You’ve probably run into this before, you start a print, and after a while, the corners begin to lift off the bed. That’s called warping. Warping is common, but it’s also preventable.

In this guide, I’ll walk you through the main causes and show you how to fix 3D print warping.

What is 3D Print Warping?

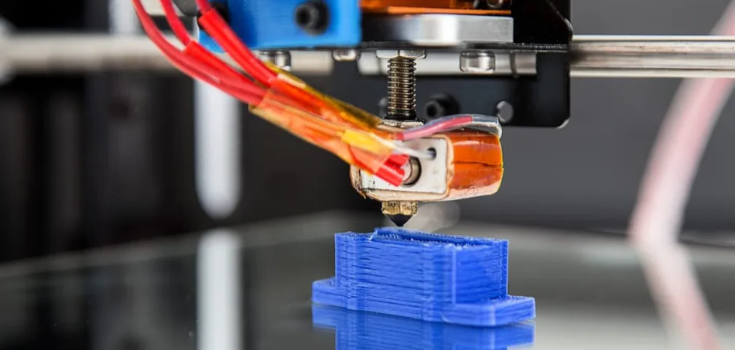

Warping is a common problem when you’re 3D printing with Fused Deposition Modeling (FDM). It happens when the bottom of your print starts to lift or curl up, and the corners come off the print bed. This makes your part look bent or misshaped.

Warping usually happens because the plastic cools down too fast after it’s printed. When it cools, it shrinks. If different parts of the print shrink more than others, it causes the print to warp or curl.

To understand warping better, think about how FDM printing works. First, a heated nozzle lays down melted plastic on a warm print bed. As the plastic cools, it hardens and gets smaller. This shrinking is called thermal contraction. If the cooling isn’t even or controlled, warping can happen.

Causes of 3D Print Warping

Below are the main reasons of 3D Print Warping:

Temperature Changes

When your 3D printer heats the filament, it expands. As it cools, it shrinks. If it cools down too fast or unevenly, your print can warp. This is the most common reason for warping. It usually happens when the cooling is not even, the airflow is poor, the fan is too slow, or you’re using the wrong type of filament.

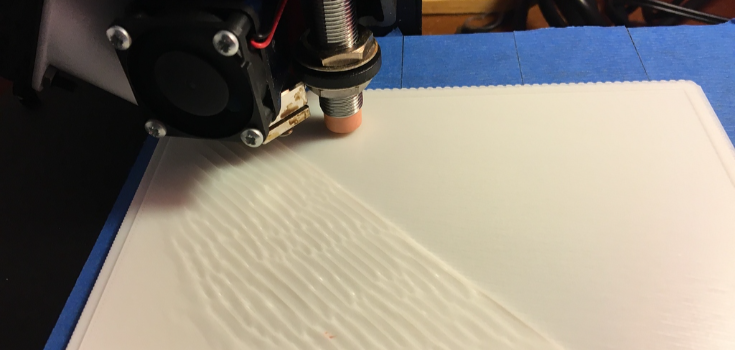

Bad Bed Adhesion

The first layer of your print has to stick well to the bed. If it doesn’t, the next layers might pull it up as they shrink. That’s when the print starts to warp. This can happen if your print bed isn’t level, if you didn’t use glue or tape, if the nozzle is too high or too low, if not enough filament comes out, or if the bed is dirty.

Wrong Slicer Settings

The slicer is the software that tells your printer what to do. If the settings are wrong, your print may not come out right. It can start lifting off the bed and warp. Make sure you’re using the right settings for your material, print speed, and design.

Printing Too Fast

If you print too fast, the filament might not stick properly. It can curl up instead of laying flat. Fast printing can also make the layers cool down too quickly and become weak. This can lead to warping. Slowing down the print speed usually helps.

Risks of Warping

Warping can mess up your 3D prints in a few big ways:

- It changes the shape and size, so parts might not fit or work right.

- It makes your part weaker and easier to break.

- It makes the surface look bad, with bumps or twists.

Materials Prone to Warping

Some 3D printing materials warp more than others. Let’s look at which materials warp easily and which don’t.

Materials That Warp Easily

ABS: ABS is popular and strong, but it warps a lot. If you don’t use a heated bed or enclosure, it cools too fast and curls up.

ASA: ASA is like ABS and great for outdoor use, but it also warps. You need the right bed temperature and an enclosed printer to control it.

