- Startseite

- Military and Defense

Precision Manufacturing of Military and Defense Components

DEK is a one-stop manufacturer of high-quality, complex, precision components for military and defense applications, with tight tolerances of ±0.005mm. Our expertise includes producing military components for ground defense vehicles, aircraft, spacecraft, electronics, and other military systems. Leveraging advanced CNC machining technology, we ensure reliable, competitively priced solutions with the highest quality and safety standards, compliant with DFAR regulations.

- 24/7 technische Unterstützung

- Schnelle Bearbeitung, kurze Vorlaufzeit, kein MOQ

- Instant Quotes and DFM Feedback

- Both Low and High Volumes Are Available

- ISO 9001:2015, AS 9100 certified and ITAR-qualified

Custom Military and Defense Parts Manufacturer

DEK is renowned for its superior quality and comprehensive services, providing reliable, precise, and flexible customized solutions for the defense industry based on demand.

As an ISO 9001 certified manufacturer, DEK specializes in high-precision military components, achieving tight tolerances of up to ±0.005mm. We strictly adhere to defense industry standards, excelling in machining titanium alloys, stainless steel, aluminum alloys, tungsten steel, and Inconel, ensuring that DEK’s components can withstand harsh conditions and maintain reliable performance.

Additionally, we offer surface treatments such as anodizing, electroplating, PVD coating, and plating. Our typical products include housings, end bells, starter rings, and other components. All quality inspections are conducted in-house, and we provide CMM inspection reports, FAI reports, material certificates, and RoHS certification.

CNC Defense Part

Defense Machined Part

Aluminum Part for Military

Turned Miltary Part

Spare Parts for Defense

Military Machied Part

Machined Parts for Defense

CNC Turning Fastener

Military and Defense Component Produktionskapazitäten

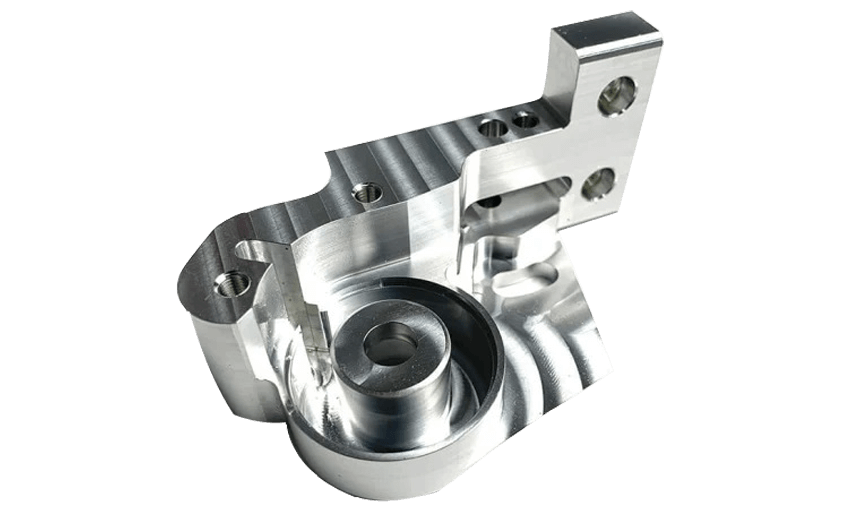

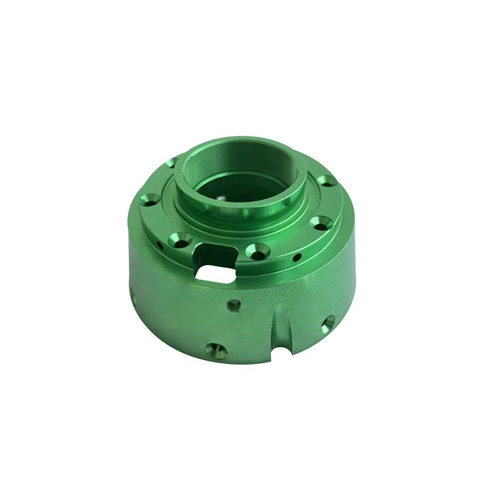

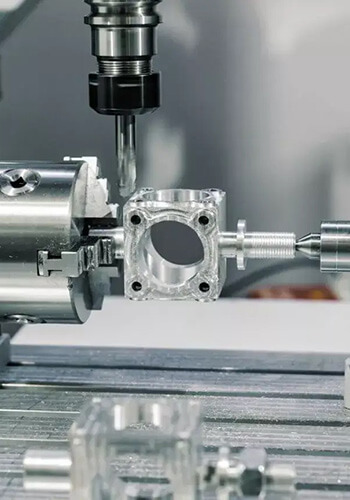

Präzisions-CNC-Bearbeitung

DEK possesses multi-axis CNC machining, precision turning, and complex component manufacturing capabilities, including milling, grinding, turning, boring, and reaming, meeting the stringent requirements of military and defense applications.

It is highly suitable for manufacturing aircraft structural components, military vehicle components, and naval and submarine parts. Whether you need a prototype or are seeking a reliable partner for small to medium batch production, DEK focuses on using production-grade materials and implementing strict in-house quality control to provide flexible and efficient solutions.

Herstellung von Blechen

DEK specializes in manufacturing high-quality custom sheet metal parts for military and defense applications, including military enclosures & casings, brackets & mounts, providing reliable structural support and protection for your critical components.

