- Startseite

- Ressourcen

- Kundenspezifische Uhrenteile: Materialien, Verfahren und Endbearbeitung

Custom Watch Parts: Materials, Process, and Finishing

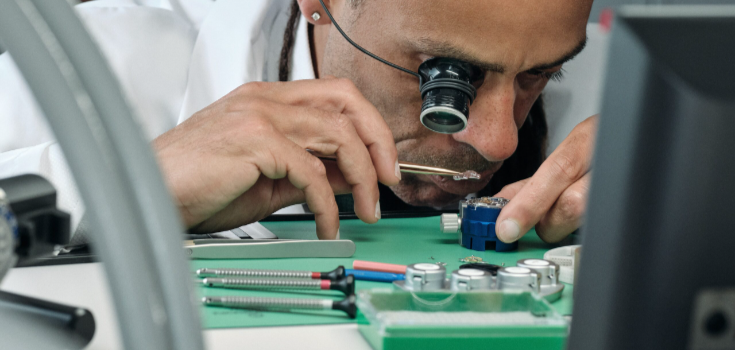

Watches may be small, but they’re made up of many tiny parts that must fit and work perfectly. If even one part is not made right, the whole watch might not work. CNC machining is one of the best ways to make custom watch parts.

In this guide, you will learn everything about CNC machining custom watch parts, such as the materials, machining processes, and finishing methods you can use.

Designing Custom Watch Parts for CNC Machining

To start, you’ll need a clear design for each part. You can use CAD software to create a digital model of each part, which shows how everything will look and fit before cutting any material. Then, CAM software turns your design into instructions that guide the CNC machines.

It’s a good idea to make a prototype first so you can check the fit, functionality, and appearance. This helps you spot problems early, as well as save time and cost in the long run.

Material Selection for CNC Watch Parts

The common materials you’ll use when CNC machining custom watch parts are listed below:

Rostfreier Stahl

It’s tough, long-lasting, and resists rust. You can also polish it for a premium look. However, you have to take note that it is heavier than aluminum and titanium, so it takes more effort to machine than aluminum.

Titan

Titan is harder and more expensive to machine than aluminum, and the raw material also costs more. The good thing is that it is strong, lightweight, rust-resistant, and safe for sensitive skin.

It is great for high-end, luxury, and diving watches where strength and corrosion resistance matter.

Aluminium

Aluminum is softer than other metals and scratches more easily, but it is lightweight, easy to machine, and looks good, especially after Eloxieren.

It is best for sports watches, special edition models, budget-friendly models, or designs with custom colors.

CNC Milling for Custom Watch Parts

CNC-Fräsen is an important process when making watch parts because it is known for the following:

Präzision und Genauigkeit

This process is great for making watch cases, dials, crowns, and movement parts. These components need exact measurements to fit and function properly. CNC milling provides reliable, high-precision results every time. This reduces errors and ensures smooth assembly.

Material Vielseitigkeit

You can machine different materials with CNC milling. The material you select depends on the watch’s performance needs, such as strength, weight, or resistance to corrosion.

Oberflächenveredelung

CNC milling creates clean, smooth finishes. This quality is essential for visible parts of the watch, such as cases and bracelets. It ensures every detail looks sharp and meets high standards for appearance.

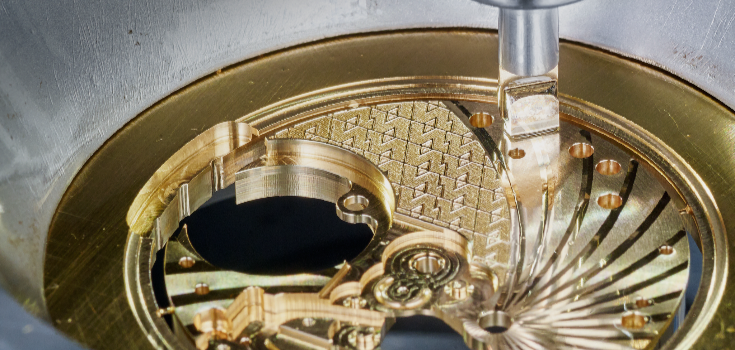

CNC Machining for Complex Watch Components

CNC machining can help you make complex watch parts with very fine details that traditional tools cannot handle. It lets you create detailed shapes like hollow cases, fine engravings, and 3D designs with ease.

