Automotive CNC Machining Service

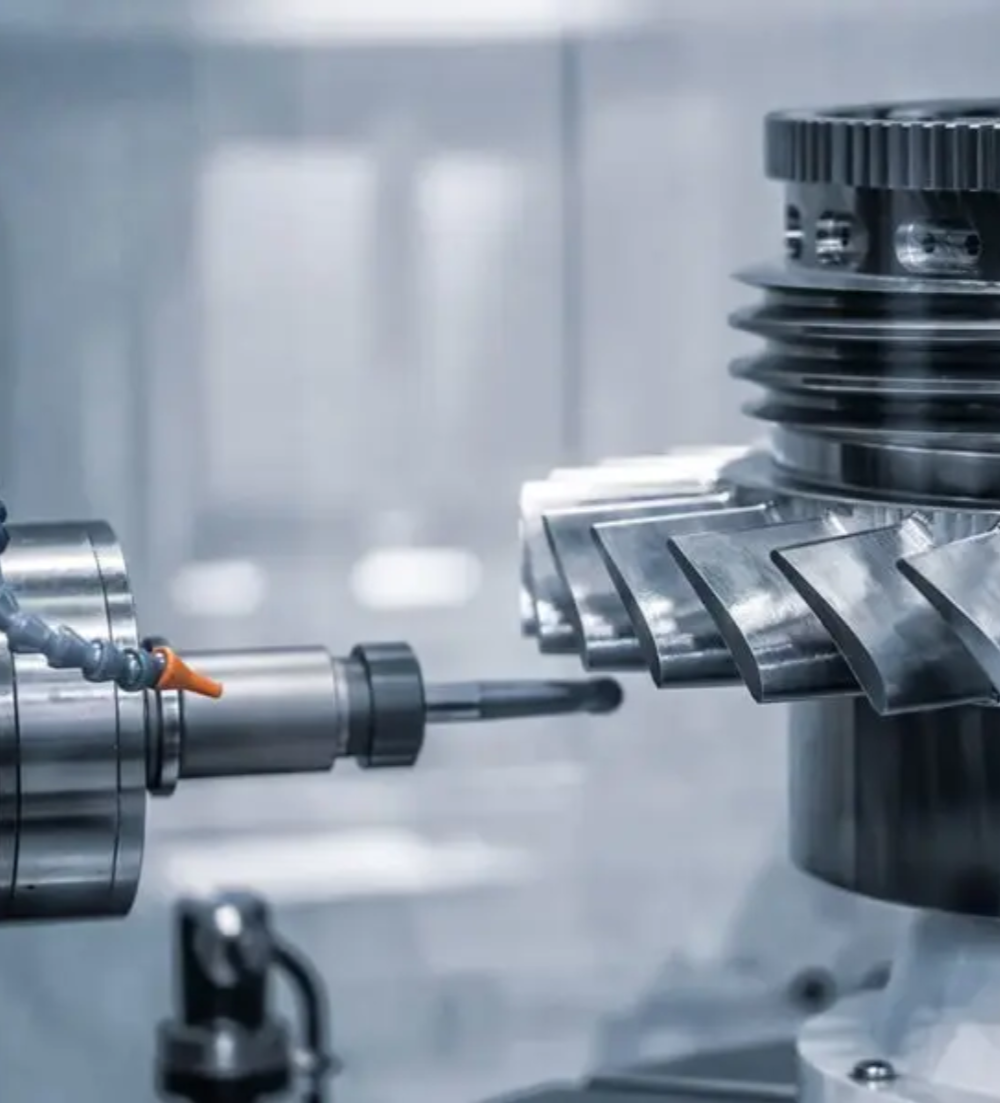

Automotive CNC machining provides highly precise, accurate, and consistent automotive parts. The manufacturing process offers unique techniques from 3-axis to 4-axis and 5-axis CNC machining.

At DEK, we specialise in delivering tight-tolerance and excellent-quality automotive components that meet the varying requirements of clients. We are capable of handling complex geometry designs, thanks to our advanced 5-axis machining process and team of experts. Whether you wish to create custom parts or a high volume production, we are here to serve you.

Einführung

Automotive CNC Machining Service – Highly Precise, Accurate, Reliable

At DEK, we understand how critical and delicate automotive components can be, and we deliver our service to meet the best precision, quality, finishing, and efficiency that you desire.

