Exceptional Shaft Manufacturer: High Performance, Top-Quality

At DEK, our +19 years of shaft manufacturing experience with several specialties is a guarantee to improved quality shafts with consistent lead times and cost optimization. Through DEK, you will get precisely manufactured shafts in any size, any length, any type.

Precision Shaft Manufacturing Services, Complete Customization & On-Time Delivery

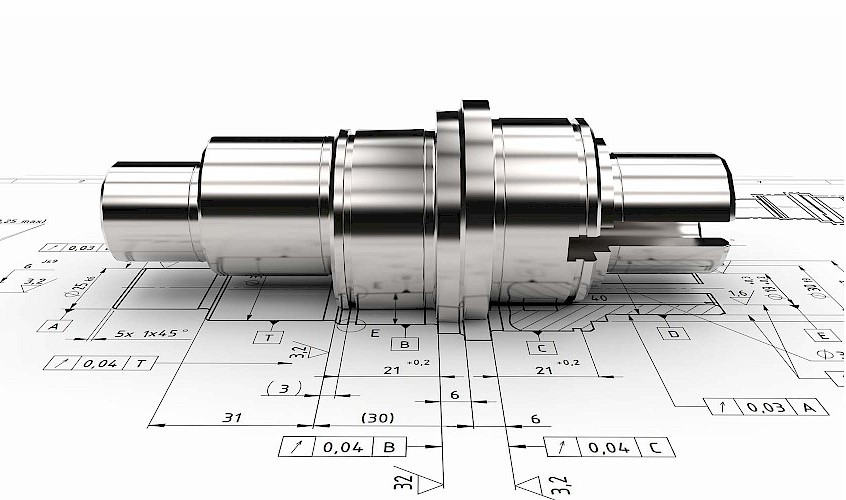

DEK is the best and the most trusted shaft manufacturer from China with technological-enhanced and state-of-the-art shaft machining services. Avoid high prices by sending your shaft’s 2D/3D models to our engineering team for quoting. DEK has the experience you seek to precisely manufacture shafts with tighter tolerance of +/- 0.001mm.

- Quality standard shaft manufacturer with 9100 | ISO 9001:2015 Certification

- Experienced to meet demanding shaft tolerances

- On-demand, rapid, and reliable shaft manufacturing capability

- Dedicated shaft manufacturer for projects that requires complex machining and grinding services

- Handover your shaft manufacturing requirements and let the DEK do the rest

Common Shafts We Can Produce

DEK’s shaft manufacturing capabilities enable you to have every kind of shaft.

The shafts can be either transmission or machine. Still, with DEK, we also have unparalleled shaft customization capabilities that let you customize your shaft without any restriction.

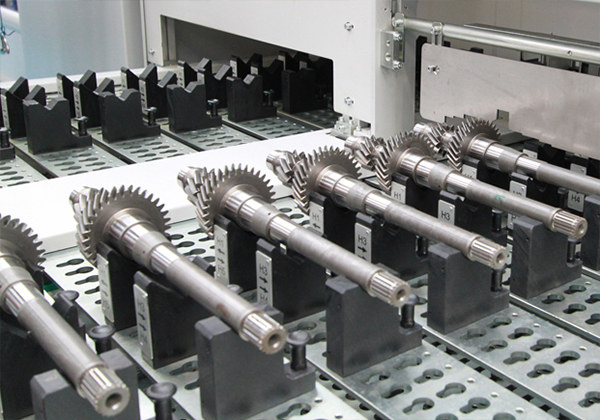

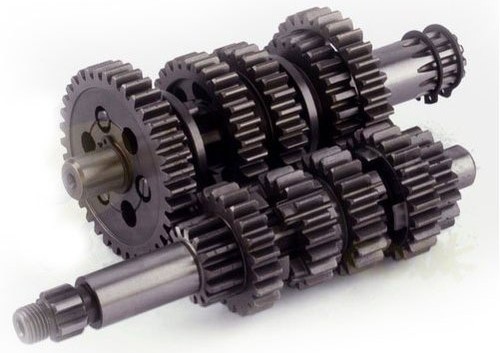

Gear Shaft Manufacturer

The gear shaft provides the rotation to gear by being its axle. The gear shaft is the most important part because of its ability to transfer energy/power from the engine to the drive mechanism. DEK understands it and offers precision shaft manufacturing to produce high-quality gear shafts.

