If you’ve ever 3D printed a part, you probably noticed something right away, like some 3D printing bumps on surface, or some visible layer lines.

That’s where 3D printing surface finish becomes important. This blog will discuss the 9 methods to smooth 3D printed parts.

What is Surface Finish in 3D Printing?

Even if a surface looks smooth, if you look at it under a microscope, you’ll see tiny bumps and dips. This is called roughness.

There are a few ways to measure it:

Single roughness depth: The height between the tallest bump and deepest dip.

Average roughness depth: The average of five individual measurements.

Center roughness value (Ra): The average height of bumps and dips across the whole area.

In 3D printing, you usually use Ra (in micrometers) to compare surface smoothness. A lower Ra means a smoother surface. Surface finish in 3D printing is how smooth or rough the outside of a printed object feels. If the surface is really smooth, it’s called a fine finish. If it feels rough or bumpy, it’s a poor finish.

Usually, the part needs more work after printing, which is called post-processing. This helps improve how the surface feels and looks.

3D printing makes parts by adding layers on top of each other. Because of this, the surface can have tiny ridges and lines. To make it smooth, you’ll need to remove or reduce these lines carefully without damaging the part.

Why is 3D Printing Finishing Important?

Finishing your 3D printed parts is important for a few different reasons. Some of these reasons are:

For Aesthetics

A smooth or polished surface makes your part look better. You can control how shiny, smooth, or rough it is, and even improve the color and texture.

For Strength and Protection

Finishing can make your part stronger or more resistant to things like rust, heat, or wear. For example, metal parts can be coated so they don’t corrode or to help them conduct electricity.

For Functionality

Some parts need a certain surface texture to work right. For example, two parts that fit tightly together need a smooth surface. But in other cases, a rough surface helps, like when you want better heat transfer.

For Tolerance

Finishing helps you get the exact size you need. You might need to remove a bit of extra material or add a little to make the part fit just right.

What Affects Surface Finish in 3D Printing?

If you want a good surface finish, you need to understand what to adjust. Here’s what to look out for:

Type of 3D Printing

Different 3D printing methods give different surface finishes. If you use FDM, the print might look rough or have lines because it builds layer by layer. If you use SLS, the surface can feel grainy since it’s made from powder.

The Material You Print With

Not all materials work the same way. Some give a smoother finish, and others might look rough because of their texture or how they react to the printing process.

Printer Settings

How you set up your printer has a big impact on the surface finish. Thinner layers give you a smooth surface. Printing speed, curing, and infill settings also change how the print looks and feels.

Printer’s Quality

The quality and condition of your printer matter a lot. Cheaper printers usually don’t give you smooth finishes. If your printer is old or not maintained, it can lose accuracy.

How to Measure 3D Printing Surface Finish?

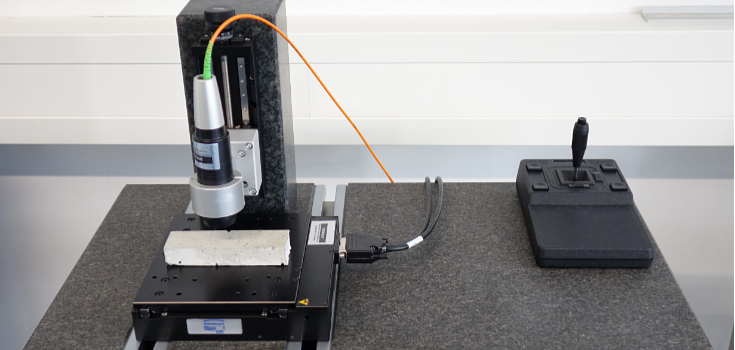

To measure the surface finish of a 3D printed part, you use a tool called a profilometer. It’s a very sensitive device with a tiny, pointed tip called a stylus that moves or slides across the surface of your print.

As it moves, the tip follows every little bump and dip on the surface. It records this shape, then the machine uses that data to calculate how rough the surface is, and this is how you get the surface finish value.

The most common way to describe this roughness is with a number called the Ra value. As mentioned earlier, this number is just the average height of all the tiny peaks and valleys the stylus recorded.

Common Methods to Improve 3D Printed Part Finish

Now, let’s go over some of the best ways you can improve the finish of your 3D printed parts. Check their details below.

Шлифовка

Sanding is the most popular and easiest method. You just rub sandpaper on your part to make the surface smoother. It removes rough spots, sharp edges, and little bumps by wearing them down.

It’s simple, cheap, and works well with most 3D printed materials. Sandpaper comes in different grits or levels of roughness. Start with coarse sandpaper to remove the rough parts, then use finer sandpaper to make it smoother.