Our sophisticated CNC machining facilities, team of professional and readily available materials, allow us to deliver reliable and stress-free services. No matter how complex your design is, we are capable of handling it, thanks to our advanced 4 and 5-axis machining tools. What’s more, we are certified under ISO 9001:2015, which guarantees you that we are reputable and regulatory compliant.

Our service is relatively cheaper than industry standard, and we have no minimum order quantity, thus making us your ideal partner when cost effectiveness is a big deal.

- Schnelle Abwicklungszeit

- Relatively affordable service

- Tight tolerance of +/-0.005mm

- Availability of various materials

- Highly secured global delivery

- Specialised custom finishes

CNC-Bearbeitung für die Automobilindustrie Materialien

Metalle

Kunststoffe

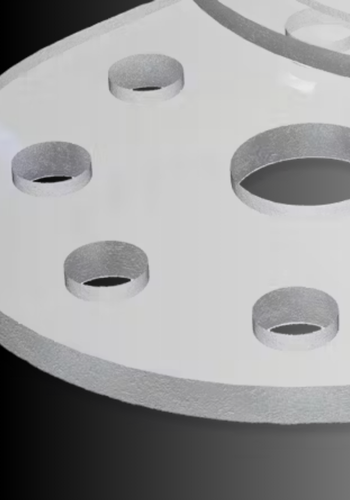

Aluminium

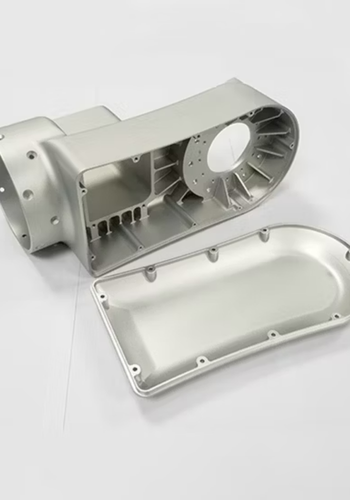

Aluminum is a lightweight, corrosion-resistant metal with excellent thermal and electrical conductivity. It is easy to machine and offers a good strength-to-weight ratio, making it ideal for high-performance and fuel-efficient applications in automotive engineering.

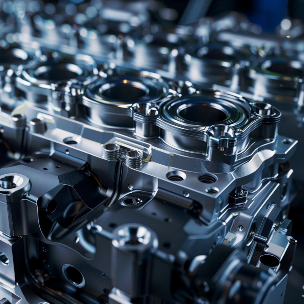

At DEK, we use aluminum to produce precise and durable automotive components like transmission housing, brackets, wheel hubs, etc, that meet demanding design specifications. Our advanced automotive CNC machining service ensures tight tolerances, smooth finishes, and consistent quality. Whether you need small or high-volume production, we deliver reliable aluminum parts.

Legierung

Aluminum 2014, 2017A, 2024, 5052, 5083

Messing

Brass is a copper-zinc alloy known for its excellent machinability, corrosion resistance, and good thermal conductivity. It also has a distinctive gold-like appearance, making it suitable for both functional and decorative automotive uses.

DEK machines brass with care and precision, using advanced CNC processes that maintain high quality and dimensional accuracy. Our team focuses on delivering clean finishes and long-lasting performance. You can count on us for dependable brass components that reflect DEK’s commitment to excellence.

Legierung

Messing 260, C360, Cz121

Kupfer

Copper is a highly conductive metal with excellent corrosion resistance and thermal transfer properties. It is malleable, durable, and often used in automotive systems requiring efficient heat or electricity flow.

At DEK, we machine copper components like current terminals and connectors, heat exchangers, battery busbars, etc, to the highest standards. Our automotive CNC machining service ensures precise shaping and tight tolerances, essential for copper’s sensitive performance roles. We focus on delivering clean, polished finishes and stable results, offering components with high quality and accuracy.

Legierung

Kupfer C101, C110

Magnesium

Magnesium is one of the lightest structural metals, offering a high strength-to-weight ratio and good heat dissipation. It is commonly used where weight reduction is critical without compromising performance and durability.

We at DEK specialize in machining magnesium parts with extreme care, using precise CNC methods to avoid distortion or defects. Our experts ensure that the final parts meet the strictest quality standards with excellent finishes. DEK helps you achieve lighter, more efficient automotive solutions without sacrificing reliability or mechanical performance.