Worm Shaft Manufacturer

Worm shaft offers hundreds of benefits through its ability to provide high reduction ratios as well as correspondingly high torque multiplication. DEK knows its value in applications that require a tuning mechanism and offer the best-in-quality worm shaft.

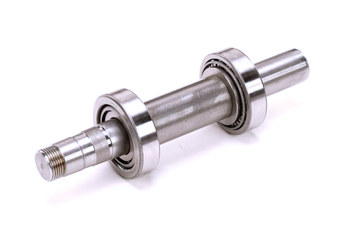

Bearing Shaft Manufacturer

Bearing shaft support shafting between the engine and the tail shaft. At DEK, our engineers make sure that bearing shafts fulfill their purpose by reducing friction and allow for smoother rotation. DEK’s bearing shafts are known for their ability to reduce energy consumption.

Drive Shaft Manufacturer

Driveshaft is the most crucial component of a machine. Its ability to transmit mechanical power, torque, and rotation makes it unique. DEK as a shaft manufacturer makes sure that our manufactured drive shaft will increase your machines’ performance.

Motor Shaft Manufacturer

Motor shaft is a component in most rotating equipment. Moreover, DEK believes that it is the baseline of most motors. Due to its extremely important role in motors, you should never compromise on its quality in the same way DEK never did and produced top-class motor shafts from the start.

Hollow Shaft Manufacturer

DEK believes that hollow shafts need to be strong and long-lasting because it is the most important component of the hollow shaft motor. Furthermore, there are many hollow shaft applications, including electrically powered vehicles.

Fan Shaft Manufacturer

DEK believes that fan shafts are the most important part of most electric motors. The electric motor’s mechanism reflects the shafts working. Hence, it is important for a fan shaft to be powerful enough to output high performance. DEK understands it and allows no space for a mistake in its manufacturing.

Linear Shaft Manufacturer

These are the most common and least complex shafts. DEK offers cost-effective and precision shaft manufacturing for linear shafts that provide linear motion for power transmission applications. Whenever sliding or linear motion is required, linear shafts are used. DEK serving linear shafts to its customers for decades and got trusted by many.

Pump Shaft Manufacturer

DEK loves manufacturing pump shafts because of their importance in centrifugal pump rotary and the complexity involved in its design. The extremely tighter tolerances pump shaft requires to perform perfectly is a piece of cake for DEK. The pump shaft is basically coupled with the motor shaft through proper intake and seal shafts.

Screw Shaft Manufacturer

It’s simply amazing to see a screw shaft in action. Its satisfying ability to convert rotational motion/force to linear motion/force is just exceptional, and DEK loves manufacturing them. DEK, from the start, is manufacturing screw shafts and consider it a classic machine component.

Stub Shaft Manufacturer

It is a short rotating shaft that requires robustness and perfect finishing to perform exceptionally. These can be used as input/output connectors that allow for a compact assembly. DEK makes sure that its manufactured stub shafts provide just enough material for the attachment of a coupling for the system’s design loads.

Our Shaft Manufacturing Technologies

DEK can perform the necessary machining/tooling for nearly every process encountered in shaft manufacturing.

Grinding

Grinding

Turning

Turning

Auto Lathe

Auto Lathe

Drilling

Drilling

Boring

Boring

Internal/External Threading

Internal/External Threading

Spinning & Teeth Cutting

Spinning & Teeth Cutting

Rotary Broaching

Rotary Broaching

Common Materials For Manufacturing Shafts

DEK’s state-of-the-art shaft engineering and manufacturing technologies bring the possibility to utilize materials that require the highest degree of quality control and precision. DEK can process the most challenging materials to the highest degree of complex shafts.

