- Startseite

- Ressourcen

- Was ist SFM in der Zerspanung: Definition, Berechnung und Einsatzmöglichkeiten

What is SFM in Machining: Definition, Calculation, and Uses

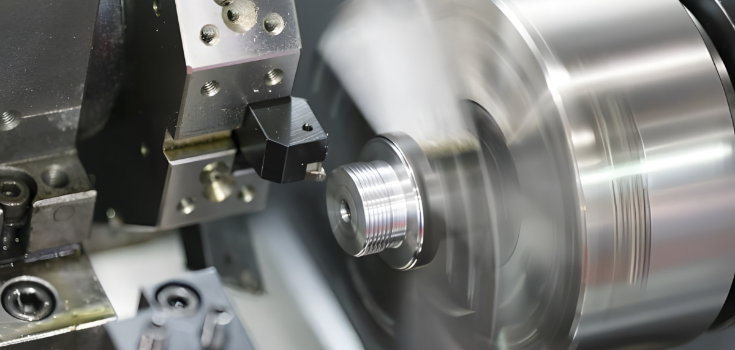

If you’re working with machines that cut metal or other materials, you need to know what is SFM in machining. It’s an important number to get your cutting just right.

This guide will let you know what does SFM mean in machining. You’ll learn how to calculate it, why it is important, and how to use it in different machining jobs.

What is SFM in Machining?

“SFM” means surface feet per minute. This is a very important measurement. It shows how fast the edge of a cutting tool moves across the surface you are working on. It helps you know the best speed to use for cutting different materials with different tools.

The Importance of SFM in Machining

These are the main reasons why SFM matters in machining:

- If the speed is too high, it creates too much heat and wears out the tool faster. If you pick the right speed, your tool stays in good shape longer and doesn’t have to be replaced as often.

- Using the right SFM helps you remove material quickly and work more efficiently. It controls how the tool touches the workpiece, which helps form chips properly and makes the job faster. The right speed means you get more work done with better accuracy.

- If the speed is too low, the tool rubs and makes a rough surface. If it’s too high, the heat can damage the workpiece. The correct speed gives you a smooth, clean finish with less tool vibration.

- Too fast SFM creates too much heat, causing the material to change shape. Too slow SFM causes heat to build up. Using the right speed with good cooling keeps the temperature balanced and prevents overheating.

SFM Formula and Calculation

You can calculate SFM using the tool’s spinning speed and size.

Key parts you need:

Spindle Speed (RPM): How fast the tool spins (revolutions per minute).

Cutter Diameter (D): The width of your cutting tool, measured in inches.

The formula is:

SFM = (RPM x 𝜋 x D) / 12

RPM: Spindle speed

D: Cutter diameter in inches

𝜋: About 3.14159

12: Converts inches to feet

If you spin faster (higher RPM) or use a bigger tool, the SFM goes up. But you must choose the right speed for your material and tool to avoid problems like too much heat or breaking the tool.

Convert SFM to millimeters per minute (MM/min)

MM/min = SFM x 0.3048

Convert RPM to SFM

For Milling:

SFM = RPM ((Tool Diameter x 𝜋) / 12)

For Turning:

SFM = RPM ((Workpiece Diameter x 𝜋) / 12)

Common Mistakes to Avoid

Always double-check your calculations and use trusted sources for SFM and RPM values. Here are the common mistakes you need to avoid:

- Mixing up units when converting

- Using old or incorrect tool data

- Ignoring the right SFM for your specific material

Using SFM Calculators and Charts

You don’t have to do the math every time you machine something. You can use SFM calculators or charts to make things easier. These tools are found online, in machining apps, or even in tool catalogs.

Just enter your tool size, and the calculator will convert SFM to RPM for you. It gives you the answer quickly without guessing. Charts are also helpful. They list recommended SFM values

For different materials like Aluminium, steel, or titanium. You just look up your material, find the SFM, and then calculate the right RPM for your tool.

Using these tools saves you time, helps you avoid mistakes, and makes your work safer and more accurate.

Here are some of the helpful tools you can use:

- Machinist’s Calculator

- Online SFM Calculators

- CNC Machine Software

Units and Standards for SFM

SFM can be measured in different units depending on the system you use. Knowing these units helps you read charts, use calculators, and follow instructions correctly for machining.