Legierung

AZ31B, AZ61B und AZ91D

Rostfreier Stahl

Stainless steel is a strong, corrosion-resistant metal that maintains its properties under extreme temperatures and harsh environments. It offers high strength, durability, and a clean surface finish, ideal for automotive settings.

DEK uses stainless steel to produce components that meet rigorous quality expectations. Our CNC machining delivers consistent results, tight tolerances, and excellent surface finishes. With a strong focus on durability and aesthetics, we make sure your stainless steel parts hold up to both functional and visual standards in demanding industries.

Legierung

Stainless Steel 15-5, 17-4 PH, 2205 Duplex, 301, 303

Titan

Titanium is a high-strength, lightweight metal with exceptional corrosion resistance and heat tolerance. It has a high strength-to-weight ratio, making it valuable in high-performance and critical automotive applications.

At DEK, we handle titanium with precision, using specialized automotive CNC machining service methods that preserve its strength and integrity. We ensure smooth, clean finishes and excellent dimensional accuracy. Our team is experienced in machining titanium to exact specifications, helping you achieve high-performance parts. These parts include exhaust valves, connecting rods, wheel lug bolts, and nuts.

Legierung

Titanium Grade 1, 2, 5.

Zink

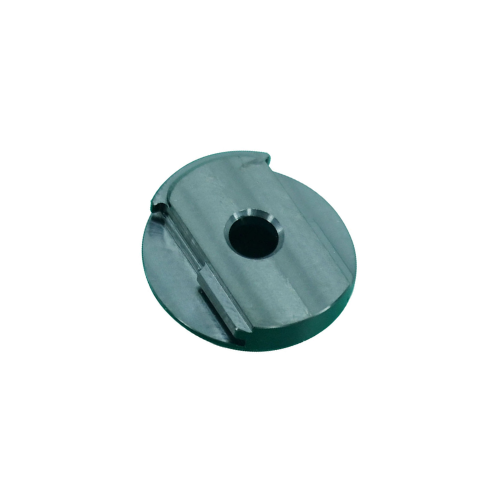

Zinc is a corrosion-resistant metal that is easy to machine and often used in die casting. It offers good strength and dimensional stability, especially in small and complex parts with tight tolerances.

DEK utilizes zinc for projects requiring intricate machining and excellent surface quality. Our CNC processes ensure parts with accurate geometries, repeatable results, and professional finishes. We take pride in delivering zinc components that match your expectations for strength, aesthetics, and consistency.

Legierung

Zamak 3

ABS

ABS is a tough, impact-resistant plastic with excellent dimensional stability and surface finish. It is lightweight, easy to machine, and has good resistance to physical stress, making it useful in various automotive applications.

At DEK, we machine ABS parts with high precision to meet your exact design needs. Our automotive CNC machining service provides smooth, uniform surfaces, clean cuts, and consistent accuracy across every batch. We maintain strict quality control throughout production to ensure your ABS components perform reliably. DEK focuses on delivering long-lasting, well-finished ABS parts like console housing, dashboard panels, air vent grilles, etc that meet both mechanical and aesthetic demands.

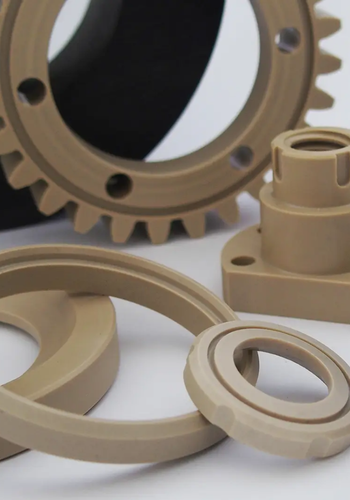

PA

PA is a strong, wear-resistant thermoplastic with good chemical and abrasion resistance. It is lightweight, has excellent toughness, and is commonly used where mechanical durability is needed in automotive applications.

You can count on DEK to produce PA parts with top precision and quality. Our CNC machining capabilities allow us to handle PA’s flexibility and wear resistance with ease. We carefully manage each step to avoid warping and achieve fine tolerances. With a focus on clean finishes and consistent results, DEK ensures your PA components meet the highest industrial standards.

Klassen

Nylon 6, Nylon 6 (30% Glass Filled), Nylon 6/6 (30% Glass Filled), Nylon 6 Flame Retardant.

