- Startseite

- Ressourcen

- Sheet Metal Part Drawings: Design and Fabrication Guidelines

Sheet Metal Part Drawings: Design and Fabrication Guidelines

Sheet metal drawings show how and what to do to fabricate any type of sheet metal part properly. They are extremely useful in guiding manufacturers with all dimensions, specifications, and tolerances needed for proper and accurate production.

Design rules are important guidelines to ensure that components satisfy the specification and are readily amenable to high-quality manufacture. This article sets out to look at the principles, processes, and practices that apply to sheet metal drawings.

What are Sheet Metal Drawings?

Sheet metal drawings are a more elaborate description of a mechanical drawing pertaining to the shape, dimensions, and specifications of sheet metal components. They communicate the design intent to manufacturers, indicating things like bend lines, hole positions, surface treatments, and tolerances.

Such drawings will enable turning flat metal sheets into finished parts through cutting, bending, and forming. Accurate sheet metal drawings serve as a blueprint for milling and turning. CNC machining ensures precision and consistency across production runs.

Importance of Sheet Metal Drawings

Reduce Errors and Minimise Rework

With correct implementation, clear drawings for a part ensure it is produced as intended. Thus, minimizing production errors, rework, and, more importantly, losses. This further reduces production risks and confirms that the manufactured part fits within the original design intent.

Guide Milling, Turning, and CNC Operations

Give precise specifications for machining processes. For instance, every cut, hole, and bend is made accurately. Such guidance enables machine operators to uphold consistency between various production batches.

Ensure Proper Assembly and Fit

With precise dimensions and tolerances, one can reduce the chances that parts will be misaligned during assembly. This assures that components can function together smoothly without forcing admissibility into adjustments themselves with modifications.

Define Material, Tolerance, and Surface Finish

All processes should define the material in terms of type, thickness, and finishing. After that, the quality of the part remains assured. These specifications help manufacturers select applicable processes in order to achieve Stärke and good visual quality.

Facilitate Communication Between Teams

The documents should serve as a general reference for designers, production men, and quality control. This shared understanding minimizes confusion and supports seamless coordination between departments.

Maintain Efficiency and Part Quality

Promotion of good sheet metal design rules helps to check delays in production. Wasted materials while at the same time assuring a consistent high quality of components. Efficiency directly improves timelines in delivery and serves overall manufacturing reliability.

Sheet Metal Drawing Process

The method of making drawings for sheet metal parts consists of designing these drawings through several key steps:

Gestaltung

Produce your part layout on the CAD package. This includes all features, bends, holes, and cutouts. An unambiguous digital layout confirms that the manufacturer understands every functional detail before production begins.

Auswahl des Materials

Sheet thickness and type should be chosen on the grounds of strength, machinability, and part function. Right material selection also controls cost with durability and long-term performance.

Werkzeugkonstruktion

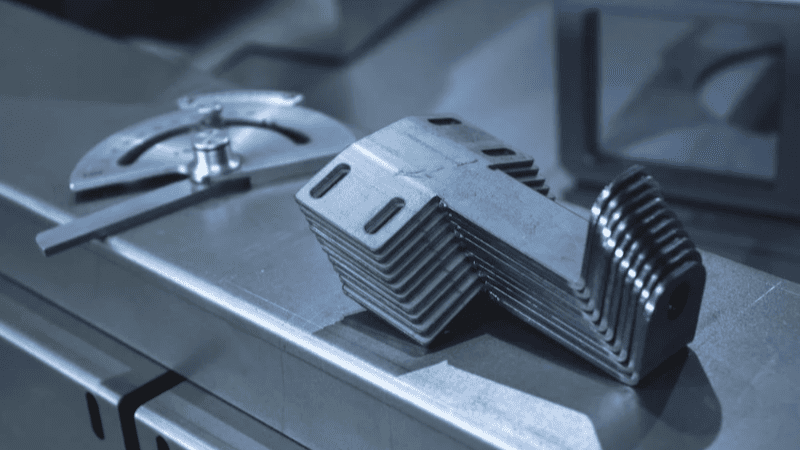

Identification of necessary dies, punches, and fixtures for forming and bending. Proper tooling planning prevents deformation issues and assures accurate repeatability.

