aluminum into the die, bending it into shape.

Benefits of Press Brake Bending Aluminum

Press brake bending gives you accurate and clean bends. It’s also fast and works well when you’re dealing with large or thick pieces of aluminum.

Disadvantages of Press Brake Bending Aluminum

The equipment you need for press brake bending is expensive to buy or operate. It also may not be the best choice if you’re working with small or very thin pieces of aluminum.

Ram/Push Bending Aluminum

To bend aluminum with a ram or push tool, you first place the aluminum in a jig or fixture. Then, you activate the ram or push tool. The tool applies pressure to the aluminum, bending it into the shape you need.

Benefits of Push/Ram Bending Aluminum

Ram/push bending is great for making tight bends in aluminum.

Disadvantages of Ram/Push Bending Aluminum

This method may not work well for large or thick pieces of aluminum.

Roll Bending Aluminum

To bend aluminum using rolls, you first place the aluminum between the rolls. Then, you set the angle and depth of the bend you want. After that, you turn on the roll-bending machine. The aluminum is then passed through the rolls, which apply pressure and bend the metal into the shape you need.

Benefits of Roll Bending Aluminum

Roll bending is fast, consistent, and creates high-quality bends. It works well for bending large, thick pieces of aluminum.

Disadvantages of Roll Bending Aluminum

Roll bending requires special equipment, which can be expensive to buy or operate. It may also not work well for very small or thin pieces of aluminum.

Rotary Draw Bending Aluminum

To bend aluminum with rotary draw bending, you first place the aluminum between the mandrel and the die. Then, you turn on the rotary draw bender. The mandrel applies pressure to the aluminum, bending it around the die.

Benefits of Rotary Draw Bending Aluminum

Rotary draw bending can create aluminum with tight radii, accurate angles, and smooth transitions. It’s also good for bending large, thick pieces of aluminum.

Disadvantages of Rotary Draw Bending Aluminum

This method needs special equipment, which can be expensive to buy and run. It may also not work well for very small or thin pieces of aluminum.

Three-Roller Bending Aluminum

To bend aluminum using a three-roller method, you first place the aluminum between the rolls. Then, you turn on the three-roller bending machine. The aluminum is passed through the rolls, which apply pressure and bend it into shape.

Benefits of Three-Roller Bending Aluminum

Three-roller bending is great for making aluminum parts used in architecture or construction.

Disadvantages of Three-Roller Bending Aluminum

This process requires special equipment, which can be expensive to buy and operate. It may also not be suitable for very small or thin pieces of aluminum.

Compression Bending Aluminum

To bend aluminum with compression bending, you first place the aluminum between the punch and die. Then, you turn on the compression bending machine. The punch applies pressure to the aluminum, bending it around the die.

Benefits of Compression Bending

Compression bending helps you create aluminum products with bends that are the same on both sides.

Disadvantages of Compression Bending

The machine can be expensive to buy, and it may not work well for large or thick pieces of aluminum.

Stretch Forming Aluminum

To stretch form aluminum, you first place the aluminum in a jig or fixture. Then, you turn on the stretch forming machine. The jig or fixture applies pressure to stretch the aluminum into the shape you want.

Benefits of Stretch Forming Aluminum

This process lets you match the angle of the bend. The tension used during the process helps you maintain control over the entire length of the алюминий.

Disadvantages of Stretch Forming Aluminum

Specialized equipment is needed, which makes it expensive. It may also not be suitable for thin or small pieces of aluminum.

Hand Bending Aluminum

To hand bend aluminum, you first place the aluminum in the shape you want. Then, you use hand tools like pliers or hammers to apply force. The aluminum will bend into the desired shape.

Benefits of Hand Bending Aluminum

Hand bending is simple and inexpensive. You don’t need special equipment, and it’s perfect for small or thin pieces of aluminum.

Disadvantages of Hand Bending Aluminum

Hand bending is slow, so it might not be ideal for large or thick pieces of aluminum. Also, since it’s done by hand, the bends may not always be consistent, and each one could look different.