But be careful not to sand too much or you might ruin the part. Sanding also takes time, so it’s not ideal if you’re trying to finish a lot of parts quickly.

The final surface will look matte. If you want it even smoother, you can polish it, or add paint or coating afterward.

Machining/Grinding

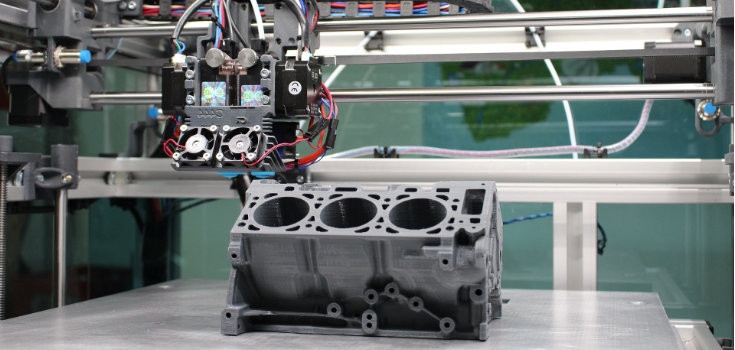

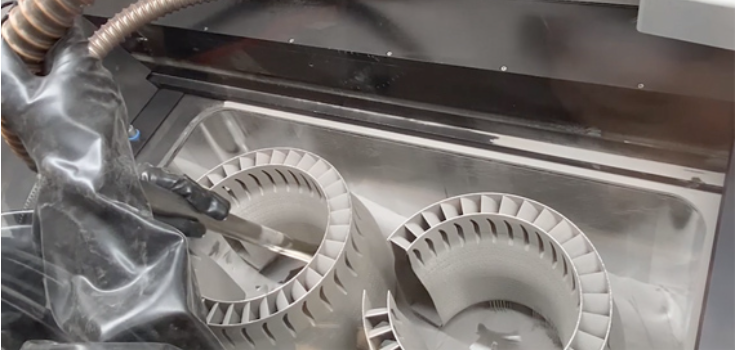

Even though 3D printing and Обработка на станках с ЧПУ seem like totally different technologies, they can actually work well together. You can use machining or grinding to improve your part after it’s printed.

This is great when you need very smooth surfaces or precise dimensions. Machining works really well in small or hard-to-reach places like inside holes or curved areas.

It also works with most 3D printed materials, whether you’re printing in plastic or metal.

Покрытие

Plating, also called electroplating, is when you add a thin metal layer to your 3D printed part using electricity.

It’s a great finishing method for both plastic and metal parts. If your part is made of plastic, plating makes it stronger, more durable, and able to handle more heat.

For metal 3D printing surface finish, plating can protect it from rust, improve electrical conductivity, and even make it easier to solder.

Plating is not just for strength, it also makes your parts look better. You can use shiny metals like gold, silver, or chrome to give your part a high-end, polished look.

Обработка бисером

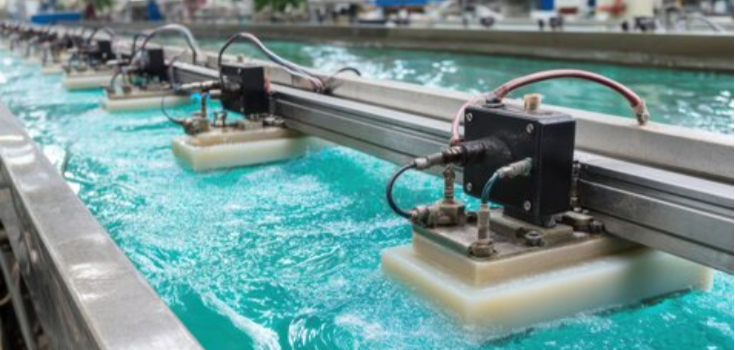

Bead blasting is another common way to smooth your 3D printed parts. It works by shooting tiny plastic or glass beads at the surface of your part. The beads hit the surface and help flatten out any rough spots.

It’s faster than sanding and can reach small or tricky areas that sandpaper can’t get to, like inside corners or holes.

You usually start with low pressure to see how much material is coming off. If everything looks good, you can slowly increase the pressure to get the best results.

But be careful, too much pressure can damage the part or take off too much material.

There are also other similar techniques like sandblasting, shot peening, and water blasting, which work in similar ways with slight differences.

Chemical Vapor Polishing / Vapor Smoothing

Vapor smoothing is different from other methods because it doesn’t physically rub or remove material. Instead, it uses a chemical vapor, like FA 326, inside a sealed chamber.

You place your parts in the chamber, and the vapor gently melts the surface just enough to smooth out the tiny bumps and dips. This creates a super smooth and shiny finish.

This process doesn’t damage your part and works really well if you want a high-quality, polished look. But keep in mind, it costs more than other finishing methods.

