- Startseite

- Ressourcen

- How to CNC Machine a Cylinder Head for High Performance Engines

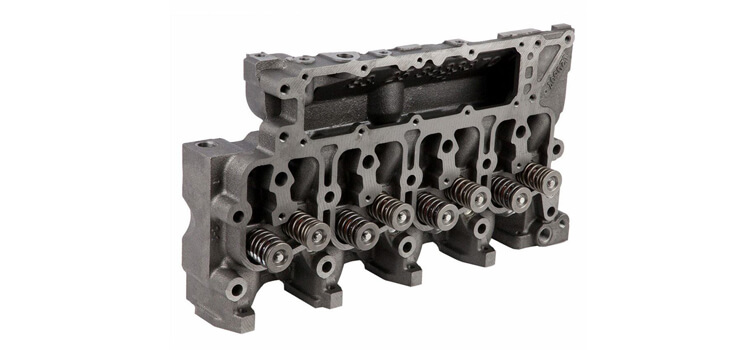

How to CNC Machine a Cylinder Head for High Performance Engines

Let's learn the intricate process of CNC machining cylinder heads to achieve optimal engine performance. By leveraging state-of-the-art technology and precision techniques, you, too, can unlock your engine's full potential.

Benefits of CNC Machining a Cylinder Head

Advantages Of CNC Cylinder Head Porting

CNC machining has revolutionized the cylinder head porting process, providing numerous advantages over traditional hand-porting techniques. One significant benefit is the remarkable consistency and precision that CNC machines offer.

With computer-aided programming controlling every aspect of the cutting process, each cylinder head can be manufactured to exact specifications, ensuring optimal engine performance.

Another advantage of CNC cylinder head porting is its ability to streamline production and reduce turnaround time. By automating some aspects of this labor-intensive task, I've seen first-hand how much more efficient my workflow becomes when using a CNC machine.

In addition to saving time, this level of automation also reduces manual errors commonly associated with hand-porting practices.

How CNC Machines Improve Accuracy And Precision

CNC Machines offer laser guidance, shaving capabilities, and precise specifications that traditional manufacturing processes can't match.

CNC programming allows for automation and ensures consistency from one job to the next. Along with Mastercam software and Centroid machines, CNC tools provide a level of sophistication that was once impossible in this industry.

The result is maximum performance achieved through porting and polishing techniques that are carefully programmed into the machine.

Thanks to their automated tasks and advanced capabilities, CNC machines have revolutionized cylinder head production - allowing us to achieve machined tolerances down to .0005 inches or better!

With these levels of precision now achievable, engine builders can design combustion chambers with optimal coolant flow patterns or mill areas around valves with high-stress points while ensuring we deliver an exact replica each time.

Strategies For Achieving Optimal Results

- Understand the engine's requirements and desired performance outcomes before starting the machining process.

- Select appropriate tools and fixtures based on the specifications of the engine model being worked on.

- Use precision CNC programming techniques that account for all machining tolerances and coolant flow aspects.

- Implement laser guidance systems to ensure accuracy and precision during machining operations.

- Utilize shaving techniques to remove any excess material from the cylinder head, ensuring that each component of the engine block is aligned correctly.

- Maintain a high level of automation throughout the machining process to improve efficiency and reduce error rates.

- Regularly check progress against desired results using comprehensive quality control and inspection methods, including measuring combustion chamber shapes, valve pocket alignment, and valve seat concentricity.

Types Of CNC Head Porting & Machining Centers

The Role Of CNC Machines In Engine Building

With incredible precision, these powerful tools automate and optimize the critical stages of machining, such as porting, Polieren, shaping, and valve machining.

In tandem with CNC machines, CAD software allows for real-time adjustments that ensure accuracy is maintained during every step of the process.

With state-of-the-art equipment like Centroid machine and Mastercam programming software, we can achieve machining tolerances within one-thousandth of an inch. This level of automation and sophistication guarantees consistency in performance from one cylinder head kit to another.

Additionally, many companies offer specialized services such as laser guidance shaving or coolant flow testing using advanced computer simulations.

