- Startseite

- Ressourcen

- CNC-Bearbeitung in der Landwirtschaft: Vorteile, Verfahren und Anwendungen

CNC Machining in Agriculture: Benefits, Processes, and Applications

Agriculture has improved with modern machines that make farm work faster, easier, and more efficient. These machines need strong and reliable parts to work well in tough conditions.

That’s where CNC machining in agriculture helps. It makes precise, high-quality parts for different agricultural equipment. Here, you’ll know its benefits, processes, materials, and applications in the agricultural industry.

Benefits of CNC Machining in the Agricultural Industry

Here are six important advantages of using CNC Machining in agriculture:

Highly Customizable

You can make parts that fit exactly to your needs, whether it’s a custom plow, special shaft, or unique irrigation part.

Precise and Accurate Parts

CNC-Maschinen make parts with exact sizes and shapes. This makes sure everything fits properly and your equipment works with extra adjustments.

Efficient Production

CNC machines work quickly and can run all day and night. This helps you get your parts on time, especially during busy seasons.

Anpassungsfähigkeit

CNC machines can cut and shape a wide range of materials, including metal and plastic, that’s why it is easier to create different kinds of farming tools and machine parts.

Flexible Rapid Prototyping

CNC machining helps you create sample parts and test new tools quickly, so it is easier to improve faster.

Faster Repairs

If a machine part breaks, CNC machining can quickly make a replacement. This keeps your farm running without long delays.

Different Machining Processes for Manufacturing Agricultural Parts

Below are four common processes you can use:

CNC-Fräsen

With this machining process, you remove material with spinning cutters to make detailed shapes like curves, slots, and holes for parts like gearboxes.

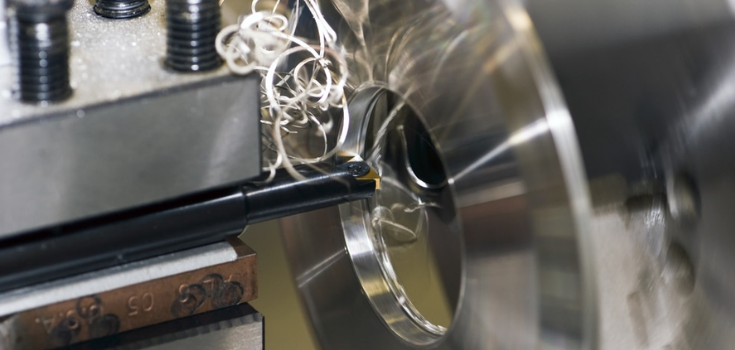

CNC-Drehen

You spin the material while a cutting tool shapes it. This is great for making round parts like shafts and hubs.

CNC-Bohren

In this process, you drill holes that are exactly the right size and well spaced to make it easier to assemble components like irrigation systems.

EDM (Electrical Discharge Machining)

EDM is perfect for cutting hard-to-machine materials with detailed parts like nozzles and gears.

Applications of CNC Machined Agricultural Components

These are some examples of agricultural parts you can make using CNC machining:

Pulleys: Help your machines move belts smoothly.

Tubing: Carries water, air, or chemicals in your equipment.

Ritzel: Work with chains to move different machine parts.

Spray System Parts: Control how water or chemicals spread over your crops.

Air Collectors: Gather and move air in farm machines.

Chain Guides: Keep chains in place while your machine runs.

Gears: Help your machine turn, lift, or move parts.

Bushings: Reduce friction between moving parts and extend equipment life.

HDPE Flooring: Strong, easy-to-clean floors for animal pens or farm buildings.

Useful Tips for Optimizing CNC Machining for Agricultural Parts

Use the Right Materials

For harsh farm conditions, choose sturdy, reasonably priced materials that are resistant to rust and damage, like steel and aluminum.

Use Quality Tools and Workholding

Invest in reliable work-holding systems and long-lasting cutting tools to improve machining accuracy, remove vibration, and produce stronger parts.

Consider Surface Finishes

Skip the expensive surface finishes on basic farm elements to save time and money. Since most farm components don’t require them.

Use Tight Tolerances Only When Necessary

Use strict tolerances only for those parts needing high accuracy, such as bearings or pistons, to reduce machining expenses.

Avoid Deep Cavities

To minimize machining time, cost, and the possibility of errors, avoid deep and narrow gaps in part designs.

Choosing the Right CNC Machine Shop for Your Machined Agricultural Components

There are many factors that you need to consider when machining parts for the agricultural industry, and some of these are the following:

Material Knowledge

Choose a shop that knows which materials work best for farming, offering tough, reasonably priced options for heavy outdoor use.

Modern Equipment

Choose a company with advanced CNC machines that deliver clean, precise, and high-quality parts for all your farming needs.

Schneller Turnaround

Find a shop with a good record of quick delivery, especially during busy seasons.

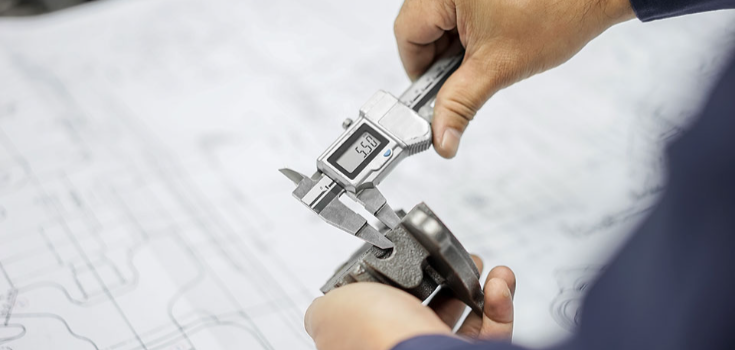

Quality Checks

Make sure the shop has strict quality controls to ensure every part is of high farming safety and performance standards.

Agriculture Experience

Partner with a CNC company that understands farm challenges and can make sturdy parts built for heavy farm work.

DEK’s Precision Custom Agricultural Machine Parts

DEK offers CNC machining services made to fit your farming needs. We follow strict quality checks and provide cost-effective solutions. As an expert in high-precision machining, DEK delivers reliable and high-quality parts you can trust. Kontakt anytime and get a free quote.

Schlussfolgerung

CNC machining helps keep your farm equipment running with strong, custom, and accurate parts. It saves time, lowers costs, and ensures your machine stays in good shape. With the right CNC partner, you’ll get parts made fast and built to handle different farm conditions.

FAQs

Which types of CNC machines are commonly used in the agricultural industry?

CNC milling machines and turning lathes are the most commonly used to make accurate parts for tractors, machines, and farm equipment.

How is the machining efficiency of CNC machining in the agricultural industry?

CNC machining is fast and accurate. It uses automation and high-speed tools to make farm parts quickly, saving time and money.

What are the parts commonly manufactured for agriculture using CNC machining?

Some commonly used parts include irrigation fittings, harvesting tools, sprockets, gears, PTO shafts, and components for tractors and hydraulic systems.