PC

PC is a transparent, tough plastic with high impact resistance and dimensional stability. It resists heat and UV exposure, making it ideal for automotive environments where strength and optical clarity are important.

At DEK, we focus on automotive CNC machining services to shape PC into reliable, high-quality parts like cluster covers, headlight lenses, display panels, etc. Our processes ensure accurate dimensions, crack-free surfaces, and superior finishes. We monitor every stage closely to maintain clarity and toughness. Whether you require short runs or larger volumes, we consistently deliver PC components that reflect our focus on detail, performance, and durability in all applications.

PEEK

PEEK is a high-performance plastic with outstanding mechanical and thermal resistance. It performs well in extreme temperatures and chemical environments, offering excellent wear resistance and dimensional stability in automotive settings.

DEK’s CNC machining expertise ensures we meet the high demands of PEEK with care and precision. We maintain consistent temperature control and tooling conditions to avoid defects and guarantee top-tier surface finishes. Our process produces PEEK parts that retain structural integrity under stress. With DEK, you get durable, high-spec plastic components that reflect our commitment to excellence and industry-leading precision.

PET

PET is a strong, lightweight plastic with good dimensional stability and resistance to moisture and chemicals. It offers excellent machinability and is widely used where clarity and strength are both important.

When using PET, DEK delivers reliable, consistent results through controlled automotive CNC machining service operations. We focus on producing dimensionally accurate parts like sensor housing, fuse box components, etc, with smooth finishes and stable performance. Our experience with PET helps us avoid chipping or stress, ensuring every component meets your application’s needs. With DEK’s commitment to precision and finishing, you always receive PET parts you can depend on.

POM

POM is a low-friction, high-strength thermoplastic known for its excellent dimensional stability and wear resistance. It is easy to machine and suitable for tight-tolerance automotive components requiring smooth movement and durability.

At DEK, we machine POM to exact specifications, ensuring that each part meets your strict requirements. Our CNC capabilities allow us to maintain consistent quality and accurate dimensions, even for complex shapes. We pay close attention to surface finish and structural integrity. With DEK, your POM parts benefit from efficient machining and expert craftsmanship.

Klassen

Delrin 150, Delrin AF (13% PTFE-gefüllt), Delrin (30% glasgefüllt)

PP

PP is a lightweight, chemically resistant plastic with good impact strength and fatigue resistance. It is cost-effective, easy to machine, and suitable for various automotive applications involving stress and heat exposure.

DEK’s CNC machining processes allow us to shape PP into high-performance parts with smooth finishes and accurate dimensions. We carefully control the cutting environment to reduce stress and warping. Our team ensures consistent quality, whether you need prototypes or full production runs. With DEK’s attention to detail and high precision, you receive PP parts that meet industry standards.

Klassen

PP Homopolymer, PP+GF(30%)

Sofort & Genaue Zitate

Wir verwenden keine automatisierten Online-Kostenvoranschläge, weil sie sehr ungenau sind. Online-Kostenvoranschlagsplattformen stützen sich ausschließlich auf Berechnungen auf der Grundlage von Schnittmengen und festen Koeffizienten und berücksichtigen nicht die tatsächlichen Verarbeitungsnuancen, wie Materialverformung nach der Wärmebehandlung, enge Toleranzanforderungen, Schleifen nach der Wärmebehandlung usw. Folglich können automatische Preisberechnungen zu Ungenauigkeiten führen, die letztlich Ihre Kosten erhöhen.

Aber bei der DEK können Sie beruhigt sein!

Unsere Angebote sind sowohl kosteneffizient als auch präzise, da wir über ein Team professioneller Maschinenbauingenieure verfügen, die jede Zeichnung sorgfältig prüfen. Diese Ingenieure haben mehr als 10 Jahre Erfahrung und verfügen über fundierte Kenntnisse in den Bereichen Programmierung, Maschinenbetrieb, Nachbearbeitung, Materialeigenschaften und mehr. Wir versichern Ihnen, dass Sie innerhalb von 6 Stunden genaue Angebote erhalten.

Unsere Vorteile

2300+ Ingenieure Liebe Arbeit mit uns

Extreme Precision

In the automotive industry, every micron matters. That’s why DEK delivers CNC machined parts with extreme precision and tolerances as tight as ±0.005mm. We use advanced multi-axis machining centres and real-time inspection systems to ensure that each part fits and functions flawlessly in your vehicle.

