- Startseite

- Ressourcen

- How to Make A Countersink Hole in Metal Workpieces?

How to Make A Countersink Hole in Metal Workpieces?

If you’re working with metal parts, you’ll often need to make clean, precise holes for screws or bolts. One of the most common things you’ll do is make a countersink hole. It helps the screw head sit flush with or below the surface.

In this blog, I’ll show you how to make a countersink hole in metal workpieces, step by step. Don’t worry, it’s easier than it sounds once you know what to do.

What are Countersink Holes?

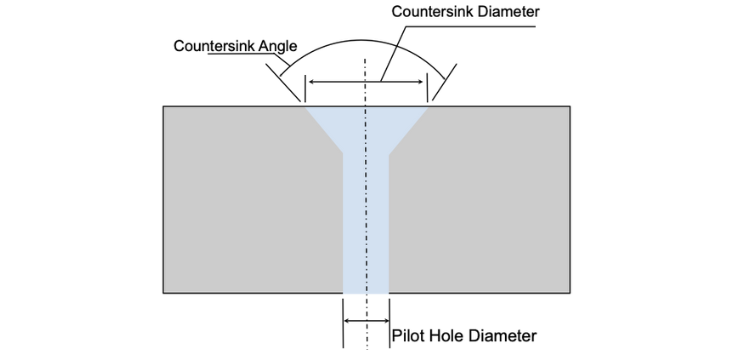

A countersink is a cone-shaped hole that you make in a surface. It lets the head of a screw or bolt sit flat or just below the surface. Why does that matter? It’s not just to make things look nice. It also makes the connection stronger and helps stop the screw head from sticking out and catching on things.

Different Types of Countersink Holes

The shape, angle, and size of the countersink hole all matter. When you get the hole right, the screw sits flat and spreads the pressure evenly. If you don’t, the material can bend or the screw might fail.

Flathead Countersink

You need to drill a cone-shaped hole that matches the angle of the screw head. This helps the screw sit flat with the material’s surface.

Oval-Head Countersink

These need a hole with a slightly rounded shape to fit the curved bottom of the screw head. This gives a nicer, more decorative look, so use it when appearance matters.

Round-Head Countersink

This type isn’t common, but if you need it, you should make a shallow, rounded hole that fits the shape of the screw head. The screw won’t sit fully flat like a flathead, as it will stick out a little. Use this when you a rounded screw look or when the screw doesn’t need to be flush.

How to Make A Countersink Hole in Metal Workpieces?

Here’s a step-by-step on how to make a countersink hole in metal:

Drill a Pilot Hole

Start with a pilot hole. Pick a drill bit the same size as the screw shaft or about 1.6mm smaller.

Clamp the metal so it doesn’t move. Mark the spot, install the bit, and drill straight down (at a 90-degree angle to the surface) until the hole is deep enough for the screw.

Check the Countersink Angle

Match the countersink angle to your screw. Use 90° for metric screws, 82° for standard screws.

This makes the screw sit flat and look neat.

Use the Correct Countersink Drill Bit

Use a caliper to measure the screw head, then pick a bit that matches its size.

Carbide works best for hard metals, high-speed steel is good for soft metals like aluminum, and cobalt is ideal for rostfreier Stahl.

Insert the Countersink Drill Bit Into the Drill Chuck

Depending on your drill, you might need to use a chuck key or just tighten it by hand. Make sure it’s snug but not overly tight, so it’s easy to remove later.

Adjust the Drill to the Right Depth

Start with 4mm or more, depending on your screw’s size.

If the depth is too shallow, the screw will stick out. If it’s too deep, there’ll be a gap around the screw.

Drill the Countersink Hole

Put the bit in the pilot hole and press gently. Drill until it’s deep enough for the screw head. Use cutting oil or WD-40 to cool and reduce friction. A drill press gives better depth control and cleaner holes.

Inspect the Countersink Hole

Test with a screw or bolt; it should sit flat. If not, adjust and redrill. Use a deburring tool to clean the edges for a smooth finish.