Steel

Steel offers toughness and wear-resistance to your shafts. DEK’s industrial-grade steel offers excellent machinability. DEK as a shaft manufacturer, ensure absolute reliable and accurate steel shafts with extensive quality. Stainless steel, mild steel, and alloy steel (nickel, nickel-chromium, or chromium-vanadium steel) are the most popular and common for shaft manufacturing.

Benefits

- Extremely high strength

- Moderate strength applications

- Good formability

- High tensile strength

- Great fatigue resistant

- Popular general-purpose

- Exceptional impact resistant

- Predictable & Reliable

- Cost-efficient

- Energy efficiency

Aluminum

Aluminum alloys for shaft manufacturing are perfect materials that offer excellent and improved machinability. As a shaft manufacturer, DEK knows the importance of aluminum for shafts that require improved strength, high fatigue, and crack resistance.

Benefits

- Inexpensive

- Heat Insulating

- Chemical resistant

- High heat and friction

- Excellent moisture resistance

- Food safe grades available

- High impact strength

- and more..

Why More Than 2300+ Clients ♥️ DEK

Premium Quality

Choosing DEK as your shaft manufacturer means getting the top-notch and unmatched quality you deserve. You can trust that the DEK will deliver shafts without compromising on its quality based on the regulations laid out by the China government. When it comes to quality, efficiency, and giving you the right price, DEK beat the competition every time.

Attention to Details

It's DEK's attention to details that makes us stand out from the rest. At DEK, our shaft manufacturing techniques are technological-enhanced, cost-efficient, and fast. DEK believes that it's important for a shaft manufacturer to ensure optimal production speeds, keeping downtime to a minimum and boosting overall productivity. Attention to details helps to achieve these as well as ensure flawless machining to boosting shaft performance.

A Plan for Success

DEK's ability to make smart decisions regards to your shaft's designs and manufacturing can quickly eliminate unforeseen issues before they even cause any larger problems. Our talented staff of engineers with the supreme ability of problem-solving benefit your business and make the right adjustments in your shaft manufacturing plans. DEK is the best shaft manufacturer to tackle any issues involved in the whole process and confident enough to satisfy you with its services.

Creative

DEK is extremely creative to offer you services in the way that you can cost-effectively get premium shafts. DEK's creativity enables us to make quick decisions to ensure smoothness and efficient operations throughout the complete shaft manufacturing process. DEK believes that the more creative services we offer, the more valuable we will be to you by keeping up with the competition, continual innovation, and improvement.

Cost-Effective

DEK offers cost-effective shaft manufacturing through its fully optimized processes. Our ability to reduce energy consumption by implementing a continuous improvement strategy for your shafts. By working smarter through automation and state-of-the-art equipment, DEK reduces overall manufacturing costs without sacrificing shafts' quality and performance. DEK's selection of top-grade material with a standardized shaft manufacturing process is guaranteed to eliminate the costs by eliminating errors, defects, reworks, and wastage of quality resources.

Meeting Deadlines

Achieving realistic deadlines for your haft manufacturing projects is what DEK always does. Our focused objective, on-time performance, and getting high-quality and perfectly manufactured shafts also increase your profitability. To surpass your expectations, our in-detail planning estimate delivery time accurately towards achieving a shared goal and keeping complex shaft manufacturing projects on track.

Experts Only

Our staff is consisting of experts that can understand the latest shaft manufacturing technologies, adopt them, and able to upgrade them. When DEK receives your request for a quote, our experts immediately process your requirements and get a general idea of what you need. Afterward, we build a standard communication network with you to finalize the requirements by giving you the best services.

Complete Customization

DEK's shaft customization capability features a vast library of custom options. You are not limited to us and can have the freedom to customize your shafts in every way you want by customizing your shaft's design, shape, size, etc. DEK prioritizes precision shaft manufacturing to maintain the high performance and quality of your custom shafts. Even extreme complexities can be achieved and handled with ease through our advanced machining.

Feedbacks From Our Happy Clients

Looking For The Best Shaft Manufacturer For Your Custom Shaft Designs?