Komplexe Geometrien

No matter how intricate your part design is, DEK can handle it. Our advanced 5-axis and multi-axis CNC machines make it possible to machine parts with challenging shapes, undercuts, and angles that traditional methods can't manage. We can bring even the most complex automotive components to life.

Kosteneffizienz

We understand the need to balance quality and budget, especially in automotive machining. DEK offers highly competitive pricing without compromising precision or durability. Our optimized CNC processes reduce material waste and machining time, helping you save money.

Zertifizierte Qualität

When you work with DEK, you’re choosing a partner that follows strict international quality standards. We are ISO 9001:2015 certified, and our processes include thorough inspections, documentation, and traceability. This ensures every CNC-machined part meets your exact specifications and industry standards.

Material Vielseitigkeit

You can choose from a wide variety of metals and plastics. We machine materials that suit your performance and budget needs. This versatility means your designs are never limited by material constraints. We’ll help you select the right material to match your requirements.

Schneller Turnaround

Time matters in automotive manufacturing, and we take that seriously. DEK delivers fast turnaround times for both prototyping and full production orders. Thanks to our advanced equipment and streamlined workflow, we complete projects efficiently without sacrificing quality.

Unser Bestellvorgang

RFQ senden

Senden Sie eine Anfrage mit 2D/3D-Zeichnungen und detaillierten Anforderungen per E-Mail oder Online-Formular.

Rezension & Zitat

Unser Ingenieurteam wird jede Zeichnung sorgfältig prüfen und innerhalb von 6 Stunden ein genaues Angebot erstellen.

Bestellung bestätigen

Bestätigen Sie den Kostenvoranschlag, die Einzelheiten und den Lieferplan und unterzeichnen Sie dann den Vertrag.

Produktion

Produktionsprozess organisieren, Programmierung und Bearbeitung starten.

Qualitätskontrolle

Strenge Qualitätskontrolle während der Produktion und der Endkontrolle.

Verpackung und Versand

Verpacken Sie die Teile, bringen Sie Etiketten zur Identifizierung der Teile an, und beginnen Sie mit dem Versand.

RFQ 222 senden

Rezension & Zitat

Bestellung bestätigen

Produktion

QC

Lieferung

FAQ

CNC-Bearbeitung für die Automobilindustrie FAQs zum Kauf

Genaues Angebot einholen Für Ihre nächsten Projekte

Ganz gleich, ob Ihr Projekt kompliziert oder einfach ist, ob es sich um Metall oder Kunststoff handelt, Sie erhalten innerhalb von 6 Stunden ein genaues Angebot.

Heute ein Angebot einholenAbout CNC-Bearbeitung für die Automobilindustrie

What is Automotive CNC Machining?

Automotive CNC machining is a manufacturing process that uses computer-controlled machines to produce precise, complex, and high-performance parts for vehicles. Whether it’s a one-off prototype or a full production run, this process ensures that every piece is crafted with accuracy and consistency. CNC machines operate using digital instructions generated from your CAD models, eliminating human error and increasing production speed.

This method supports a wide range of materials, including aluminum, steel, and high-performance plastics. Because of its precision, repeatability, and ability to handle complex geometries, CNC machining is widely used in automotive engineering for both functional and aesthetic components.

What are the Advantages of Automotive CNC Machining?

Automotive CNC machining gives you a powerful combination of precision, flexibility, and quality. It enables the fast and cost-effective production of automotive components with consistent accuracy, making it an ideal solution for both prototypes and mass production.

- High-dimensional precision

- Ausgezeichnete Oberflächenbearbeitung

- Supports complex geometries

- Consistent repeatability

- Broad material compatibility

- Low production waste

When Do You Use Automotive CNC Machining?

You need automotive CNC machining services when you require custom or high-precision vehicle parts that can't be made accurately with traditional machines. If you’re developing a new prototype, CNC machining allows you to test and refine designs quickly. It’s also essential when you need to manufacture parts in small batches without the expense of custom molds.

This service becomes especially useful when dealing with components that must meet tight tolerances, withstand mechanical stress, or match exact dimensions. CNC machining offers the control and repeatability needed for automotive engineering. You can also rely on it for upgrades, custom modifications, and performance tuning.