- Startseite

- Automatisierung

Precision Parts Manufacturing for Automation Industry

DEK specializes in manufacturing precision mechanical parts for the automation industry, providing high-quality, durable, and consistently reliable components to global automation equipment manufacturers. DEK can rapidly produce complex parts with tight tolerances controlled within ±0.005 mm, using a variety of production-grade materials and surface treatment options. Your one-stop partner from prototyping to production.

- 24/7 technische Unterstützung

- Instant Quotes and DFM Feedback

- Both Low and High Volumes Are Available

- ISO 9001:2015 and ISO 14001:2015 certified.

- Schnelle Bearbeitung, kurze Vorlaufzeit, kein MOQ

Custom Automation Equipment Parts Manufacturer

DEK is renowned for its superior quality and comprehensive services, offering reliable, precise, and flexible customized solutions tailored to the specific needs of the automation industry.

As an ISO 9001 certified manufacturer, DEK specializes in high-precision components for automation equipment, achieving tight tolerances of up to ±0.005mm. We strictly adhere to automation industry standards, excelling in machining aluminum alloys, stainless steel, carbon steel, and engineering plastics, ensuring that every component processed by DEK is durable and wear-resistant.

In addition, we provide surface treatments such as anodizing, electroplating, black oxide, and passivation. Our typical applications include EOATs, jigs, gears, shafts, robotic arm joint housings, and structural frames. All quality inspections are conducted in-house, and we provide CMM inspection reports, FAI reports, material certificates, and RoHS certifications.

Automation CNC Part

Automation Equiment Part

Automation Equiment Steel Part

Automation Equipment Bracket

Automation Equipment Brackets

Base Plate Part

Robot Base Frame

Automation Machined Part

Automation Component Produktionskapazitäten

Präzisions-CNC-Bearbeitung

DEK possesses multi-axis CNC machining, precision turning, and complex component manufacturing capabilities, including milling, grinding, turning, boring, and reaming, meeting the stringent requirements of automation applications. It is ideal for manufacturing spline shafts, custom gripper jaws, fixture base plates, and bearing housings.

Whether you need a prototype or are seeking a reliable partner for small to medium batch production, DEK focuses on using production-grade materials and implementing strict in-house quality control to provide one-stop, flexible, and efficient solutions.

Herstellung von Blechen

DEK specializes in machining high-quality custom sheet metal parts for the marine industry, including radar mounting bracket, cable tray,ventilation louver, chain locker cover, and enclosure, providing reliable structural support and protection for your key components.

We offer a variety of sheet metal materials, including stainless steel, aluminum, and steel. From instant quotes to rapid production, you can receive hundreds of premium sheet metal parts in just days. Additionally, we provide surface treatment options such as brushing, anodizing, and coating to meet your parts' high demands.

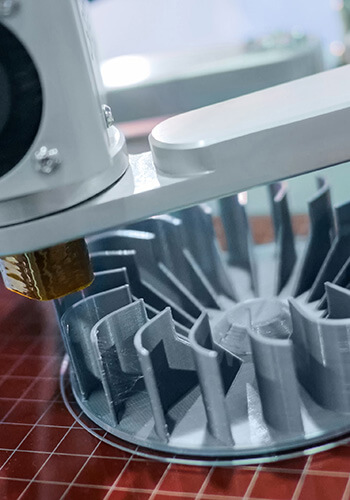

Industrieller 3D-Druck

DEK provides high-quality additive manufacturing services, enabling you to rapidly create prototypes at low cost and produce durable, wear-resistant parts with complex geometries on demand.

We offer a variety of metal and plastic materials, including ABS, nylon, TPU, and carbon fiber composites, for printing robotic grippers, custom enclosures, sensor mounts, jigs, and fixtures. Additionally, we provide surface finishing services tailored to your project's needs.

