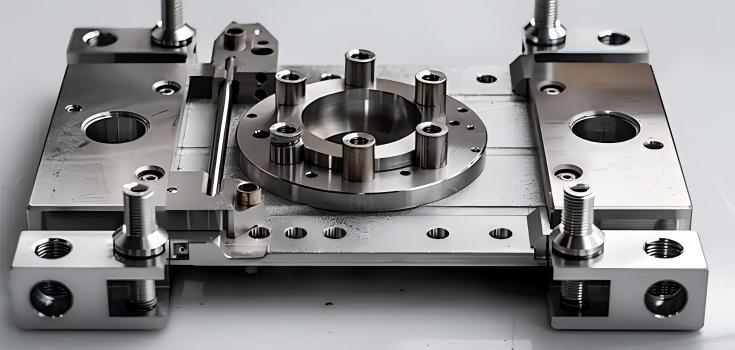

Jigs and fixtures demand tight tolerance control, parallelism, and long-term dimensional stability. The challenge lies in achieving consistent alignment, rigidity, and precise hole positioning for repeat setups.

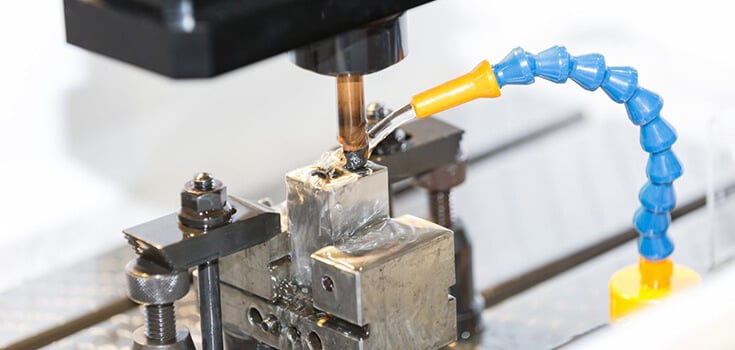

DEK applies 5-axis machining, wire EDM, and precision surface grinding to maintain flatness and perpendicularity. We also apply heat treatment and stress relief to minimize deformation and ensure long-term accuracy.

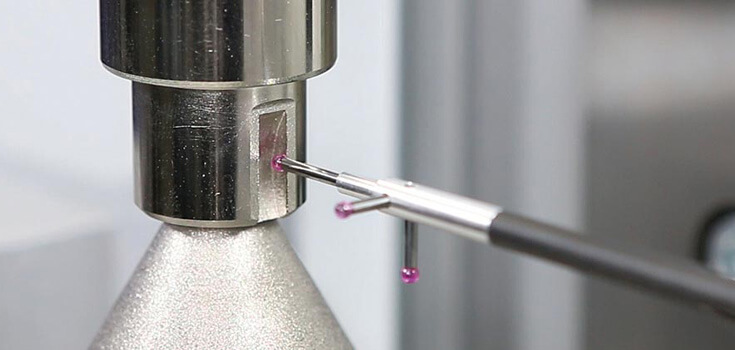

All components are verified using CMM, height gauges, and pin gauges to ensure consistent repeatability across setups and production batches.

Multi-angle locating faces and relief features are precisely machined in a single setup using 5-axis CNC to minimize compound errors and tolerance stack-up.

Wire EDM is applied on hardened blocks to achieve ±0.002mm positioning accuracy, especially for slot features and tight-fit holes with no thermal distortion.

Surface and cylindrical grinding ensures base plates, locating pins, and shims achieve <0.01mm flatness and surface roughness

We apply vacuum hardening and double stress-relieving cycles to stabilize tool steel components (e.g., D2, H13, SKD11), avoiding post-process deformation.

We support stainless steel inserts or Helicoils to ensure thread durability on aluminum jigs or soft fixtures. Manual torque test conducted on all threads.

Präzision, schnelle Durchlaufzeiten und keine Fehler - Maschinenbauingenieure verlassen sich auf DEK, wenn Fehler keine Option sind.

Send us your drawing—we’ll provide fast DFM feedback and a precise quote, no minimum order.