DEK is a premium manufacturer of standard and custom shafts. What DEK delivers to shaft industries is unmatched when it comes to designing and manufacturing top-quality shafts of all kinds. DEK’s rapid response, optimum performance, and versatility is the key to survive in an intense global competition. DEK is trusted for 19+ years for its premium shaft designing and manufacturing. DEK as a shaft manufacturer is capable of producing 2.5 million+ shafts each year and able to proceed with your orders within 1-2 weeks.

Guide To Precision Shaft & Buying F.A.Q

Shaft manufacturer is known for its ability to provide tooling for every process encountered in shaft manufacturing.

Shaft manufacturer holds power to precisely manufacture shafts with tighter tolerances at higher production rates.

This FAQ guide will update you about the latest technologies and procedures involved in shaft manufacturing to increase your business productivity.

What Is A Shaft?

In general, the shaft is known to be a toothed wheel that enables machines to transmit rotational power continually.

The shaft manufacturers mix and match shafts of different sizes to vary the force involved and maintain or achieve a specific rotational speed.

Shafts play an important part in a vast library of mechanical equipment, from vehicles to airplanes.

Transmitting torque and rotary motion within a machine is what shafts do the best.

There even can be various elements mounted on a shaft, such as:

- Pulleys

- Cams

- Gears

- Sprockets

Moreover, shafts generate a great amount of power and channel force in the mechanical equipment.

The shaft manufacturing involves the innovative techniques and latest technology to make shafts more productive.

In order to achieve precision shafts with tighter tolerances, shaft manufacturing involves many machining processes, including:

- Drilling & Turning

- Boring

- Spinning & Teeth Cutting

- Internal/External Threading

- Rotary Broaching

Furthermore, many secondary operations like heat treating and electro-polishing are able to increase the shaft’s performance.

What Are the Applications of Shaft?

The shaft is known to be the most crucial component of a machine that helps transmit power or movement to another part.

Shafts either be incredibly simple or can be extremely complex based on their applications and high requirements due to quality standards.

Shafts are mostly found in engines and transmissions and related to the following applications:

- Aerospace

- Agriculture

- Conveyor Systems

- Construction

- Consumer Products

- Defense

- Electrical & Electronics

- Handling & Automation

- Heavy Equipment

- Industrial Applications

- Mining

- Metal Industry

- Medical Technology

- Mechanical Engineering

- Marine

- Manufacturing Industry

- Oil & Gas

- Off-Highway

- Pneumatics

- Paper Industry

- Pump Drivers

- Railway Applications

- Robotics

- Special Environments

- Sports

- Transportation

- Telecommunication

Moreover, these are the industries where relatively structured shafts manufactured by turning, grinding, or any other means are useful.

What is the Impact of Shaft's Quality and Performance?

In general, the technologically enhanced shaft manufacturing process is able to produce high-quality shafts in a cost-efficient manner.

The shaft is important to be high-quality and performance because it’s the crucial part of most equipment.

Having the perfect manufactured shaft can increase the speed, life, and processing power of many critical components involved in the same process.

Many parts related to the aerospace industry and robotics require shafts of tighter tolerances because a single irregularity can cause a complete system failure.

Hence, in order to save equipment from a catastrophic failure and improve its performance, shafts need to be high-quality.

So, every industry needs to understand the importance of high-quality and precise shaft manufacturing to achieve tighter tolerances.

What is the Impact of Precision Shaft's tolerance?

The shaft works in an environment along with other connected parts that transfer power by operating with one another at the same time.

Hence, it is important to identify the shafts manufactured to be within the acceptable alignment tolerance.

The tolerance and precision in shaft manufacturing can be responsible for:

- Increase Operating Time

- Increase Productivity

- Increase production Quality

Furthermore, achieving tighter tolerances with precision shaft manufacturing can eliminate the risk of size differences.

Precision manufacturing also a more cost-effective way of producing shafts with extremely tighter tolerances.

What are the Materials for Shaft?

High-quality industrial-grade materials that are able to handle and transmit power with utmost performance are perfect for shaft manufacturing.

It’s important to understand the material type for shaft manufacturing to achieve high performance.

