- Startseite

- Ressourcen

- Snap Fit Joints: Types & Benefits

Snap Fit Joints: Types & Benefits

Assembling mechanical components requires using snap-fit joints, which ensure the parts are tightly fitted together. Snap-fit joints are widely used in many applications, and they have different types as well.

If you are looking to have hands-on snap-fit joints and want to know more about them, read the guide below.

What is Snap Fitting?

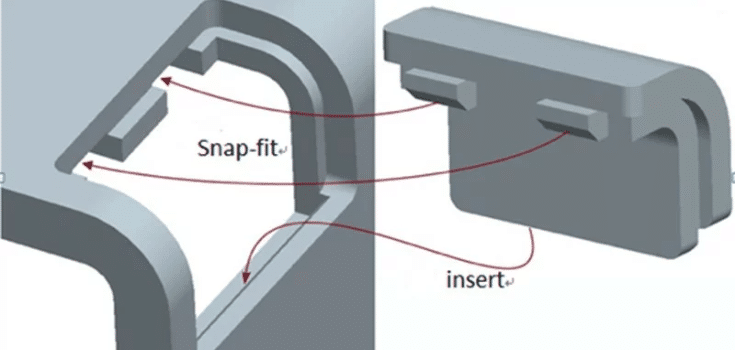

Snap-fitting is a mechanical assembly in which the components are joined with one another. The components joined are usually the mating parts, and they have flexibility; such components are made of plastic.

The required fit is achieved by pressing one component into another, and they are snapped and locked together.

Types of Snap Fit Joints

There are different types of snap-fit joints, and some of these are discussed below:

Cantilever Snap Fit Joints

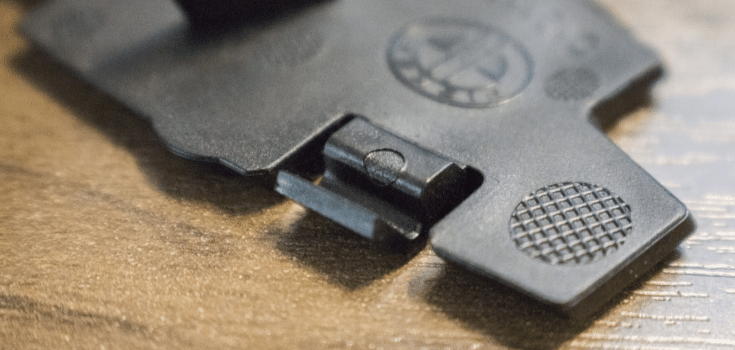

Cantilever snap-fits are a very common type of snap-fit consisting of an interlocking feature and a cantilever arm.

It is assembled by passing the arm of the component into the cavity of another component. The arm is deformed, and the components are snapped together.

This type of joint is very durable. However, hyper-extension must be avoided so that the arm doesn't lose its ability to come back to its original shape.

Annular Snap Fit

An annular snap-fit joint consists of a hoop that is circular, and it expands when it is pushed in the matching groove. This extension creates stress in the annular hoop and creates a force of friction that holds it on the groove structure.

The snap fitting is suitable for high-stress applications and distributes stress uniformly.

Torsion Snap Fit

Torsion snap fit is very much identical to cantilever snap fitting as they also have cantilever arms with interlocking clips. The arm, however, stays at its actual position due to the torsional force.

In order to assemble and disassemble this snap-fit, the spring force must act against and relieve the interlocking clip.

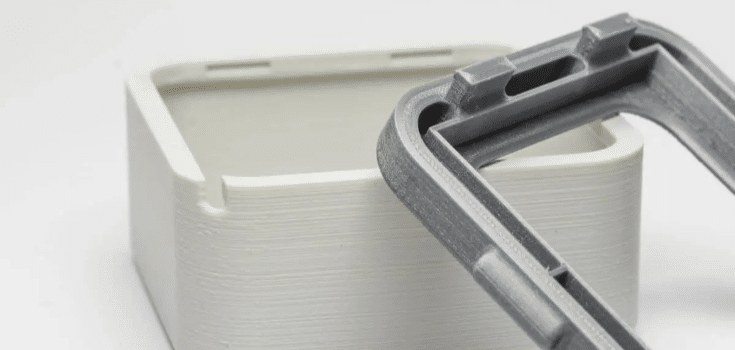

U-Shaped Snap Fit

The u-shaped snap fit is a u-shaped interlocking element that has a cantilever arm folded within itself. The arm bends when the components are assembled or disassembled, and there is a clip that interlocks the components.