Different Materials of Countersink Drill Bit for Metal

As I’ve mentioned earlier, you have to use the right drill bit material depending on the metal you need to drill. Here are your choices:

Hochgeschwindigkeitsstahl (HSS)

HSS is a common option. These bits are made from strong materials like chromium, cobalt, and carbon steel. You can use HSS bits for metal because they stay hard even when they get very hot, up to 650°C. They also drill about three times faster than regular bits.

Hartmetall

These are made from a mix of carbon and tungsten. You can use them to drill into hard metals like copper, bronze, steel, aluminum, and cast iron. They can handle high speeds and heat, so they last a long time even when you’re working with tough materials.

Kobalt

Cobalt drill bits are made from high-speed steel mixed with cobalt, which makes them more heat-resistant. Cobalt bits are perfect when you’re drilling into very hard metals like stainless steel and cast iron.

Standard Countersink Angle in Different Uses

Here are the most common ones and how you can use them:

60° (For Deburring)

Use this angle to remove sharp edges or burrs from a metal part. It helps make the edges smooth after cutting or drilling.

75° (For Rivet Heads)

This angle works well with most types of rivets, like drive rivets, flush rivets, friction-lock, oscar rivets, self-piercing rivets, and solid rivets.

82° and 90° (For Countersunk Screws)

These angles are used when you’re working with countersunk screws. In the U.S., 82° is the standard. In other countries, 90° is more common. Make sure to use the angle that matches your screw type.

120° (For Countersinking Sheet Metal Rivets)

When you’re working with thin sheet metals and blind rivets, use a 120° angle. This angle is best for joining sheet metal parts.

Size Charts for Typical Countersink Dimensions

Below are charts that show the usual countersink sizes for 82°, 90°, and 100° angles.

Dimension Chart for 82° Countersink Angle in Inches

| Fastener Size (Thread) | Pilot Hole Diameter (Close Fit) | Pilot Hole Diameter (Normal Fit) | Pilot Hole Diameter (Loose Fit) | Countersink Diameter |

| #0 | 1/15 | 6/79 | 3/32 | 5/42 |

| #1 | 3/37 | 4/45 | 4/45 | 13/89 |

| #2 | 3/32 | 7/69 | 7/62 | 16/93 |

| #3 | 5/47 | 8/69 | 9/70 | 1/5 |

| #4 | 3/25 | 9/70 | 14/97 | 9/40 |

| #5 | 9/64 | 5/32 | 11/64 | 25/99 |

| #6 | 2/13 | 10/59 | 5/27 | 12/43 |

| #8 | 9/50 | 10/51 | 13/61 | 1/3 |

| #10 | 15/73 | 21/95 | 5/21 | 5/13 |

| #12 | 15/64 | 15/61 | 6/23 | 39/89 |

| 1/4 | 17/64 | 9/32 | 19/64 | 36/71 |

| 5/16 | 21/64 | 11/32 | 23/64 | 40/63 |

| 3/8 | 25/64 | 13/32 | 27/64 | 16/21 |

| 7/16 | 29/64 | 15/32 | 31/64 | 69/85 |

| 1/2 | 17/32 | 9/16 | 39/64 | 7/8 |

| 9/16 | 19/32 | 5/8 | 43/64 | 1 |

| 5/8 | 21/32 | 11/16 | 47/64 | 1 1/8 |

| 3/4 | 25/32 | 13/16 | 29/32 | 1 3/8 |

Dimension Chart for 90° Countersink Angle in Millimeters

| Fastener Size (Thread) | Pilot Hole Diameter (Close Fit H12) | Pilot Hole Diameter (Normal Fit H13) | Pilot Hole Diameter (Loose Fit H14) | Countersink Diameter |

| M3 | 3.2 | 3.4 | 3.6 | 6.94 |

| M3.5 | 3.7 | 3.9 | 4.2 | 8.96 |

| M4 | 4.3 | 4.5 | 4.8 | 9.18 |

| M5 | 5.3 | 5.5 | 5.8 | 11.47 |

| M6 | 6.4 | 6.6 | 7 | 13.71 |

| M8 | 8.4 | 9 | 10 | 18.25 |

| M10 | 10.5 | 11 | 12 | 22.73 |

| M12 | 13 | 13.5 | 14.5 | 27.21 |

| M16 | 17 | 17.5 | 18.5 | 33.99 |

| M20 | 21 | 22 | 24 | 40.71 |

Dimension Chart for 100° Countersink Angles in Inches

| Fastener Size (Thread) | Pilot Hole Diameter (Close Fit) | Pilot Hole Diameter (Normal Fit) | Pilot Hole Diameter (Loose Fit) | Countersink Diameter |

