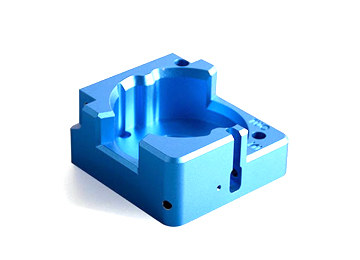

Metal CNC Machining

DEK has strong metal CNC Machining capabilities and rich experience, and provides customized solutions, you can freely choose hundreds of different metals and alloys to fit your needs, whether your machining needs are simple or complex, whether the quantity is low volume or mass.

With our various of advantaged CNC and manual mills and lathes, we can handle all of your specific metal CNC machining needs, and ensure you will get the highest quality part at a short lead time.

Available Material List For Metal CNC Machining

Aluminum is one of the most known and used metals due to its efficient characteristics in many production processes. It is a metal with excellent hardness and flexibility at the same time.

Advantages

- Lightweight

- Cost-Effectiveness

- Good corrosion resistance

- Excellent processability

- Appropriate weight-strength ratio

- and more..

Applications

- Electronic products and appliances in general

- Key components for construction

- Products for electrical use

- Various household objects

- and more..

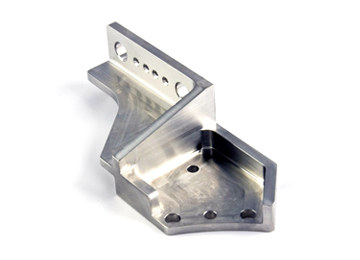

Stainless Steel

Mild Steel is a metal that is steel, in combination with a certain percentage of carbon. In particular, it is steel different from stainless steel. In particular, this metal is used in some specific applications.

Advantages

- Excellent corrosion resistance

- High level of durability in general

- Efficient at exposure to different temperatures

- Useful magnetic and mechanical properties

- and more..

Applications

- Household appliances

- Industrial Machinery

- Automotive Industry

- Components and products for home use

- Aerospace industry

- Armament industry

- and more..

Mild steel

Mild Steel is a metal that is steel, in combination with a certain percentage of carbon. In particular, it is steel different from stainless steel. In particular, this metal is used in some specific applications.

Advantages

- Greater durability than other types of steel

- Efficient as a cutting tool

- Allows for a reduction in production costs

- An excellent option for recycling

- and more..

Applications

- Automotive Industry

- Key components such as fencing nails and cables

- Decorative objects

- Signal objects

- Key components such as structural steel

- and more..

Alloy steel

The steel alloy has the objective of improving the mechanical properties of some objects. This is why we can find high alloy steels and low alloy steels. In most applications, this second option is used.

Advantages

- Excellent overall mechanical properties

- Efficient corrosion resistance

- Durability and resistance in low or high temperatures

- and more..

Applications

- Components related to the energy industry, such as pipes

- Construction area, e.g. bridges

- Manufacture of home appliances

- and more..

Tool steel

Tool steel is widely used to tooling, measuring tools, molds, and wear-resistant tools. Tool steel has high hardness and can maintain high hardness at high temperatures, as well as high wear resistance and appropriate suitability.

Advantages

- Efficient at different temperatures

- High level of hardness

- Efficient impact resistance

- and more..

Applications

- Tooling

- Measuring tools

- Injection Molds

- Core pins, ejector pins, core inserts for mold

- and more..

Brass

Brass is an alloy of copper and zinc, Brass has good mechanical properties and wear resistance. It can be used to manufacture precision instruments, parts of ships, shells of guns, radiators, cold cut tubes in molds, etc.

Advantages

- Excellent level of flexibility

- High level of corrosion resistance

- Low cost

- and more..

Applications

- Musical instruments

- Specific applications, such as locks and valves

- Components that are used with explosives

- and more..

Copper

One of the best-known metals is copper and is used because it is very ductile, malleable, and soft. It is usually very advantageous because it is an excellent conductor of electricity and heat.

Advantages

- An excellent conductor of electricity and temperature

- Highly malleable metal

- Excellent resistance to scaling and corrosion

- High level of durability in general

- and more..

Applications

- A large number of components in the automotive industry

- Electronic Industry

- Kitchen products for the home

- Jewelry application

- and more..

Titanium

As a metal, titanium is recognized for its high strength-to-weight ratio. It is a strong metal with low density that is quite ductile, and it is non-magnetic and a poor conductor of heat and electricity.

Advantages

- High resistance to corrosion

- High density to strength ratio

- Excellent as a refractory metal

- High level of hardness and resistance

- and more..

Applications

- Aerospace and aeronautics industry

- Shipping industry

- The arms industry, such as missiles and armor

- and more..

Magnesium

Magnesium used in metal applications has the characteristics of low density, high strength, large modulus of elasticity, good heat dissipation, good shock absorption, greater impact corrosion resistance than aluminum alloys, and good organic and alkali corrosion resistance.

Advantages

- Excellent weight to strength ratio

- High impact resistance

- Excellent dimensional stability

- Optimal damping level

- and more..

Applications

- Electronic industry, such as laptops

- Power tools in general

- Components for the automotive industry

- Everyday products

- and more..

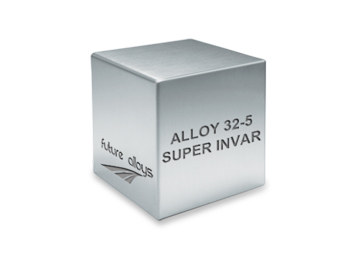

Invar

In particular, it is an alloy mainly made up of 36% nickel and 64% iron.

Here this type of metal is used in a large number of parts that require a high level of precision.

Advantages

- Low coefficient of thermal expansion

- Excellent use for precise functioning parts

- An optimal level of durability and resistance

- and more..

Applications

- Watch industry

- Components for the electronics industry

- Molds in aerostructures

- Specific tools such as seismic flowmeters

- and more..

Inconel

This type of metal is formed mainly of chrome and nickel. It also belongs to the registered trademark of the company Special Metals Corporation.

This is a type of alloy that offers great advantages for many industries today.

Advantages

- Excellent corrosion resistance

- Efficient in the face of kinetic energy

- Good performance in high-pressure environments

- and more..

Applications

- Components for the marine industry

- Oil and gas industry

- and more..

Couldn’t find the metals you want? Contact us now, we have a strong metal material supply chain, can CNC machining any metal parts for you.