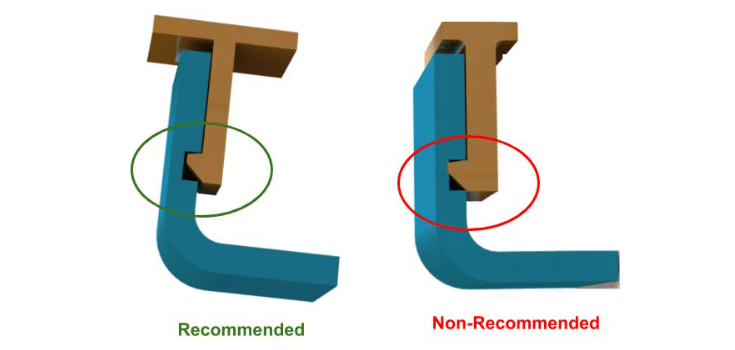

This snap-fit design is very useful but prone to hyperextension due to the different stress concentration points.

Benefits of Snap Fit Joints

Snap-fit joints have multiple benefits, and some of these are discussed below:

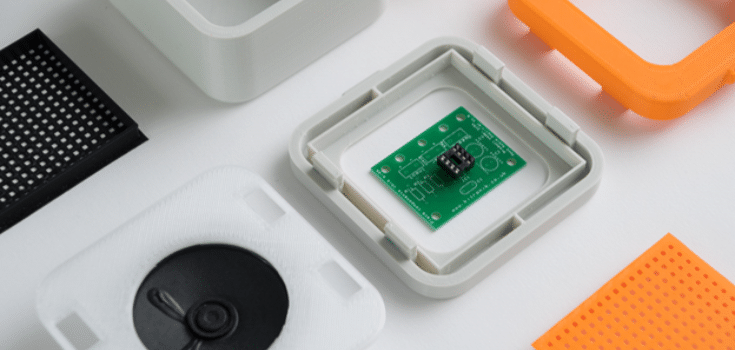

- Snap-fit joints are very easy to assemble and disassemble, taking less time with no tools or special equipment required.

- Snap-fit joints create mechanical joints on their own without any need for washers, screws, and nuts.

- Snap-fit joints are long-lasting and do not need repeated replacement if used appropriately.

- Other types of mechanical fasteners do not look good, but snap-fit joints offer an aesthetic appearance.

Limitations for Using Snap Fit Joints

Snap-fit joints have some limitations along with the benefits, and these are given below:

- Snap fit joints are composed of stress concentration areas and interlocking characteristics, which makes it difficult to manufacture them.

- Due to their complexity, the cost of manufacturing is high.

- Snap-fit joints consist of flexible parts that are easy to break.

- Snap-fit joints are temporary joints and are not as durable as nuts, bolts, and screws.

Common Issues with Snap Fit Design

There are some issues with the snap-fit design that must be kept in mind when implementing it for a joint. Some of these are discussed below:

- The problem of stress concentration is prevalent in the snap-fit design, and the smaller area has more stress than the other part. This high stress may impact the snap-fit joint and lead to breakage.

- Snap-fit joints are under load for an extensive period of time, which makes the material weak and can lead to creeping.

- A snap-fit joint is consistently assembled and disassembled, which leads to the weakening of the structure and fatigue in the joint.

- Environmental factors may impact the performance of the snap fit joints, such as chemical exposure, humidity, and high temperature.

Practical Tips for Designing Durable Snap Fit Joints

The tips for designing durable snap-fit joints require some design calculations, which are discussed in this section below.

Symbols

Some of the important symbols for the design calculations are as follows:

- b= width at the root

- y= permissible deflection

- c= center of gravity

- L= length of arm

- E as absolute value = percentage/100

- h= thickness at the root

- K= geometric factor

- P= permissible deflection force

- Es- secant modulus

- Z=Ic where l is the axial moment of inertia

- Z= section modulus

Cantilever Snap Fit

The design calculations for the cantilever snap fit are as follows:

Permissible Undercut

Undercut = b h/2

Where b is the width at the root and h is the thickness at the root.

Maximum Strain and Stress

Maximum stress = σmax = M c/l

M = P.I

Σmax = (P.I.2h)/l

Maximum Strain = ϵmax=σmax/E

E= Material’s Elastic Modulus

σmax = maximum stress

Deflection Force and Mating Force

Deflection = (3.E.I.y)/l3

Fmating = Deflection x (1+friction factor)

Torsion Snap Fit:

Deflection

θ= Txl/GxJ

Deflection Force

T= θxGxJ/l

Annular Snap Fit

Permissible Undercut

Permissible Undercut= (σallowxAroot)/Applied Load

Mating Force

Fmating = T/R

How to Manufacture Snap Fit Joints

Die manufacturing process for snap fit joints is given below.

