- Startseite

- Ressourcen

- CNC Machining vs Die Casting: Which is Better for Your Prototype?

CNC Machining vs Die Casting: Which is Better for Your Prototype?

When you’re working on a new prototype, you need to choose the best way to make it. One common question is which one you should use between CNC machining vs die casting.

In this blog, you’ll learn what each process is, how they’re different, and which one is better for your prototype.

Was ist CNC-Bearbeitung?

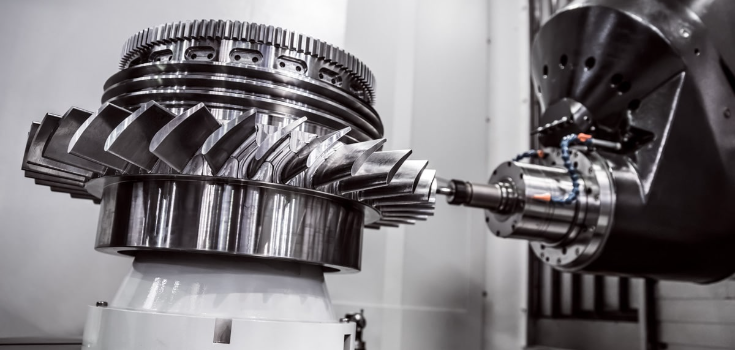

CNC machining is a way to shape components by removing material. You use a computer to control a machine like a mill or lathe. The machine follows a program and slowly cuts away the metal until it reaches the final shape you want.

There are different types of machining you can use, such as turning, milling, drilling, or sawing. It can also include more advanced methods like Laserschneiden, waterjet cutting, or Drahterodieren.

Vorteile:

- You get high accuracy and repeatable results.

- It’s great for both small and large production runs.

- You can make complex shapes and designs.

- CNC machines work fast and save you time.

- You don’t need as much manual labor.

- The final parts usually need little finishing.

Nachteile:

- Machines and tools can be expensive.

- You need skilled workers to run and program them.

- Setup can take time, especially for custom jobs.

- Not ideal for soft or flexible materials.

- Some shapes might waste a lot of materials.

Was ist Druckguss?

Die casting is a way to make metal parts using reusable molds called dies. You melt a non-ferrous metal like aluminum and inject it into the mold under high pressure. This process is fast and good for making parts that are strong, smooth, and the same every time. It’s better than CNC machining when you need to make a lot of parts quickly.

It works well for large production runs, but it does have limits. You can only make parts that fit within the machine’s size range, and the type of metal you use can affect how detailed the part can be.

Vorteile:

- You can make parts with very thin walls.

- Once set up, the process needs little human supervision.

- Dies can be reused many times, saving costs over time.

- It’s great for making parts with fine details or logos.

Nachteile:

- The dies are expensive to make.

- Not suitable for small production runs due to high setup costs.

- The process works only with certain metals, like aluminum, zinc, or magnesium.

- Parts may have tiny air pockets which can weaken them.

Difference Between Die Casting and CNC Machining

Druckguss melts metal and injects it into a steel mold or die, where it cools and hardens into the shape of the part. CNC machining uses a robot to cut and shape the metal into the desired part.

Here’s a summary table of the difference between die casting vs CNC machining:

| Merkmal | Druckgießen | CNC-Bearbeitung |

| Dünne Wände | Can make walls as thin as 0.08 inches. | Can create thin parts, but not for long shapes. |

| Thick Walls | Thick walls take longer to cool and fill. | Good for thick parts with unusual shapes. |

| Fäden | Can mold threads directly or add them later. | Threads are cut or added after production. |

| Hollow Parts | Great for making complex hollow shapes. | More difficult and time-consuming to make. |

| Part Assembly | Can combine designs into one part, reducing assembly needs. | Often requires connecting several small parts. |

| Curved Surfaces | Can create complex curves in one step. | Needs multiple setups and can be costly. |

| Sharp Corners | Limited by the mold design. | Can achieve sharp corners with small tools. |

| Unterschneidet | Hard to make; requires complex molds. | Easier to produce. |

| Abmessungstoleranzen | Moderate accuracy, improves with additional machining. | Very precise and tight tolerances. |

| Oberfläche | Smooth finish, usually needs little extra work. | Finish varies and often requires extra work. |

Choosing Between CNC Machining vs Die Casting

Below are the main factors that you need to think of before choosing what process to use for your prototype, CNC vs casting.