Нейлон: Нейлон is strong and flexible, but it shrinks a lot as it cools. To reduce warping, use a heated bed, an enclosed chamber, and some bed adhesive.

PC (Polycarbonate): PC is super tough but needs very high print temps, around 300°C. Without good temperature control, the corners will lift, and the print may twist.

PP (Polypropylene): PP is durable but cools unevenly. You’ll need a heated bed and good cooling settings to keep it from warping.

Materials That Resist Warping

PLA: PLA is easy to print and doesn’t need much heat. You can often get good results without a heated bed. Just keep it out of the sun afterward, or it might still warp.

PETG: PETG is strong and prints around the same temperature as ABS, but it sticks better to the bed, which helps stop warping.

TPU: TPU is soft and flexible. It’s not likely to warp, but you’ll need the right settings to print it well.

Fiber-Filled Materials: These filaments have things like carbon fiber inside. They don’t shrink as much, so they warp less. But they can wear out your nozzle faster and need slower print speeds.

Differences Between ABS Warping and PLA Warping in 3D Printing

3D print warping depends on the type of filament you use. ABS и PLA have different properties, which affect how they warp.

PLA is stronger, stiffer, and has a lower melting point. It can warp easily during printing. After it sets, it becomes brittle, so it is harder for the layers to stick to the print bed.

ABS is lighter and less rigid than PLA, but it’s more resistant to heat. However, it tends to warp more than PLA. To print ABS successfully, use a heated print bed and set the nozzle temperature to 40-50°C.

How to Prevent 3D Print Warping

Warping can be hard to fix once it happens, so it’s important to prevent it before printing. It can also raise the cost of your 3D printing service. Here are some tips to help you get a smooth print:

Level the Print Bed by Doing a Paper Test or Print Test

Make sure the print bed is level. This keeps the nozzle at the right distance. If it’s too close, it can scratch the bed. If it’s too far, the filament might cool too much before sticking to the bed.

Heat the Print Bed and Head for the First Layer

Heating the bed and nozzle helps the filament stick better. For the first layer, increase the temperature by about 5°C, but adjust this based on the material you’re using.

Use a Heated Enclosure

A heated enclosure keeps the temperature steady and helps prevent warping by reducing shrinkage. Not all printers have this, but you can make one yourself.

Use a Raft or Brim

A raft is an extra layer attached to the first layer to help it stick better. A brim adds a ring around the model to improve adhesion, too.

Adjust the Slicing Settings

Try increasing the first layer’s height to increase the surface area and improve adhesion. You can also expand the first layer’s line width to add more pressure, which can help reduce curling.

Reduce Printing Speed

Slower printing gives the filament more time to adhere to the bed and cool evenly, which can prevent warping and curling.

Turn Off the Cooling Fan for the First Layers

Cooling fans cool the filament quickly, which can cause warping. Turning off the fan for the first layers keeps them warm and helps them stick to the bed.

Clean the Print Bed

Dirt and dust can lower the adhesion of the filament to the bed. Clean the bed before printing for better results.

Use Adhesives

You can use glue, blue tape, or other adhesives to help the filament stick to the bed. Just make sure the adhesive works with your filament and doesn’t affect the print quality.

Заключение

3D printing warping happens when different parts of the print cool at different rates, causing the material to bend or shrink. This is a common issue, but it can be prevented. In this guide, you must have learned what causes warping, how to fix it, and how to stop it from happening.

At DEK, we offer affordable, top-quality 3D printing and CNC machining services. Our company is ISO certified, ensuring we meet high standards of quality. Our experienced team uses the latest equipment to provide the best service. Свяжитесь с нами today to see how we can help with your 3D printing needs.

Вопросы и ответы

Does print orientation affect 3D print warping corners?

Yes, how you position your print can make warping worse. Some angles or shapes can cause the corners to lift. Try changing the direction of your print to reduce warping.

Is my print bed causing 3D print warping on one side?

It’s possible. If the bed isn’t level or is uneven, it can cause one side of the print to cool differently, leading to warping. Make sure the bed is clean and level before printing.

Can resin 3D print warping occur?

Yes, resin prints can warp, but it’s less common than with filament prints. Warping can happen if the resin cures too fast or unevenly. Make sure your settings are right, and use support if needed.

Is an enclosure necessary to stop ABS 3D print warping?

An enclosure helps stop ABS from warping. It keeps the temperature steady, so the print doesn’t cool too fast and shrink. It’s not absolutely necessary, but it can make your print more successful, especially with bigger projects.