Medical prototypes often involve micro-scale geometries, tight fits, sharp internal corners, and strict biocompatibility. Polished surfaces and burr-free edges are essential to pass clinical validations.

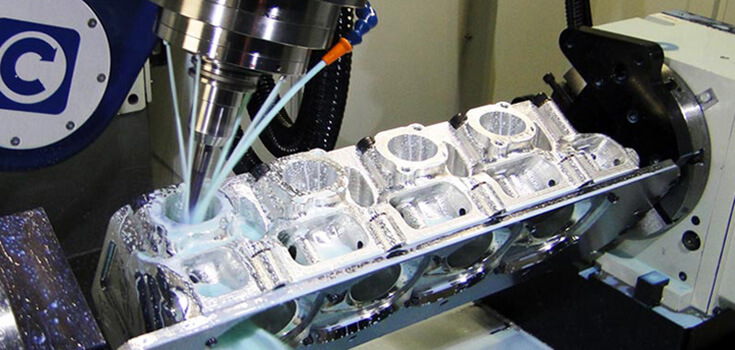

DEK applies 5-axis CNC, micro-milling, and EDM to handle complex contours and narrow slots. Our ISO 13485-aligned workflows and FDA-compliant materials ensure biocompatibility and traceable process control.

All parts are inspected using CMM, vision measurement systems, and laser micrometers to ensure every feature meets design intent before clinical testing.

Medical prototypes often require channels or details <1mm. We apply micro-end mills (0.2–0.5mm), reduced tool chatter, and controlled spindle RPM to maintain dimensional accuracy within ±0.01mm.

Prototypes like orthopedic implants often require compound curves and undercuts. We use simultaneous 5-axis setups to reduce repositioning error and achieve accurate multi-face geometry in a single clamping.

For contact surfaces, Ra 0.2μm is achieved through mechanical polishing and passivation. This improves biocompatibility and visual inspection. Internal burrs are removed via ultrasonic cleaning.

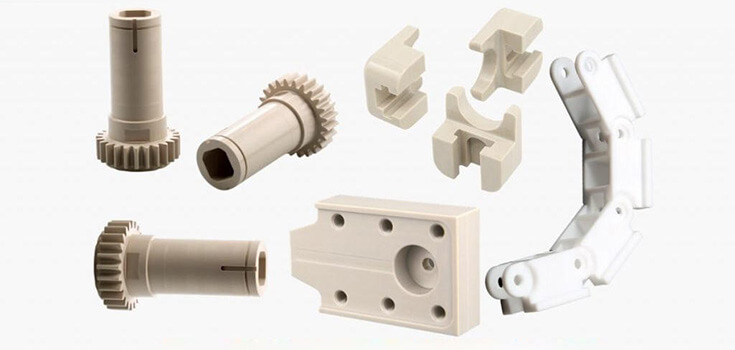

Materials like PEEK, Ultem, or medical-grade Nylon require sharp tools and thermal control. We pre-dry, use high rake angles, and ensure no burning or warping on thin-walled parts.

We can machine M1–M3 threads with precision taps and inspect with go/no-go gauges. Insert installation is also supported with force validation and retention tests.

DEK обеспечивает точность, скорость и бездефектное производство, которым доверяют инженеры-механики при решении самых ответственных задач.

Присылайте нам свои чертежи - мы быстро предоставим обратную связь DFM и точное предложение, без минимального заказа.