Prototyping

Die casting isn’t ideal for prototyping because molds are expensive and need to be remade every time the design changes, which increases costs and delays.

CNC-Bearbeitung is better for prototypes. It’s easier to change the design by simply updating the model and program, without needing to remake molds.

Teil-Geometrie

If your part has complex shapes or internal cavities, die casting is a good choice since it simplifies the design. CNC machining works better for thick, solid parts that require high precision.

Materialien

Die casting uses less material and allows for easy reuse of excess. But you only have a few material options for die casting. However, CNC machining works with a wider range of materials, so you have more options.

Production Speed

Die casting can be quick once the mold is ready, so it is good for high-volume production. But designing and machining the mold takes time.

CNC machining is faster for smaller quantities of parts since there’s no need to wait for mold creation. You just need a CAD model, a CAM program, and a CNC machine to start making parts.

Repeatability and Precision

Die casting makes highly repeatable parts once the mold and process are set up, but precision can vary based on the material. CNC machining offers more precision, with tighter tolerances. It’s an accurate process, especially for small parts.

Quantity and Demand

If you need only a few parts early in the process, CNC machining makes sense. It’s also better if your demand fluctuates, as you can produce parts on demand.

Die casting is better for large quantities. If you expect high demand and need thousands of parts, casting is the more efficient choice.

Tolerances and Design Capabilities

CNC machining is perfect when you need parts with fine details and tight tolerances. You can get tolerances as high as ±0.0005 inches (±0.0127 mm). CNC machines can handle deep holes, sharp edges, and detailed curves that casting can’t easily do.

Die casting isn’t as precise as CNC machining; tolerances usually range from ±0.002 to ±0.005 inches (±0.05 to ±0.13 mm). It’s best for large volumes of the same part with good design consistency.

Surface Finish and Aesthetics

CNC machining gives you smooth surfaces with little or no extra work. It’s great for fine details and aesthetics. Die casting offers decent surface quality, but may need sanding or painting. It is best for making many parts with a uniform finish.

Durability and Strength

With CNC machining, you can use tough materials like steel and titanium to handle heavy use. You can design CNC parts to be even tougher by using special machining techniques.

Die casting also makes strong parts, but you’re limited to materials like aluminum and zinc. Keep walls even and add features like ribs and gussets to avoid weak spots.

Customization and Flexibility

CNC machines use software, so if you want to change your design, it’s quick and simple. You don’t need to spend a lot of extra money, especially if you’re still early in the process. It works well for prototypes or any project where you need something unique.

On the other hand, die casting, as mentioned earlier, is best when you need to make a lot of the same part. It’s not as easy to change the design once you’ve started. These dies are expensive and hard to change, so if you want to change the design, you will need a whole new mold.

Kosteneffizienz

With CNC machining, the cost for each part stays about the same, whether you make a few or a few hundred. But the setup can cost a lot at the start. For small batches, that setup cost can be a big part of the total price. If you make more parts, the cost per part goes down, so it’s more affordable for medium-sized jobs.

Making the mold for die casting costs a lot at first. But once you have it, you can use it to make many parts quickly and cheaply. The more parts you make, the less each one costs.

Precision Custom Parts by DEK: CNC Machining & Die Casting Experts

Unter DEK, you get high-quality CNC machining and die casting services. We use advanced technology and have the experience to make sure your parts are made with great quality and speed.

Reach out to DEK. Our team will help you pick the best manufacturing process for your project.

Schlussfolgerung

If you’re making a prototype, CNC machining is your best option. It’s faster, easier to adjust, and lets you test different designs without needing costly molds. You can make changes quickly and use a wide range of materials. Die casting works better later, when you’re ready to produce large quantities.