Multi-Axis Milling

Using multi-axis CNC machines like 3, 4, or 5-axis, you can machine parts from different angles without moving the workpiece. This is ideal for creating curved cases, custom engravings, and detailed features all in one smooth process.

Consistency and Efficiency

CNC machining reduces the chance of mistakes and keeps part sizes consistent. It also speeds up production while maintaining the quality, whether you are making a few prototypes or a large batch of parts.

Precision Tolerances in CNC Machining Watch Parts

When making watch parts, you need to work with very small tolerances. Even the tiniest error can affect how the watch runs or fits together.

Micro-Tolerance Control for Watch Parts Machining

Many parts, like gears, pivots, and escapements, need tolerances as tight as 0.01 mm or less. Tight tolerances make sure parts fit together properly, which keeps timekeeping accurate and improves durability.

Parts like cases, crowns, and brackets also need exact measurements to protect the movement and maintain water resistance.

CNC Machining Accuracy in Watchmaking

To achieve this level of accuracy, you’ll need high-quality CNC machines and precision cutting tools. Diamond-coated tools, fine tips, and high-speed spindles help cut tiny details cleanly without errors.

CNC machines are also great for making consistent parts. Once you set the program, it will repeat the same cut over and over, so every part matches the exact design, whether it is for a few pieces or a large batch.

Surface Finishing for Custom Watch Parts

Different finishes give each part its own style and feel, and these are the most common methods you’ll use:

Polieren

Polishing gives the surface a bright, shiny, mirror-like finish. It is mostly used on watch cases and bracelets to give them a clean and elegant look. You use polishing wheels and abrasive compounds to smooth out imperfections and create a reflective surface. It is perfect for stainless steel, gold, and other luxury materials.

Bürsten

Brushing gives the surface a soft, matte look with fine, straight lines. You use an abrasive brush to create this even texture. It is a modern, simple finish that hides scratches well, which is why it is a good choice for everyday watches.

Sandstrahlen

Sandblasting adds a smooth, textured surface by blasting the part with fine sand or glass beads. It creates a clean, non-reflective finish that reduces glare and hides fingerprints. This finish works well for back cases, bezels, and decorative parts.

PVD-Beschichtung

PVD (Physical Vapor Deposition) adds a thin, hard coating to the surface inside a vacuum chamber. It improves scratch resistance and lets you add colors like black, gold, or gunmetal. You’ll often use PVD on watch cases, bezels, and bracelets.

Case Study: CNC Machining the Apple Watch

Here’s a look at how CNC machining is used to make the Apple Watch, from material selection to final assembly.

Choosing the Right Material

Apple uses different materials for its watch models, like aluminum, stainless steel, ceramic, and titanium. Aluminum is popular for being light and tough, while stainless steel gives a heavier, premium feel. Ceramic and titanium are used on some models for their unique looks and extra durability.

CNC Machining Process

It starts with a detailed CAD model for parts like the case, buttons, and covers. CNC machines then cut, drill, and shape the parts using processes like milling and turning, so each piece meets the exact size and shape needed.

Qualitätskontrolle

Every part is checked carefully before assembly. Tolerances, strength, and appearance are inspected to catch any problems as soon as possible. This helps keep quality high and ensures the finished watch works well and lasts long.

Assembly

After machining and finishing, all parts are put together. This includes fitting the case, sensors, screen, and electronics. The assembly process needs high accuracy so every part fits perfectly and the watch performs as it should.

Innovations in CNC Technology

Apple keeps improving its CNC processes to make production faster, reduce material waste, and improve precision. New machining technology also helps speed up the launch of new models and supports creative, advanced product designs.

Schlussfolgerung

Making custom watch parts requires the right materials, careful design, and accurate CNC machining. Every part needs to be precise to keep the watch running smoothly and looking good.

If you need high-quality, custom-made watch parts, DEK is always ready to help. We offer fast, reliable CNC machining services for small, complex components with tight tolerances and smooth finishes. Contact us today, and get a free quote for your next project.