Media Tumbling

Media tumbling, also called tumbling or rumbling, is a method used mostly for small 3D printed parts. If your parts are around 200x200x200 mm or smaller, this method can work well.

You place your 3D printed parts into a tumbler machine filled with tiny ceramic chips. When the machine vibrates, the ceramic chips rub against the parts. This removes rough spots and makes the surface smoother.

This method is stronger than bead blasting and works well for materials like MJF or SLS prints. It’s a good option if you want to smooth out a bunch of small parts at once.

Живопись

Painting is one of the easiest and most familiar ways to improve how your 3D printed part looks. Just like painting anything else, it helps you get the color and finish you want– matte, glossy, or even metallic.

Before you paint, it’s a good idea to apply primer and putty first. These help smooth out the surface by filling small gaps and rough spots, so the paint sticks better and looks cleaner.

Painting also helps in another small way, as it can seal the surface a bit. While it’s not a full waterproof seal, it can help reduce porosity (tiny holes or gaps), which is a common issue with 3D printed parts.

Dyeing

When you dye a 3D printed part, the color goes deep into the plastic. But when you spray paint it, the color just stays on the surface.

Dyeing gives you brighter, longer-lasting colors and helps you avoid problems like peeling or scratching that can happen with spray paint.

Since dyeing does not add extra thickness, you won’t lose any small details. This is really important if your design is complex and detailed, and that’s often why you chose 3D printing in the first place.

A lot of people like to dye their parts black because it gives a clean, even look all over.

Which Materials are Suitable For 3D Printing with High Surface Quality?

Here are some of the materials that are best suited for high surface quality in 3D printing:

PLA (Polylactic Acid)

If you want easy and smooth 3D prints, use PLA. It’s one of the easiest materials to print with and gives you a clean, smooth surface right out of the printer.

PLA doesn’t warp much, so you can focus more on the design and less on print issues. It’s perfect if you’re printing models, decorations, or prototypes that need to look nice.

ABS (Acrylonitrile Butadiene Styrene)

ABS can give you a decent surface right after printing, but it really shines when you smooth it with acetone. That gives it a super glossy, professional look.

It’s strong and great for making parts that need to be tough. If you’re okay with doing a bit of post-processing, ABS can give you very clean results.

PETG (Polyethylene Terephthalate Glycol)

PETG is a good mix of strength and smooth surface finish. It gives you glossy, neat prints with better detail than ABS. It’s also easy to print and doesn’t warp easily.

ASA (Acrylonitrile Styrene Acrylate)

ASA is a lot like ABS, but it handles sunlight and weather much better. You’ll get a similar surface quality, and with some post-processing, it can look really nice. If you need something for outdoor use, get ASA.

Resin (SLA/DLP Printing)

If you want the best possible surface finish, you should try resin printing. It uses liquid resin and cures it with light, so the layers are super thin and almost invisible.

Your prints will look smooth and detailed, even with very small parts. This is perfect for miniatures, jewelry, and anything that needs a lot of detail.

Нейлон

Nylon can feel a bit rough when printed with SLS, but if you print with MJF or smooth it after printing, it can look really good.

Nylon is strong, and with the right finishing, you’ll get clean, professional-looking parts. It’s great for functional parts that still need to look nice.

PC (поликарбонат)

Polycarbonate gives you a shiny, clear finish, but sometimes shows layer lines more because it needs high heat.

If you tune your printer right, you can still get a smooth look. It’s very strong and can be used when you want both toughness and a nice finish.

DEK 3D Printing Services: High Quality Prototyping & Custom Parts

If you’re looking for high-quality 3D printed parts and surface finishing services, DEK is here to help you. Our team knows the right methods to get the perfect surface finish.

Plus, we give you 100% part inspection reports, so you can trust the quality of your parts. We also offer many machining services like CNC machining, milling, turning, and rapid injection molding.

At DEK, we’re experts in rapid prototyping and manufacturing, and we’ll support you through every step of your product development. Reach out to us today and get a free quote.

Заключение

This article is made to help you understand 3D printing surface finishes, and we hope it gives you useful information. But this topic is big and always changing as 3D printing keeps improving.

If you have more questions, you can always contact our experts.

Вопросы и ответы

Which 3D printing method gives the best surface finish?

That really depends on what you need it for. Every method has its own pros and cons and works best for certain types of products. If you just want it to look good, then painting or coating is a great choice.

But if your part needs to do something specific, like conduct electricity, you might want to use a material that can be electroplated.

Does 3D printing give a better finish than CNC?

Usually, CNC machining gives a smoother finish than 3D printing. But if you choose the right printer and finishing method, you can get pretty close to CNC-level smoothness.