Aluminium-Strangpressen

Industrial aluminum profiles, with their high strength, lightweight, corrosion resistance, and exceptional design flexibility and modularity, have become indispensable structural materials in the automation industry.

DEK provides high-quality aluminum extrusion parts for the automation industry. Our classic cases include machine frames, robot pedestals, material racks, belt conveyor frames, and inspection equipment stands. We can flexibly handle your project, offering cost advantages in batch production.

Materialien

Materialien Optionen

Aluminium

Aluminum and its alloys are among the most widely used metals in the automation industry, particularly favored in robotics and structural frameworks. They are ideal for manufacturing robotic arms, structural components, machine frames, conveyor frames, guarding, linear motion guides, and motor housings.

Rostfreier Stahl

Stainless steel, with its excellent corrosion resistance and high strength, is ideal for the automation industry in environments with stringent requirements for cleanliness, durability, and chemical resistance. It is commonly used to manufacture wafer handling equipment, sensor and actuator housings, medical device components, fasteners, and fittings.

Kohlenstoffstahl

Carbon steel, with its high strength, low cost, and good machinability, is widely used in the automation industry, particularly for structural components that need to withstand heavy loads, such as gears, shafts, structural brackets, support arms, and heavy-duty machine bases.

Kupfer

Copper and its alloys (such as brass and bronze) are primarily used in the automation industry for their unparalleled electrical and thermal conductivity. They are ideal for manufacturing electrical connectors, terminals, pins, heat sinks, heat exchangers, bearings, and bushings.

Sofort & Genaue Zitate

Wir verwenden keine automatisierten Online-Kostenvoranschläge, weil sie sehr ungenau sind. Online-Kostenvoranschlagsplattformen stützen sich ausschließlich auf Berechnungen auf der Grundlage von Schnittmengen und festen Koeffizienten und berücksichtigen nicht die tatsächlichen Verarbeitungsnuancen, wie Materialverformung nach der Wärmebehandlung, enge Toleranzanforderungen, Schleifen nach der Wärmebehandlung usw. Folglich können automatische Preisberechnungen zu Ungenauigkeiten führen, die letztlich Ihre Kosten erhöhen.

Aber bei der DEK können Sie beruhigt sein!

Unsere Angebote sind sowohl kosteneffizient als auch präzise, da wir über ein Team professioneller Maschinenbauingenieure verfügen, die jede Zeichnung sorgfältig prüfen. Diese Ingenieure haben mehr als 10 Jahre Erfahrung und verfügen über fundierte Kenntnisse in den Bereichen Programmierung, Maschinenbetrieb, Nachbearbeitung, Materialeigenschaften und mehr. Wir versichern Ihnen, dass Sie innerhalb von 6 Stunden genaue Angebote erhalten.

Warum wählen Unsere Dienstleistungen

Die Produktion hochwertiger Teile aus einer Hand spart Ihnen Zeit und Geld.

Technische Fähigkeiten

Schnelle Vorlaufzeit

Oberflächenbehandlungen

Qualitätskontrolle

Präzisionsmontage

Packaging and Logistics

Unser Bestellvorgang

RFQ senden

Senden Sie eine Anfrage mit 2D/3D-Zeichnungen und detaillierten Anforderungen per E-Mail oder Online-Formular.

Rezension & Zitat

Unser Ingenieurteam wird jede Zeichnung sorgfältig prüfen und innerhalb von 6 Stunden ein genaues Angebot erstellen.

Bestellung bestätigen

Bestätigen Sie den Kostenvoranschlag, die Einzelheiten und den Lieferplan und unterzeichnen Sie dann den Vertrag.

Produktion

Produktionsprozess organisieren, Programmierung und Bearbeitung starten.

Qualitätskontrolle

Strenge Qualitätskontrolle während der Produktion und der Endkontrolle.

Verpackung und Versand

Verpacken Sie die Teile, bringen Sie Etiketten zur Identifizierung der Teile an, und beginnen Sie mit dem Versand.