Imperial (FPM) vs Metric (m/min) in SFM

There are two main unit systems you will see:

Imperial System: Used mostly in the U.S., SFM is measured in feet per minute (FPM). This means how many feet your cutting tool moves over the material each minute.

Metric System: Used in Europe, Asia, and many other places, it measures speed in meters per minute (m/min). It’s the same idea but uses meters instead of feet.

To convert between them:

- Multiply feet per minute by 0.3048 to get meters per minute.

- Multiply meters per minute by 3.281 to get feet per minute.

Industry Standard SFM Speeds for Different Materials

Different materials need different cutting speeds. Some materials are soft and can be cut fast. Others are hard and must be cut more slowly to protect your tool. Here are some general speed ranges in feet per minute (FPM) that are a good starting point, but can change based on tool type, coatings, cooling, and machine power:

Aluminium: 300-1000 (soft, cuts fast)

Unlegierter Stahl: 100-300 (stronger, cuts slower)

Rostfreier Stahl: 50-200 (hard and tough, cuts slower)

Titan: 30-70 (very hard, cut slowly to reduce heat)

Kunststoffe: 500-1500 (cuts easily, but heat can melt them, so control speed)

Factors Affecting SFM Settings

The CNC tools you choose have a big effect on how you calculate and use SFM when machining. Different tools work in different ways, so the best SFM will change depending on what you’re using.

Cutting Tool Material

High-Speed Steel (HSS): If you’re using HSS tools, they’re tough and flexible, but you need to run them at lower SFM to avoid wearing them out too fast.

Carbide Tools: These can handle more heat and faster cutting, so you can use higher SFM, and speed up your work.

Ceramic and Cement Tools: These are made for high-speed cutting, especially on hard materials. You can run them at much higher SFM than HSS or carbide tools.

Werkzeug-Geometrie

Tool Diameter: If you’re using a larger diameter tool, you’ll need to lower the RPM to get the same SFM as a smaller tool. This affects your cutting speed and how efficient the process is.

Flute Design: The shape and number of flutes on your tool change how it cuts. More flutes usually mean you can use a higher SFM, but you might need to change your feed rate to match.

Werkzeug-Beschichtungen

Coated Tools (like TiN or TiAIN): These coatings reduce friction and help the tool resist heat. If your tool is coated, you can usually run it at a higher SFM than if it weren’t.

Uses of “SFM” in Machining Processes

Here’s how SFM works in different machining processes:

SFM in Milling

When you mill parts, like big shafts, using the right SFM lets you remove material faster. A higher SFM means you can finish the part quicker, which helps you get more done in less time.

SFM in Turning

If your speed is too high during turning, the tool can get too hot and ruin the surface. If it’s too low, the surface comes out rough. So, you need to set the right SFM to keep your tool working well and get a smooth finish.

SFM in Drilling and Boring

When drilling into hard materials like steel, the right SFM keeps the drill bit from wearing out too fast. In parts like engine blocks, where the hole size has to be exact, using the correct speed helps you drill smooth, accurate holes.

SFM in Grinding

If you’re grinding, the correct SFM helps the grinding wheel last longer. For example, when grinding steel shafts, the right speed keeps the wheel sharp and reduces wear, so it works better for longer.

Is SFM the Same as RPM?

No, SFM and RPM are not the same. SFM (Surface Feet per Minute) tells you how fast the cutting edge moves across the surface of the material. RPM (Revolutions per Minute) tells you how fast the tool or spindle is spinning.

What is the Relationship Between SFM and RPM?

SFM and RPM work together, and the size of your cutting tool affects the connection between them. So, if you spin the tool faster (higher RPM), or use a bigger tool (larger diameter), the SFM goes up.

Schlussfolgerung

SFM is something important you need to get right based on your material, tool, and machine. When you get it right, everything runs better: your tool lasts longer, your parts look cleaner, and your whole job gets done faster.

Unter DEK, we know how to match the right cutting speed (SFM) with the right tool and material. This helps us give you smooth surface finishes, high accuracy, and fast turnaround times. We use our CNC machining skills to give you quality results that fit your needs and budget. Contact us today and get a free quote.