Ausblendung

This means to make the flat sheet stock to size and specification. Accurate blanking reduces waste and improves efficiency downstream in forming.

Bildung von

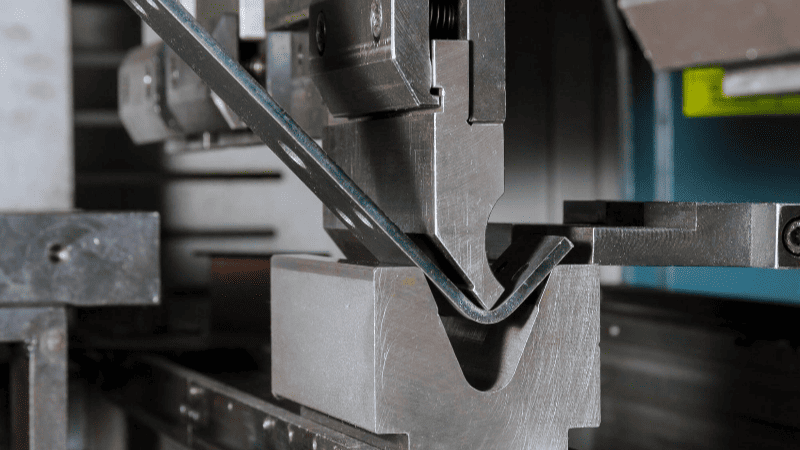

Sheet metal is formed using press brakes, stamping, or CNC machines. By carefully controlling the forming process, dimensional stability is ensured, while the chances of cracking or warping are reduced.

Trimming & Finishing

Remove any unwanted materials and apply surface treatments and/or coatings where necessary. Finishing improves both aesthetics and resistance to corrosion and serves to enhance the longevity of the part.

Each stage should be represented in the drawing to ensure the part can be produced efficiently and consistently. Clear documentation helps your manufacturer avoid mistakes and achieve stable, high-quality output.

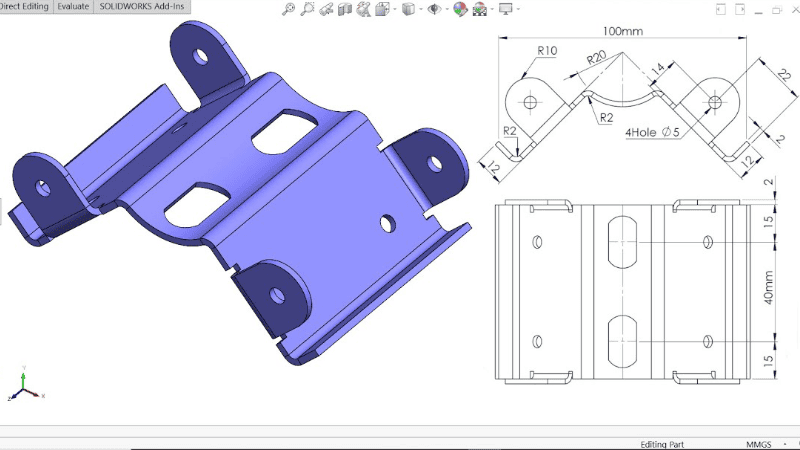

Sheet Metal Dimensional Drawing Example

A good sheet metal dimensional drawing contains the following:

- Overall dimensions.

- Bend locations and angles.

- Positioning of holes, with diameters.

- Cutout patterns.

- Tolerances.

- Type and thickness of material.

- Surface finish requirements.

For example, in the case of a bracket design intended for CNC machining, providing the actual hole-to-bend dimensions. These bend allowances can guarantee that any CNC milling or turning process will be accurate and need no rework.

What Your Sheet Metal Drawings Should Include

To make thorough sheet metal part drawings, include the following:

Part Geometry: Show all edges, bends, and shapes.

Material Specifications: Type, thickness, and hardness of material.

Dimensions and Tolerances: Critical dimensions and permissible variation.

Bend Allowance and Deduction: Indicating material stretch and springback.

Feature Annotations: Hole types, countersink, slots, and flanges.

Surface Finish Requirements: Details on coatings, polishing, or powder coating.

Assembly Instructions: Unless the part interfaces with other components.

Bill of Materials (BOM): Listing of all parts necessary for assembly.

