- Startseite

- Ressourcen

- CNC Machining Tolerances: All You Need to Know

CNC Machining Tolerances: Alles, was Sie wissen müssen

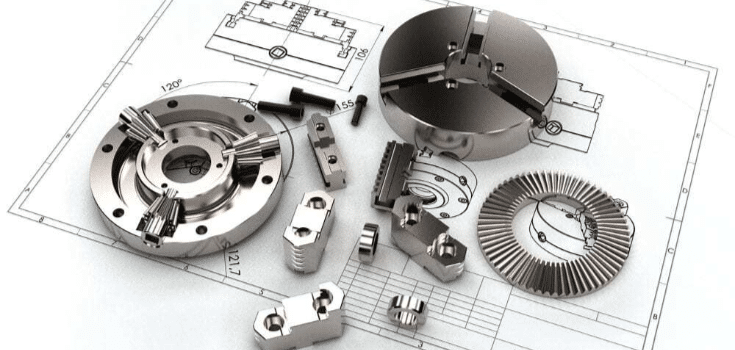

The CNC machining process is opted as it manufactures components using different tools and techniques. The components are manufactured with high precision, detailed cuts, and accuracy. However, the finish and accuracy attained are due to the CNC machining tight tolerances offered.

The significance of these tolerances cannot be denied, and if you are eager to learn more about them, go through the guide below.

What are CNC Machining Tolerances?

CNC machining tolerance is the limit of dimension variation that is allowed in the CNC machined parts.

The tolerance of a machined part offers insight into the accuracy of the machining process. In order to attain high precision and accuracy, the machining tolerance needs to be minimal.

Why are Machining Tolerances Important?

The significance of CNC machining tolerance is substantial. It ensures the perfection of the component and also plays a vital role in its performance.

Improve Parts Fit and Function

CNC tolerance ensures that the part, when assembled, interacts with the other one perfectly, leaving no loopholes.

The CNC machining tolerance is an indication of compatibility between the components. Hence, if there is a major deviation from the permissible dimensions, the functionality of the component can be affected.

Rule a Margin of Error

Every manufacturing process has a minor degree of variation; hence, the machining tolerance always accounts for such deviation.

The margins are determined within which the function of the part can be achieved. Hence, such a margin is kept in line while machining the component. It ensures that the chances of part failure are reduced.

Control Machining Cost

Die machining cost increases when the tolerance is tightened; the components with tight tolerances need some secondary finishing processes, which add to the cost. By having the tolerance defined, the increase in the cost can be prevented.

Ensure the Product’s Final Look

High precision enhances the final look of the part. When the two parts are assembled together without any gaps the perfectly finished assembly is achieved.

Different Terms for Measuring CNC Tolerances

When measuring CNC tolerances, there are some terms that are important to understand, and these are as follows:

Basic Size

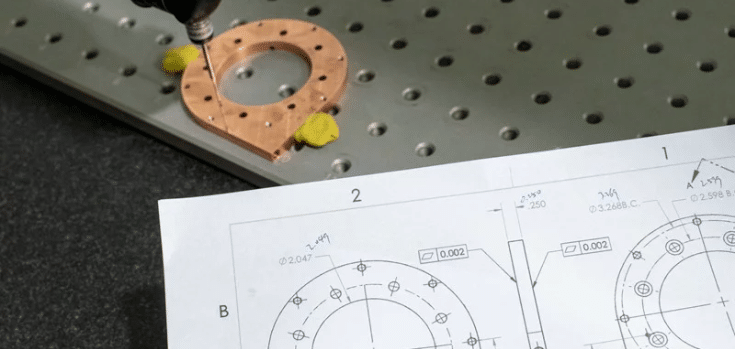

The basic size is given in the drawing of the component, and it accounts for the deviation allowed during machining.

Actual Size

The actual size of a component represents the dimension of the component after the machining process has taken place. The actual size is the final size achieved for the machined part.

Limits

The limits of a part are the maximum and minimum dimensions that are allowed in machining. The lower limit is the acceptable minimum deviation, and the upper limit represents the maximum allowed dimension.

Deviation

Deviation represents permissible size maximum variance compared to the basic size. There are two allowed limits: lower and upper deviation. The two of these deviations can be derived by subtracting the upper and lower limits from the basic sizes.

Datum

Datum means the imaginary plane or line which is used as a point of reference for the measurement tools.

Maximum Material and Least Material Requirements

Maximum material conduction takes place when the workpiece has the maximum material overall; in such case, there is a bonus tolerance to work with. Meanwhile, the least material condition is when there is the least amount of material in a workplace.

Decimal Places

CNC machining is a highly precise process that consists of very small amounts of tolerance. Therefore, to measure the tolerances, decimals places are used. The higher decimal places relate to tighter tolerance.

Calculating Tolerance

In order to calculate the machining tolerance, you will need the upper and lower limits.

You can take an example of a screw which has a diameter of 10 mm. The upper and lower limit acceptable in this regard would be 12mm and 8 mm, respectively. When you subtract the two limits, you get the level of tolerance, which will be 4mm in this case.

Common Types of Tolerances in CNC Machining

Es gibt verschiedene Arten von CNC machining tolerances that manufacturers consider when manufacturing components. Some of these are as follows:

Standard-Toleranzen

Standard tolerances are the type of tolerances that you may opt for when manufacturing commonly used products. Machinists mostly use a tolerance of +/- 0.1mm in CNC milling in cases where the customers determine the preferred level of tolerance.

