- Startseite

- Ressourcen

- Wie man Teile für Industriemaschinen herstellt

Wie man Teile für Industriemaschinen herstellt

Manufacturing parts for industrial machinery is a crucial process that keeps factories, production lines, and automated systems running smoothly.

In this guide, you’ll learn about important information on how to manufacture parts for industrial machinery, such as the different types of parts used in industrial machines, the materials best suited for them, and the processes that can be used.

What is Industrial Machinery?

Industrial machinery includes all kinds of machines used in different industries to make, process, or produce products. These machines are designed for specific jobs to help businesses work more efficiently. Some common types of industrial machinery are:

Manufacturing Equipment: These machines help in making products. Examples include CNC machines, lathes, milling machines, presses, and industrial robots.

Material Handling Equipment: These machines move, store, and transport materials within a factory or workplace. Examples include conveyors, lift tables, and forklifts.

Packaging Machinery: These machines help in packing products quickly and properly. Some examples are filling machines, labeling machines, sealing machines, and wrapping machines.

Common Parts Made for Industrial Machines

The parts you need to make will depend on the type of machine and how it will be used. But in most cases, industrial machinery includes the following:

Moving Parts

These are pieces like shafts and bearings that help the machine move smoothly and transfer power efficiently.

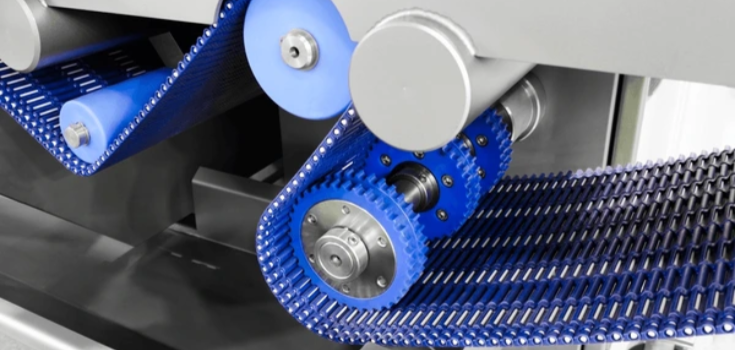

Conveyor Belts

Looping belts that carry materials or products through a factory, helping with movement, sorting, and processing.

Outer Casings

Protective covers that keep the machine safe from dust, dirt, and damage. They also provide structure and often have openings for easy maintenance.

Automation Parts

Components like actuators, controllers, and robotic parts that help machines work automatically. They make production faster and more precise.

Jigs and Fixtures

Special tools that hold or guide parts during manufacturing. They help keep everything in the right position for accurate and repeatable work.

Replacement Parts

These are new parts made to replace old or broken ones. They help keep machines running smoothly for a long time.

Materials Used to Make Industrial Machinery Parts

Industrial machinery parts are made from metals, plastics, and composite materials. Often, a mix of materials is used to get the best performance.

Metalle

Metals are strong, durable, and have great mechanical properties. Some common ones include:

Aluminum and Alloys: Lightweight yet strong, Aluminium is used in machine casings, conveyor systems, and parts where weight matters.

Stahl: Used for strong and durable parts like shafts, axles, and machine frames. It resists wear and corrosion.

Kunststoffe und Polymere

Kunststoffe are lightweight, insulating, and allow flexible designs. Some commonly used ones are:

Polycarbonate (PC) & Acrylic (PMMA): Transparent and impact-resistant, they are used for machine windows, protective covers, and display panels.

Polyethylene (PE) & Polypropylene (PP): Resistant to chemicals and strong, these are used for conveyor belts, rollers, and protective casings.

Elastomers (Rubber & Silicone): These flexible materials are great for seals, shock absorption, and vibration control.

Nylon (Polyamide): Strong and wear-resistant, nylon is used for gears, bearings, and bushings because of its low friction.

Verbundwerkstoffe

Composites combine different materials for special properties. Some examples are:

Fiberglas: Strong, lightweight, and corrosion-resistant, it’s used for machine enclosures and structural parts.

Kohlefaser: Extremely strong and stiff but lightweight, carbon fiber is used in high-performance machine components.

How are These Industrial Machined Parts Made?

Making machinery parts takes careful planning and the right tools. From design to quality checks, every step ensures the parts work well and last long.

Here’s a step-by-step look at how it’s done:

Designing the Parts

Just like building a house needs blueprints, making a machine part starts with a design. This plan shows the size, shape, and material. A good design makes production easier, reduces costs, and improves performance.

Choosing the Right Material

Picking the right material is like choosing ingredients for a recipe. The strength, durability, and cost all matter. Some materials resist rust, handle heat, or absorb impact better. Choosing the right one helps with manufacturing and keeps costs down.

Starting the Manufacturing Process

Before production starts, you gather materials, set up machines, and make a plan. The process includes cutting, shaping, machining, and heat treatment. Each step is checked to fix problems early and improve efficiency.

Checking for Quality

Quality control ensures every part meets the required standards. Inspections happen before, during, and after production. Tools measure size, strength, and surface quality. Keeping records helps improve future production and prevent mistakes.

Manufacturing Methods Used to Create Parts for Industrial Machinery

There are different ways to make parts for industrial machines. The method you choose depends on things like the type of part, the material, how precise it needs to be, how many you need, and the cost. Here are some common ways parts are made:

CNC-Bearbeitung

This method removes material from a solid block to shape the part. You can use tools like lathes, mills, drills, and grinders. CNC (Numerische Computersteuerung) machines help make parts more accurately and automatically

Herstellung von Blechen

This method shapes thin sheets of metal into parts using cutting, bending, and welding. It’s commonly used to make things like panels, brackets, and covers. Laser cutting is often used for precise shaping.

3D-Druck

This method builds parts layer by layer using plastic or metal. It’s great for creating detailed designs, prototypes, and small production runs.

Spritzgießen

This process injects melted plastic into a mold, where it cools and hardens into the final shape. It’s ideal for making large numbers of identical plastic parts.

Quality Control and Testing

Making sure each part meets high-quality standards is very important, especially for products that must be strong and safe. To do this, you need to run tests like visual checks, strength tests, and material analysis. Many industries also follow strict rules and international standards to ensure products are safe and reliable before they can be used.

Trends and Innovations in Industrial Parts Manufacturing

Manufacturing is always changing because of new technology. One major improvement is 3D printing, which helps you create complex parts with great accuracy while using less material.

Automation, like robots and artificial intelligence, also makes production faster and more efficient, helping to lower costs. These new technologies are changing how products are made, tested, and designed.

Environmental Responsibility

Today, companies focus on reducing waste and protecting the environment. Many manufacturers recycle materials, cut down on waste, and use renewable energy. Some even design products so that parts can be reused when they are no longer needed. These efforts not only help the environment but can also save money and improve efficiency.

Schlussfolgerung

Making parts for industrial machines takes careful planning, the right materials, and good manufacturing methods. When you choose the right process, you can create strong, reliable parts that help machines work better and last longer.

Unter DEK, we can make high-quality parts for your industrial machines. Whether you need CNC machining, sheet metal parts, or custom components, we are ready to help. Contact us today to get started!