- The first stage is creating the design in detail, which is based on the functionality. Before manufacturing the entire volume at once, a prototype can also be manufactured.

- Material selection is also important once you have finalized the design. Snap fasteners can be made using versatile materials, including metals and plastics.

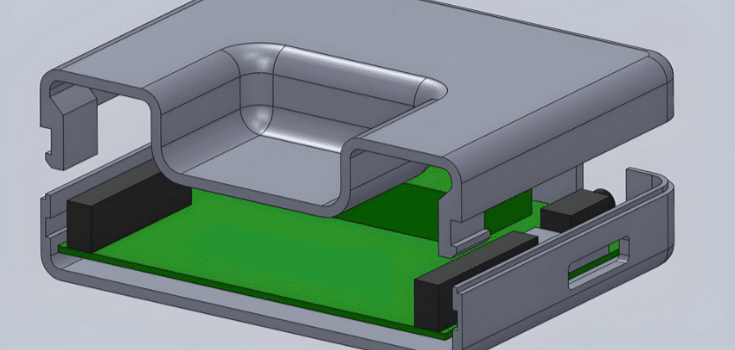

- Snap fasteners can be manufactured using different processes like stamping as well as injection molding based on material compatibility.

- When you have attained the required shape of the snap fastener, a corrosion-resistant plating is applied so that its life can be enhanced.

- Once the snap fasteners are manufactured, they are assessed for quality inspection to check if the components fit exactly with one another or not.

How to Install and Maintain Snap-fit Joints

The process of installing snap fasteners is as follows:

- Consider the dimensions of the snap-fit joint to ensure that it is suitable for the required application and check its features and tolerance.

- Align both the components to be mated properly so that the components can fit with one another perfectly leading to no misalignment.

- When you have aligned the components, apply some force and fix the components.

Some considerations for maintenance of the snap fasteners are as follows:

- Regularly inspect the snap fasteners to check for any deformation or gap due to heavy loads.

- In case they catch any contaminants or dirt, clean them.

- If there is any damage to the snap fasteners, immediately replace them so that the structural integrity is maintained.

- Do not apply any excessive force as it may lead to breaking the joints.

Applications of Snap Fit Joints

Snap fasteners are widely used in many industries as they cater to a lot of applications. Some of its applications are as follows:

Autoindustrie: In the automobile industry, snap fasteners are used for assembling headlights, dashboard components and trim panels.

Medizinische Industrie: In the medical industry, syringes, diagnostic devices, and many other medical equipment can be assembled using snap fasteners as they help with proper sterilization.

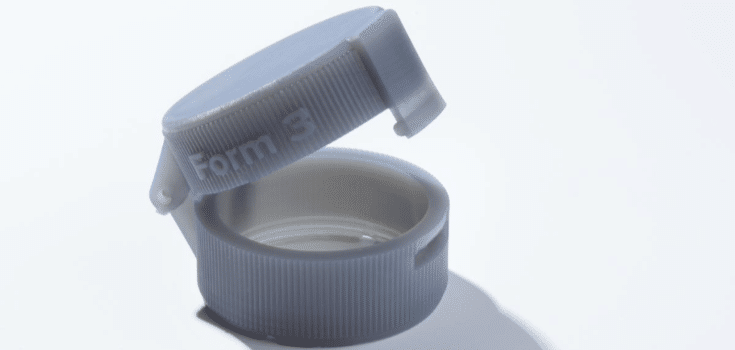

Packaging Industry: The packaging industry uses snap fastener joints to seal the enclosures and container lids and ensure design integrity.

Schlussfolgerung

Snap-fit joints are crucial for a lot of components that need assembling, and they can offer effective and durable joints.

If you are looking for high-quality snap-fit joints manufactured using various materials, DEK can be your go-to choice for future projects. We offer manufacturing custom snap-fit joints that are according to your products and applications.

FAQs

What are the main parts of a snap-fit joint?

The two main parts of snap-fit joints that mate together are the snapper and receptor.

What are the common processes used to produce snap-fit joints?

The common processes for producing snap-fit joints are injection molding, 3D printing, and CNC machining.

Is metal compatible with snap-fit joints?

Yes, in high-stress applications, metal is highly compatible with snap-fit joints.

What materials work best for cantilever snap fit joints?

There are different types of thermoplastics suitable for cantilever snap-fit joints, like polypropylene, ABS, and nylon.

What are the correct tolerances for snap-fit design?

A snap-fit design has no specific tolerances, but it can range between 0.2 to 0.5 mm.