Revision Information: Trace all changes made to the part.

Title Block: Company information, part number, scale, and date.

Views and Sections: Include orthographic, isometric, and flat pattern views.

Notes and Annotations: Further instructions for manufacture or inspection.

The inclusion of these features guarantees compliance with sheet metal design laws, providing for a straight manufacturing practice.

Drawing Formats

To specify clarity and utility, it is extremely important to provide a set of drawing formats:

2D PDF Drawings

All dimensions, annotations, and flat pattern views are described. Drawings become primary references for fabrication, coming together to aid machinists so that the project is clear in every respect. These would also assist in the verification of measurements and tolerances during inspection by the quality teams.

3D CAD Files

These STEP/IGES files aid in CNC simulation and nesting. Provide trustworthy geometry for machining, Biegen, and assembly verifications. Also reduces any chance of misplace through provision to view complex shapes from all angles.

DXF Files

Flat pattern outlines that aid laser cutting or CNC punching are contained in DXF files. The data contained in the DXF files allows for precise profiles. These allow the optimization of cutting paths, thereby minimizing cycle time. More importantly, they are also capable of nesting material well enough to cut scrap and maximize cost savings.

Ensure that all files are well-labeled and controlled in terms of version with respect to time, so that the manufacturers refer to the right version at the time of production.

Purpose of 2D Drawings in the Sheet Metal Drawing Process

The other applications of a 2D sketch in sheet metal fabrication include:

- Properly communicating a design intent to manufacturers.

- Providing flat patterns for CNC cutting, milling, and turning.

- Detailing the bend lines, holes, and assembly interfaces.

- Enabling accurate cost estimation and material planning.

- Serving as a reference for the quality inspection.

The possible errors in sheet metal fabrication would then be minimized. Fast-tracked production is then ensured while maintaining dimensional accuracy through the combination of 2D drawings with 3D drawings.

Tips for Creating Better Sheet Metal Part Drawings

Ensure Design Precision

The dimensions and tolerances need to be very precise for dependable sheet metal parts to be manufactured. Minor variations can become annoying when assembling parts or put off milling, turning, and CNC.

So, check all measurements yourself for alignment purposes, radius sizes for all bends, and hole placements. Proper dimensioning will also help manufacturers understand which features require tighter control during production.

Understand DFM

Designing for manufacturability (DFM) ensures parts are made with the least effort to no effort at all. While designing sheet metal components, consider bend sequencing, tooling restrictions, and material stretch.

When machining, through DFM, CNC capabilities have to be considered to preempt production complications. DFM feedback would be provided by DEK for optimizing your parts. They perform extraordinarily well and are easy.

Sheet Metal Specific Drawing Items

Drawing for the sheet metal should incorporate bend allowances, hole patterns, material type, thickness, surface finish, and assembly instructions. These sects guide the manufacturing team and prevent errors during bending, cutting, or forming.

Consider emphasizing features affecting milling, turning, or CNC operations so that machinists are better prepared to plan tool paths properly.

File Preparation and Manufacturer Collaboration

File preparation should consider multiple formats. PDF, STEP, and DXF to meet the assurances of compatibility with different machines and workflows. Confirming requirements from the manufacturer to avoid delays and ensuring that the relevant data gets to the production teams.

Properly set up files as a step to avoid any miscommunication issues that may arise. Especially concerning complex bends or tight tolerances.

Create a Drawing Checklist

Your full checklist should contain geometry, dimensions, tolerances, bend details, surface finish requirements, BOM, and revision history. This checklist should accurately record the drawings to be important for confirming the standards of sheet metal part design. Use of a checklist helps ensure that every important detail has been accounted for before manufacturing files are sent out.

Review Process

Before any drawing goes to production, a big review is done to ensure all errors and missing annotations are caught. This catches errors earlier and assures compliance with industry standards and sheet metal design guidelines.

Schlussfolgerung

Sheet metal part drawings are important for accurate, skilled shaping. They provide all dimensions, material specifications, and important ranges necessary for high-quality milling, turning, and CNC production.

DEK specializes in providing expert DFM feedback to help you optimise parts for smooth, precise manufacturing. With our guidance, you can ensure that your sheet metal components are fully manufacturable, minimise errors, and achieve the best production results possible. Kontakt jetzt.