The Level Of Automation And Precision Provided

CNC machines are simply the best for cylinder head machining for high-performance engines. And one of the main reasons is their level of automation and precision.

CNC machines have revolutionized engine building with unparalleled accuracy and consistency in manufacturing processes.

In addition, they allow for precise cutting path programming that ensures excellent dimensional tolerances with a minimum deviation margin.

For instance, modern Centroid machine tools come with advanced features like laser guidance, significantly improving tool positioning accuracy. This technology enhances shaving, resurfacing, and specifications tasks while ensuring full compliance with all design requirements without human error or intervention.

When coupled with software solutions such as Mastercam, this equipment can work at exceptional levels of sophistication and customization to meet even the most demanding performance needs.

The combination of automation and precision makes CNC cylinder head porting possible on previously impossible-to-machine contours, such as complex valve angles or irregular combustion chamber shapes, accurately.

So it's no wonder most high-end racing teams opt exclusively for CNC-Bearbeitungsdienstleistungen instead of traditional manual methods like milling machines or hand-porting techniques- there's just no comparison!

Selecting Appropriate Tools And Fixtures

Tool Material

Choosing the right tool material can improve machining efficiency and accuracy while reducing tool wear. High-speed steel, carbide, and diamond-coated tools are popular options.

Cutter Geometry

The cutter geometry should be selected based on the material being machined, the desired surface finish, and cutting speed.

Fixture Design

Proper fixture design ensures accurate and repeatable machining results. Factors such as part orientation, clamping force, and tool clearance must be carefully considered.

Coolant Syste

A well-designed coolant system can help to improve machining efficiency and extend tool life by reducing heat buildup during cutting operations.

Machine Control Software

Choosing the right machine control software is crucial for the efficient programming and setup of CNC machines. Programs like Mastercam offer advanced features such as 3D modeling, simulation, and optimization that can greatly enhance the machining process.

Best Practices For CNC Machining a Cylinder Head

Porting And Polishing Techniques

- Cylinder Head Flow Bench Testing: Before starting any porting or polishing work, it's important to test the airflow of the cylinder head using a flow bench. This will help determine which ports need more work than others.

- Port Matching: This technique involves matching the shape of the intake manifold to that of the cylinder head ports to maximize airflow into the engine.

- Removing Obstructions: The next step involves removing obstructions within the intake and exhaust ports, such as casting flash or raised bumps.

- Reshaping Ports: This technique involves reshaping the ports by removing material from certain areas and smoothing out rough spots to improve airflow.

- Smoothing Out Rough Spots: Once all obstructions have been removed and ports have been reshaped, it's important to smooth rough spots using abrasive materials.

- Blending Edges Together: Blending edges between different port surfaces help create a smooth transition for improved flow.

- Combustion Chamber Polishing: Polishing the combustion chamber can help reduce hot spots and improve overall performance.

Valve And Seat Machining Methods

- 3-Angle Valve Job: This involves cutting three angles on the valve seats to promote air flow and maximize efficiency. The angles are typically 45, 30, and 60 degrees.

- Cutters and Pilots: Cutters are used to create the desired shape on the seat, while pilots are used to keeping the cutter straight in the port.

- Bowl Cutting: This improves flow over the valve by creating a smoother transition from the valve seat into the cylinder.

- Radius Cutting: This type of machining involves creating a rounded edge on the top of each seat to reduce turbulence as air flows through.

- Seat Shaving: This technique reduces the height of a valve seat, which can increase airflow and power output.

Combustion Chamber Shaping Practices

- The shape of the combustion chamber should be optimized to promote efficient airflow and fuel combustion. This can be achieved through careful analysis of the engine's performance requirements and the use of computer modeling tools.

- Precision machining techniques like CNC milling should be used to shape the combustion chamber.

- The shape of the combustion chamber can significantly impact coolant flow through the engine block. Ensure that coolant flows efficiently by considering the port location and angle during design.

- Properly positioning spark plugs within the combustion chamber can improve ignition efficiency and reduce emissions. Consider using strategic placement techniques like offsetting or angling spark plug locations.