| #0 | / | 6/79 | 3/32 | 5/42 |

| #1 | 3/37 | 4/45 | 8/77 | 13/89 |

| #2 | 3/32 | 7/69 | 7/62 | 16/93 |

| #3 | 5/47 | 8/69 | 9/70 | 1/5 |

| #4 | 3/25 | 9/70 | 14/97 | 9/40 |

| #6 | 2/13 | 10/59 | 5/27 | 12/43 |

| #8 | 9/50 | 10/51 | 13/61 | 1/3 |

| #10 | 15/73 | 21/95 | 5/21 | 5/13 |

| 1/4 | 17/64 | 9/32 | 19/64 | 36/71 |

| 5/16 | 21/64 | 11/32 | 23/64 | 40/63 |

| 3/8 | 25/64 | 13/32 | 27/64 | 16/21 |

| 7/16 | 29/64 | 15/32 | 31/64 | 81/91 |

| 1/2 | 17/32 | 9/16 | 39/64 | 1 1/59 |

| 9/16 | 19/32 | 5/8 | 43/64 | 1 10/69 |

| 5/8 | 21/32 | 11/16 | 47/64 | 1 25/92 |

Pros and Cons of Countersink Holes

Now, let’s talk about the advantages and disadvantages of countersink holes.

Vorteile:

- Countersinking gives a smooth, flush finish, so the surface looks better.

- It hides screws, which makes the surface look cleaner and more functional.

- Countersinks spread the load more evenly, reducing stress on the surface.

- They lower the risk of damage during use.

Nachteile:

- Countersink holes require skill to make properly, not something just anyone can do.

- They don’t hold as much strength because the load is spread over a small area.

- While they look good, countersinks are more for appearance than structural strength, although they are still durable.

- It can be hard to get precise results, especially in tough jobs. If you hire a professional like DEK, you won’t need to worry about this.

- Hiring someone skilled to countersink can be expensive, raising overall costs.

- Countersink holes are not ideal for very hard materials because the surface might crack, and the tool could break if done wrong.

- They work best in compact designs where space is tight.

Common Mistakes to Avoid When Countersinking a Hole in Metal

In this section, we discuss some common mistakes people make and tips on how to avoid them.

Over-Drilling

Drilling too deep is a common mistake. If you drill too deep, the screw sits too low, which can mess up the fit and weaken the metal. A screw that doesn’t grip well can loosen over time. To avoid this, be careful not to drill past the required depth.

Incorrect Angle or Bit Size

The countersink angle needs to match the screw’s head. Most standard screws need an 82° angle, while metric screws need a 90° angle. Using the wrong angle can make the screw head stick out or fit poorly, affecting how well it holds.

Not Securing the Workpiece

If the metal isn’t clamped down, it can move while drilling. This can lead to inaccurate holes and increase the risk of injury. Always make sure the workpiece is securely held in place to prevent it from shifting during drilling.

Engineering Applications of Countersink Holes

Countersinks are used in many industries, and some of these are listed below.

Luft- und Raumfahrt: Countersink holes make screws and rivets flush, reducing drag and improving function. They help spread stress evenly to prevent damage.

Manufacturing & Assembly: Countersink holes hide screw heads for a cleaner look in products. They prevent interference in moving parts.

Automobilindustrie: Countersink screws keep car body panels flush, improving look and aerodynamics. They help secure interior parts while keeping a sleek design.

Elektronik: Countersink holes keep device surfaces smooth for better design and comfort. They prevent interference with circuit boards.

Konstruktion: Countersunk screws make decks safer and cleaner. They help drywall screws sit below the surface for a smooth finish.

Schlussfolgerung

Making a countersink hole in metal needs precision because it affects how the part looks. It’s a simple process, but you must be careful to avoid damaging the metal.

In this article, we talked about how to countersink a hole in metal. Are you looking for a reliable company to make countersink holes in your CNC metal parts? Kontakt zur DEK und fordern Sie ein kostenloses Angebot an.