Temper to Use When Bending Aluminum

Tempering changes the strength and flexibility of aluminum alloys. Aluminum alloys come in different tempers, from soft and flexible to hard and brittle. Softer tempered aluminum alloys tend to spring back after bending, while harder tempered ones do not.

Here are some of the aluminum temper designations:

- “T” means it has been treated with heat.

- “H” means the alloy is hardened.

- “O” means the aluminum alloy is annealed (softened by heat).

- “F” means it has been fabricated.

How to Bend Aluminum Without Breaking It?

One of the best ways to bend aluminum without cracking is by heating it. When you heat the aluminum, it becomes more flexible, so it is easier to bend without breaking. Using the right bending tools is also important.

Here are some key tips for you to follow:

- Use lubricant on the bending area to reduce friction and prevent breakage.

- Make sure the bend radius is at least as thick as the material.

- Bend the aluminum across or diagonally to the grain if possible.

- Work slowly and apply even pressure as you bend.

- If you’re bending 6061-T6, consider annealing it first for better results.

Common Bending Problems and Solutions

In aluminum sheet metal bending, you may face a few common problems, and some of these include the following:

Cracking

Cracking is the most common issue you’ll see when bending aluminum sheets. This usually happens because of misalignment, smaller bending radii, too much tension on the surface, not enough pressure, or burrs left on the edges.

To prevent cracking, make sure to use holes or grooves to help the bending process go smoothly and avoid cracks.

Bending Interference

Bending interference happens due to the shape and size of the part and the die you’re using. To reduce this problem, pay attention to the bending die design, the sequence of bends, and the dimensions of the part.

Bending Indentations

Indentations can appear on the inner surfaces of the metal sheet. This happens when the press creates friction that leaves marks. To prevent this, use anti-indentation rubber balls or ball bearing dies, which will help by isolating the sheet from direct pressure.

Splits and Wrinkles

You might notice splits or wrinkles in the aluminum sheet. Splitting happens when the aluminum is bent too much, especially with thin sheets. To avoid this, check the thickness and bending radii before you start. Wrinkles happen when you apply too much stretch or compression. Be careful not to overdo it to prevent wrinkles.

Aluminum Bending Process

Here is how aluminum bending works:

- First, choose the right die and figure out how much you need to bend the sheet.

- Think about important things like how thick the metal is, how sharp the bend should be, how much space to leave for the bend, and how much force is needed.

- The most common dies you might use are 90° dies and sharp (acute angle) dies.

- Once you decide on these details, you can set up the CNC brake press.

- Depending on how complex the design is and the type of material you’re using, you might need to bend it in different ways.

- Pick the right die and tool; it’s very important for the machine to work correctly.

- Enter all the needed info into the CNC machine. This lets it check how much force is needed to bend the sheet.

- Place the flat aluminum sheet between the tool and die.

- Run the machine to bend the sheet the way you want.

- After that, take out the bent sheet and send it to the next step of the process.

Note: Most dies used to bend aluminum are made from strong materials like carbide or steel.

Applications of the Aluminum Bending Process

Here are some common ways aluminum bending is used:

Automotive components: Aluminum bending is used to create car body panels, fuel tanks, and other parts.

Строительство: In construction, aluminum is used for window frames, door frames, and other structural parts.

Аэрокосмическая промышленность: Aluminum bending is used to make airplane wings, fuselages, and other parts.

Мебель: Aluminum is used to make furniture like chair frames, tables, and other pieces.

Электрический: Aluminum is used to create electrical conductor bars and other electrical components.

Signs and Displays: Aluminum is often used for signs and displays because it’s lightweight and easy to shape.

Заключение

Knowing the right way to bend aluminum can help you avoid common problems and get better results in your work. At DEK, we can help with your custom aluminum bending needs. If you need reliable and high-quality aluminum bending services, feel free to get in touch with us.