- After shaping the combustion chambers, it's essential to test thoroughly using specialized equipment like flow benches and dynamometers to ensure that all specifications and tolerances have been met.

Comprehensive Quality Control And Inspection Methods

- Before starting any machining process, it's important to inspect the cylinder head for any cracks, warping, or other defects that may affect performance.

- Using accurate measuring tools such as micrometers and dial gauges, I take precise measurements of critical areas such as valve seats, combustion chamber volume, and port dimensions.

- During the machining process, I carefully monitor the machine to ensure that all cuts are made accurately and within specified tolerances.

- Once the machining process is complete, I inspect the cylinder head to check for any imperfections or areas that require further attention.

- After completing all necessary modifications and machining processes, a pressure test can be conducted to ensure no leaks in the cooling system.

Performance Perspectives: CNC Machining A Cylinder Head For High-Performance Engines

Tips For Achieving Optimal Results

- Select appropriate cutting tools and fixtures to ensure precision and accuracy in your machining process.

- Constantly measuring dimensions throughout the machining process will help you adjust as needed, ensuring that your final product meets specifications.

- Working with skilled technicians familiar with CNC machining can give you insight into best practices and potential pitfalls to avoid.

- Proper coolant flow is essential for engine performance. Make sure to design cylinder head ports with optimal flow characteristics in mind.

- The shape of the combustion chamber can significantly impact engine performance. Consider factors like compression ratio, detonation resistance, and flame propagation when designing your chamber.

- Proper geometry is critical for achieving optimal engine performance. Ensure that your valve seats and guides are precisely aligned to maximize airflow.

- Careful attention should be paid to polishing cylinder head ports after machining them. Improper port finishing can result in uneven surfaces or improper airflow, affecting engine performance.

Ensuring Precision And Accuracy In Machining

Any small error can have significant effects on the engine's overall performance. Therefore, I use high-quality equipment, such as a Centroid machine or Mastercam software, to program and operate the CNC machines.

Monitoring coolant flow and tools regularly worn during the machining process is also essential. If either of these factors is off, it could result in an uneven finish or damage to the cylinder head.

Additionally, I always double-check my work using comprehensive quality control methods before moving on to the manufacturing process's next step.

Proper Cleaning And Deburring Techniques

- Use specialized cleaning solutions: Before machining the cylinder head, it's essential to clean it thoroughly using specialized cleaning solutions that remove any dirt, oil, or debris that could negatively impact the quality of the final product.

- Deburr edges and surfaces: After machining the cylinder head, you must deburr all edges and surfaces to prevent any damage during transportation or installation. You can use specialized tools like rotary files or abrasive stones to remove any burrs, sharp edges, or rough spots.

- Remove coolant residues: Coolants lubricate and cool down the cutting tool and workpiece during machining. Once machining is complete, you must remove any coolant residues that could cause corrosion or affect the engine's performance.

- Inspect for cleanliness: After cleaning and deburring your cylinder head, take time to inspect it thoroughly for cleanliness. Any remaining debris can affect the accuracy and precision of your CNC machine tool's measurements.

- Store in a clean environment: Finally, store your finished cylinder head in a clean location, away from any potential contaminants like dust or moisture, until it's ready for installation in an engine.

Key Takeaways For CNC Machining High-Performance Cylinder Heads

The level of automation and precision provided by CNC machines significantly improves accuracy in porting and polishing techniques, valve and seat machining methods, and combustion chamber shaping practices.

Comprehensive quality control and inspection methods guarantee optimal results while ensuring proper cleaning and deburring techniques.

Another key takeaway is the importance of selecting appropriate tools and fixtures for CNC head porting. This involves understanding the role of CNC machines in engine building and their sophistication in programming equipment to perform specific tasks.

By selecting the right tools based on specifications such as coolant flow, cylinder block, engine displacement, crankshaft design, piston design, and spark plug location, you can achieve more accurate results that meet your clients' needs.

Consider consulting with experts like DEK who can provide valuable insights regarding CNC machining a Cylinder Head. Contact us now!