Shaft manufacturing only prioritizes industrial-grade materials that have the following properties:

- High strength and robustness

- Excellent machinability

- The low notch sensitivity factor

Most commonly, mild steel and aluminum are the materials for manufacturing ordinary shafts.

Furthermore, in applications where extremely high strength is required, alloy steel such as the followings are preferred:

- Nickel-Chromium

- Chromium-Vanadium Steel

Furthermore, the following materials are also considered perfect for shaft manufacturing:

- Cold-Rolled/Hot-Rolled Steel

- Medium Carbon

- Medium Tensile Steel

Additionally, most of the applications that require good strength, toughness, and wear resistance in a shaft use the following steel types:

- Stainless Steel

- Silver Steel

- Key Steel

- Bright Mild Steels

The shafts can have many shapes usually sold in cross-section, and sometimes they can be hollow cylindrical.

How Crucial are Material's Physical Properties for Shaft operating?

In order to achieve the highest precision in shaft manufacturing, it’s important to understand the physical properties of its material holds.

Physical properties play an important part in the shaft’s structural design optimization with the objective of improving its performance.

Moreover, these properties also define the physical state of the shaft and encompass:

- Texture

- Density

- Mass

- Melting Point

- Boiling Point

- Electrical Conductivity

- Thermal Conductivity

Additionally, it is important for shaft manufacturing materials to be strong at the following physical properties:

- Tensile Strength

- Yield Strength

- Corrosion Resistance

- Thermal Expansion

The shaft’s longer lift and maintaining performance at the same level mostly depends upon how strong its physical properties are.

How Crucial are Material's Mechanical Properties for Shaft operating?

The shaft’s mechanical properties list is a long one and contains some very rare ones.

From the engineer’s perspective, these rare mechanical properties describe the material’s performance.

The decisions involve in shaft designing and manufacturing are most of the time based on its mechanical properties.

The following are some of the mechanical properties that shaft manufacturers require in material to produce shafts of utmost quality and precision:

- Material Stress and Strain

- Young’s Modulus (Define material’s stiffness and elasticity)

- Yield Strength

- Tensile Strength

- Plasticity (Define material’s ductility and malleability)

- Toughness

- Hardness (Accounts for material’s durability)

- Brittleness (Mostly unwanted in mechanical engineering)

- Fatigue Strength (Endurance strength)

- Impact Resistance

- Fracture Toughness

Moreover, different types of materials can be classified and identified through their mechanical properties.

These properties define how a specific material reacts when a certain type of force or load is applied.

Most importantly, studying what mechanical properties the shaft holds can increase its usability and performance for a particular application.

What is the Shaft Machining Process Utilized by DEK?

At DEK, our first step is to detail study your shaft machining requirements before taking any further steps.

DEK’s engineers finalize the shaft’s design through a simulation design that will clear the following things:

- How long the shaft’s machining process will be

- A good estimation of price

- What things to prioritize

Sometimes, shafts with complex designs require utmost precision and tighter tolerances, so the DEK priority shafts according to what is required by the customers.

After an in-detail study of the shaft, DEK starts the shaft machining process.

Moreover, DEK uses many shaft machining processes, and some of them are following:

CNC Turning

It is the most common shaft manufacturing process that involves specialized tools that perform rotational cutting to create and shape the shaft.

The process of CNC turning starts from placing the material in a chuck and rotate against a tool that removes the material to create a shape.

Because of its material removal technique in a rotational mode, it is also called subtraction machining.

Auto Lathe

It is an automatic shaft machining process with a repeating cycle to produce duplicate shafts.

An automatic lathe is a technological-enhanced machining process that involves high-speed cutting tools.

DEK use the auto lathe for the following reasons:

- When production requirements are high

- High-performance with exceptional precision is achievable

High dimensional control accuracy is achievable

It values accuracy and precision. This shaft manufacturing process uses a spinning wheel that consists of tools that shape the shaft by removing the excess material.

There is a number of techniques that fall under precision grinding.

Precision grinding is the most valuable when it comes to achieving a high surface quality finish with extreme tighter tolerances.

Mixed Machining Processes

Some shaft designs require multiple machining processes because of the complexity involved.