We offer a variety of sheet metal materials, including aluminum, stainless steel, and steel. From instant quotes to rapid production, you can obtain hundreds of high-quality sheet metal parts in just a few days. Additionally, we provide surface treatment options, including brushing, anodizing, and coating, to meet the high demands of your components.

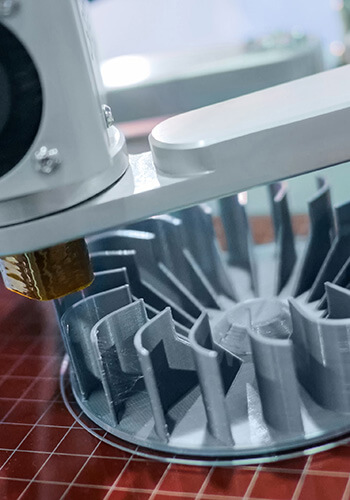

Industrieller 3D-Druck

DEK offers high-quality additive manufacturing services, enabling cost-effective rapid prototyping and on-demand production of wear-resistant, durable, complex geometric parts.

We provide a wide range of metals and plastics, including steel, PEEK, nylon, TPU, and PPS, for printing on-demand spare parts, UAV parts, custom jigs, and fixtures. Additionally, we offer surface treatments tailored to your project’s needs.

Aluminium-Strangpressen

Industrial aluminum profiles, with their high strength, lightweight, corrosion resistance, and exceptional design flexibility and modularity, have become indispensable structural materials in the military and defense industry.

DEK provides high-quality aluminum extrusion parts for the military and defense sector. Our classic cases include shelter frames, structural rails, heat sinks for electronics, and superstructure components. We can flexibly handle your projects, offering cost advantages in batch production.

Materialien

Materialien Optionen

Legierter Stahl

Alloy steel, known for its high strength, low cost, and adjustable toughness, is widely used in the military and defense industry, serving as a cornerstone material for heavy-duty equipment. Examples include aircraft landing gear actuators & joints, armored vehicle suspension components, and high-performance drivetrain gears.

Aluminium

Aluminum and its alloys are among the most widely used metals in the military and defense sectors, particularly aluminum 5083, aluminum 6061, and aluminum 7075. These alloys are highly suitable for manufacturing aircraft bulkheads and ribs, military electronics enclosures, satellite and spacecraft brackets, and other similar applications.

Titan

Titanium, with its high strength-to-weight ratio, excellent corrosion resistance, and high-temperature durability, is the preferred material for critical, high-performance components in modern advanced military equipment. It is ideal for manufacturing aircraft structural parts, jet engine fan blades & discs, submarine pressure hulls, and ballistic armor plating.

Inconel

Inconel offers exceptional overall performance under extreme high temperatures, high stress, and oxidative or corrosive environments. It is ideal for manufacturing turbine blades, turbine discs, nozzles, high-temperature fasteners, missile propulsion parts, and combustor liners.

Sofort & Genaue Zitate

Wir verwenden keine automatisierten Online-Kostenvoranschläge, weil sie sehr ungenau sind. Online-Kostenvoranschlagsplattformen stützen sich ausschließlich auf Berechnungen auf der Grundlage von Schnittmengen und festen Koeffizienten und berücksichtigen nicht die tatsächlichen Verarbeitungsnuancen, wie Materialverformung nach der Wärmebehandlung, enge Toleranzanforderungen, Schleifen nach der Wärmebehandlung usw. Folglich können automatische Preisberechnungen zu Ungenauigkeiten führen, die letztlich Ihre Kosten erhöhen.

Aber bei der DEK können Sie beruhigt sein!

Unsere Angebote sind sowohl kosteneffizient als auch präzise, da wir über ein Team professioneller Maschinenbauingenieure verfügen, die jede Zeichnung sorgfältig prüfen. Diese Ingenieure haben mehr als 10 Jahre Erfahrung und verfügen über fundierte Kenntnisse in den Bereichen Programmierung, Maschinenbetrieb, Nachbearbeitung, Materialeigenschaften und mehr. Wir versichern Ihnen, dass Sie innerhalb von 6 Stunden genaue Angebote erhalten.

Warum wählen Unsere Dienstleistungen

Die Produktion hochwertiger Teile aus einer Hand spart Ihnen Zeit und Geld.

Technische Fähigkeiten

Schnelle Vorlaufzeit

Oberflächenbehandlungen

Qualitätskontrolle

Präzisionsmontage

Packaging and Logistics

Unser Bestellvorgang

RFQ senden

Senden Sie eine Anfrage mit 2D/3D-Zeichnungen und detaillierten Anforderungen per E-Mail oder Online-Formular.

Rezension & Zitat

Unser Ingenieurteam wird jede Zeichnung sorgfältig prüfen und innerhalb von 6 Stunden ein genaues Angebot erstellen.

Bestellung bestätigen

Bestätigen Sie den Kostenvoranschlag, die Einzelheiten und den Lieferplan und unterzeichnen Sie dann den Vertrag.

Produktion

Produktionsprozess organisieren, Programmierung und Bearbeitung starten.

Qualitätskontrolle

Strenge Qualitätskontrolle während der Produktion und der Endkontrolle.

Verpackung und Versand

Verpacken Sie die Teile, bringen Sie Etiketten zur Identifizierung der Teile an, und beginnen Sie mit dem Versand.