Bilateral Tolerances

Bilateral tolerance is the variation of the tolerance from the given dimension, which can be either negative or positive. Hence, it allows for a very minor variation in the form of an increase or decrease in the component.

Geometric Dimensioning and Tolerancing

Geometric dimensioning and tolerancing detail the standard machining tolerance. It is a more complex system than the typical one and uses the control frames to indicate the specific types of dimensional tolerances of the components.

It allows keeping the actual measurements of the components within the given boundaries. It also indicates the geometrical properties of the component like its position, flatness, and concentricity.

Unilateral Tolerances

Unilateral tolerances offer to have variation in a single direction either positive or negative. For instance, a tolerance that is given as +0.00/-0.05 allows for the component to be smaller by 0.05 and not bigger.

Limit Tolerances

Limit tolerance indicates the range of values in which the machined part offers acceptability of the measurement to lie in a given range.

Common CNC Machining Tolerance Standards

The table below shows the common CNC machining tolerance standards.

| CNC Machining Process | Toleranz |

| 5- axis CNC Milling | ± 0.13 mm |

| CNC-Gravur | ± 0.13 mm |

| Gasket Cutting Router | ± 0.762 mm |

| Steel Rule Die Cutting | ± 0.381 mm |

| Router | ± 0.13 mm |

| 3-Achsen-CNC-Fräsen | ± 0.13 mm |

| Screw Machining | ± 0.13 mm |

| CNC-Drehmaschine | ± 0.13 mm |

| Surface Finish Standard | 125RA |

What Factors Affect Machining Tolerance?

There are some factors that affect the machining tolerance in a workpiece, and these are given below:

Materialien

The material’s characteristics impact the tolerances in the CNC machining, like the hardness, abrasiveness, and how stable it is when subjected to heat.

If the material is highly abrasive, it leads to tool wear and difficulty maintaining dimensional accuracy, which turns out to be challenging.

Softer materials, on the other hand, are prone to shifting when worked with under the tools and require added care to attain precision.

Many non-metals lead to deformity when subjected to high temperatures, and hence, it impacts the tolerance.

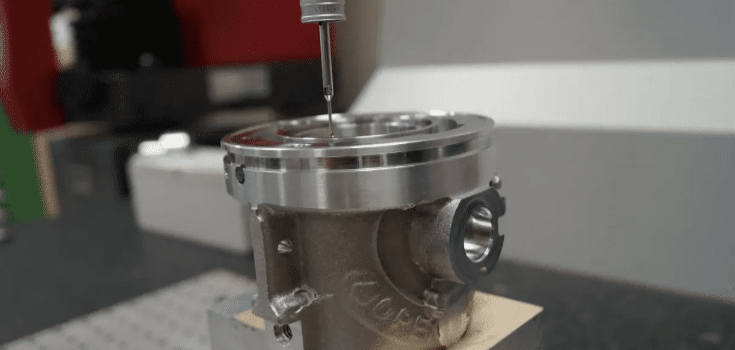

Bearbeitungsverfahren

The type of machining process chosen plays a vital role in tolerance maintenance. Every process has different capabilities and also limitations.

Also, CNC machines that have multiple axes work in different ways, and to achieve the required tolerance, it is important to choose the right process.

Oberflächenbehandlungen

The finishing processes impact the tolerances in the machining. Some components pass through the different surface treatments, which impact the dimensions of the machined parts.

Hence, it is important to choose a surface finish that keeps the tolerance of the components within the given range.

CNC Cutting Tools

There are different types of cutting tools that are used by machinists, which also impact the tolerance.

High-quality tools that have appropriate coatings and sharpness ensure high precision, whereas the ones that do not may lead to slight deviations.

Haushalt

The choice of tools for machining and materials is based on your budget. Tight tolerance needs special tools, more time, and specialized labor, which leads to increased costs. However, if you invest in the right tools, you can achieve the right tolerance.

Machinist Skills

The skills of a machinist also play a vital role in determining the tolerance of the component. The machinist is responsible for setting the machining parameters and choosing the right tool to attain the required tolerance.

Practical Tips for CNC Machining Tolerances

The practical types for obtaining the right CNC machining tolerances are as follows:

- The materials chosen should be capable of machining while keeping the tolerance range attained. For instance, some materials like steel and copper contract and expand due to temperature changes, and hence, the tolerances need adjustments.

- The application of the product also determines the tolerance level. Some parts are not meant to be assembled and are less precise, so they don't need tight tolerance.

- Opt for tools that offer high performance and quick cuts so that there are no deflections in the tools and that the tolerance is tight.

Schlussfolgerung

The significance of tolerance in machined components is highly crucial and impacts the success of the projects.

If you need to have your components designed with relevant tolerance, you can contact DEK. We at DEK have experienced machinists taking care of the precision tolerance of the components.

FAQs

What are the most common machining tolerances?

The most common tolerance for machined components falls in the range of +/- 0.005.

Which tolerance is the most difficult to machine?

The tolerance, which is less than +/- 0.001, is the ones which are most difficult to machine.

Which industries need precision CNC tolerances?

Industries that are sensitive to precise tolerances include medicine, automobiles, electronics, and aerospace.