Can DEK offer customized shafts?

In short, yes!

At DEK, our shaft manufacturing capabilities feature the latest technologies and state-of-the-art machinery to manufacture custom shafts.

DEK offers a vast library of custom options for shaft customization.

In most cases, the shafts go into custom motors, so it also requires a unique design for their shafts.

Industries require precision when it comes to building custom shafts.

Depending on the applications, the shafts can be customized based on their:

- Diameter

- Length

- Tolerance

- Design

- Shape & Size

- Surface Finish

- Coating

The custom shaft manufacturing must be durable enough to produce custom shafts that fit the right requirements for a custom application.

Moreover, DEK has enough experience and skill to maintain utmost precision even for extremely complex custom shafts.

What Shafts You Can Machining?

At DEK, we can manufacture shafts of different types, sizes, and designs.

The design of mechanical shafts depends on the system requirements, and these requirements further define its type.

DEK uses exceptional shaft manufacturing techniques to maximizes shaft efficiency and performance without sacrificing its overall quality.

The following are the shafts that DEK can manufacture while maintaining the utmost precision:

- Boat Shaft

- Bearing Shaft

- Drive Shaft

- Eccentric Shaft

- Flexible Shaft

- Fan Shaft

- Gear Shaft

- Hollow shaft

- Linear Shaft

- Motor Shaft

- Pump Shaft

- Rotor Shaft

- Splined Shaft

- Screw Shaft

- Stub Shaft

- Worm Shaft

Moreover, DEK as a shaft manufacturer has unparalleled customization capabilities.

These shaft customization capabilities allow DEK to manufacture shafts of any type and kind based on your custom requirements.

What Shapes of Shaft's End You Can Machining?

Shafts are known to have exceptional precision and extreme performance even under complex environments.

Environments and equipment affect the shaft’s performance the most.

In order to get a smooth transmission, the shaft’s end plays an important part.

A standard shaft has a left end and a right end that work as a sealing function and is necessary to maximize the equipment’s performance.

The shafts can be linear or rotary and can have different shaft end shapes.

The following are the shaft’s end shapes DEK offers:

No Machining

Most importantly, DEK can process your requirements related to custom shaft’s end shapes.

At DEK, we believe that a perfectly shaped shaft end is a perfect solution to meet your specific requirements related to maximizing sealing and bearing.

What tolerance of Shaft Diameter Can You Achieve?

In general, the standard shaft tolerance required by general applications is within ±0.05mm.

However, DEK considers this value risk and also that it can limit the shaft’s performance.

At DEK, we know that shaft tolerance within ±0.002mm is perfect and achievable.

Even for the shafts with utmost complexity, DEK can reach a diameter tolerance of ±0.001mm.

DEK is good at processing ultra-precision shafts that some industries like robotics and aerospace required the most.

What diameter tolerance your shaft required depends on the complexity involved in its design and application.

After a detailed study and review of your shafts design, DEK finalizes the requirements and give you the best results possible.

Please send us an inquiry, so our expert staff can give you a perfect solution based on your needs.

How the DEK Achieve Tighter Tolerances?

It is important for a shaft manufacturer to work with dimensional tolerances.

The shaft’s accuracy and precision depend on its dimensional tolerance, and achieving tighter tolerances can help optimize the shaft’s performance.

At DEK, our latest technology and state-of-the-art machining equipment help us machine extremely complex shafts with tighter tolerances.

DEK’s machining processes are fully optimized and can even achieve the tighter tolerances of ±0.001mm without facing any causalities.

Our fully optimized shaft manufacturing process means:

- Elimination of extra processes

- Cost-effective solutions

- Critical reduction in material waste

- Minimum waste of energy and other resources

- Utmost shaft quality and performance achievement

However, DEK understands that there is no reason to apply a ±0.001mm tolerance when ±0.01mm can be perfect.

Hence, DEK knows the best that what tolerance your shaft requires and how to offer cost-effective shaft manufacturing services.

How DEK Measures the Quality of Shafts?

DEK believes that the end result is most important in shaft manufacturing, and that’s why we value the process so much.

Offering customers the flexibility and creativity through shaft customization also can give the best results and top-quality shafts in return.

In order to measure the quality of manufactured shafts, DEK performs a detailed inspection.

This detailed inspection of manufactured shafts gives us the following:

- Ensure shaft quality

- Verify quality at the source, so you don’t get any defective shafts

- Avoid reputational damage

- Anticipate production delays

- Optimize shaft’s quality

- Involved quality intelligence identify minor issues

- Improve shaft flexibility and manage performance

Prevention from errors through precision shaft manufacturing is better and more effective than damage control.

Hence, DEK also monitors every process involved in shaft manufacturing to output parts that are exceptional in quality and performance.

Whether the Shaft Can be Coated or Not?

There are some post-processes of shaft manufacturing and includes coating and surface finishing.

Coating shafts can further increase their mechanical and physical properties that automatically affect their performance and quality.

Different coatings can increase the various material properties. Your requirements can help to select the most suitable coating for shafts.

A perfect coating can protect the shaft from corrosion and can increase its flexibility, strength, and hardness.

The following are some coating options for shafts:

- PVD Coating

- Electrodeposited Coating

- Black Oxide

- E-Coat

- Powder Coat

- Dielectric Coat

Some shaft materials provide lesser hardness, resistance to certain elements, and many more.

Hence, eliminating these material drawbacks through the coating is the perfect solution to achieve maximum performance.

How does Shaft Vulnerable Against Corrosion and Acid?

It is important for a shaft to provide resistance against corrosion and acid.

In general, shafts need to adopt the acidic or alkali environment in some applications.

The shaft material like stainless steel provides resistance against corrosion and acid naturally, and that’s also one of the many reasons behind its high performance and longer life-span.

Shafts can be vulnerable to corrosion and acid because of the following reasons:

- Because of the natural properties of the material

- Because of the shaft manufacturing process

- Because of the shaft’s coating and surface finishes

How Important Consistent Lead Times and Cost Optimization for Shaft Manufacturer?

Improved quality and consistent lead times are some of the shaft manufacturer specialties.

Improving shaft quality and performance by increasing the shaft manufacturing process efficiency is the best way.

Industries demand a fast and reliable shaft manufacturer to manufacture shafts with different tolerances.

Moreover, consistent lead times are required to produce high-quality parts in a cost-effective manner.

Optimizing the shaft manufacturing process can increase the cost-effectiveness of manufactured shafts.

When it comes to manufacturing shafts that require complex machining, consistent lead times and cost optimization is required to output the top-quality shafts.

Why Choose DEK as Your Best Shaft Supplier?

DEK is one of the top shaft manufacturers from China that offers its services internationally.

DEK facilitates its customers through complete shaft customization through a vast library of custom options.

DEK took fatigue, stress concentration, standard part availability, and manufacturing considerations into account to finalize your shaft design.

There are many reasons for you to choose DEK as your shaft manufacturer, and some of them are following:

- Because of DEK’s advanced and technologically enhanced shaft manufacturing techniques

- Because of DEK’s state-of-the-art machining equipment to achieve extremely tighter tolerances and precision

- Because of DEK’s ability to offer cost-effective solutions through its fully optimized shaft manufacturing process

- Because of DEK’s commitment to consistent lead times

Moreover, DEK follows quality standards to ensure the manufactured shaft’s high quality.

Although, DEK performs a detailed inspection to guarantee high-quality shafts.

How will DEK Process Your Orders?

DEK is a one-stop shaft manufacturing services provider that offers its services on demand.

Through our services, DEK is committed to manufacturing high-quality shafts with greater performance.

You can order from DEK through the “Request a Quote” option on our website.

After submitting the essential information required by our engineers to process your shaft design, DEK will get in touch shortly to give you all the possible solutions.

Our advanced software will study your designs and find any critical issues involved in their design.

Afterward, we develop a detailed shaft manufacturing plan and start the machining process as soon as you clear the payment.

In the end, after the detailed inspection, your order is packed and sent for shipment.

At DEK, our success is your complete satisfaction, and we achieve it by offering you top-quality shafts.